Why Repeatability and All-Electric Molding Machines Go Hand in Hand

ELK GROVE VILLAGE, IL, January 23, 2022 - Repeatability in injection molding. Being able to offer this shot after shot means lower cost of operation and consistency. It is key to the production of parts in today’s competitive market and has a crucial influence on efficiency and overall profitability.

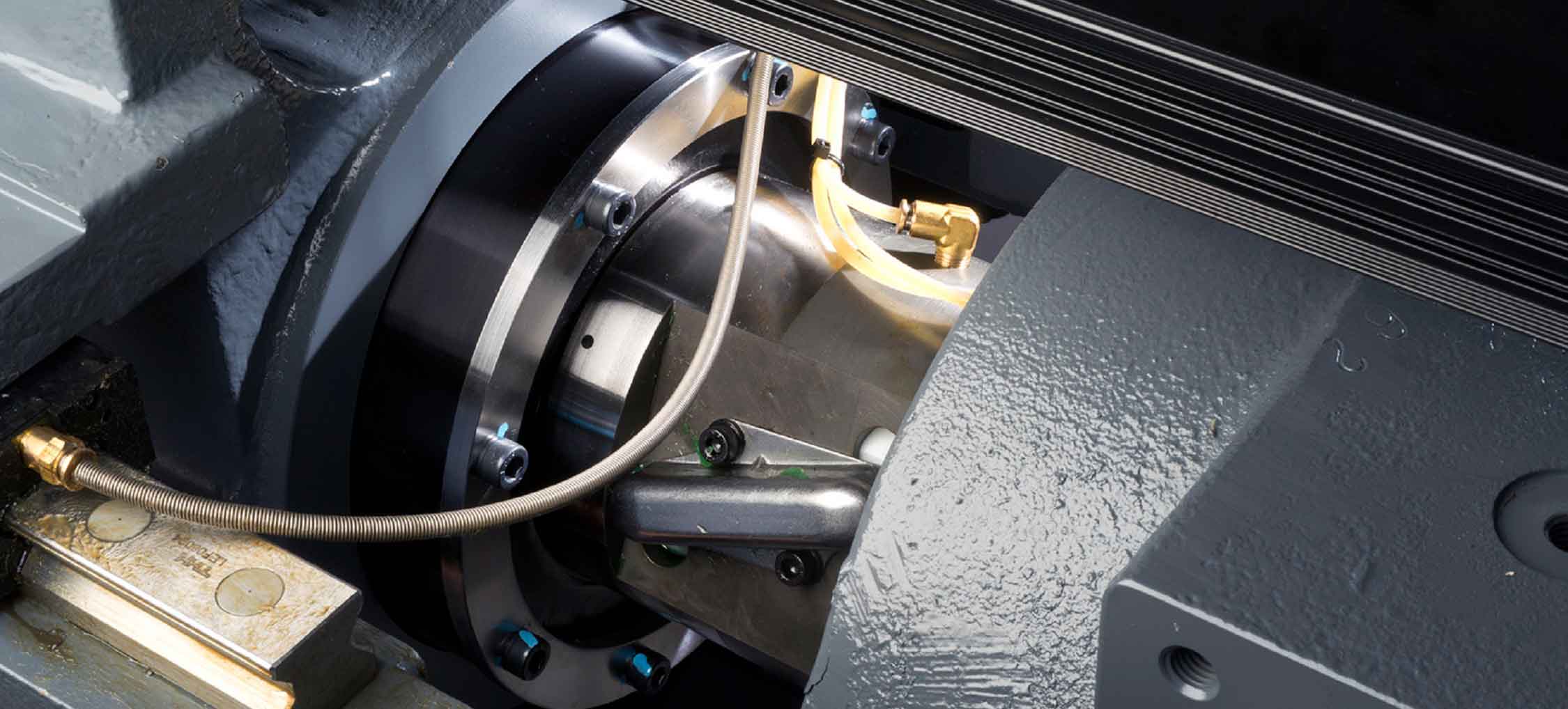

High repeatability over a long period of time requires a highly robust machine paired with sophisticated controls. The SXIII all-electric series offers unparalleled repeatability with modern machine controls. Instead of being driven by a hydraulic system, the SXIII series uses digital controls with high speed, highly efficient servo motors. Each axis is controlled by an independent motor for injection, charging, clamping, and ejection which equates to a more repeatable, faster process.

Quality Improvements

When you are able to achieve shot-to-shot repeatability, you can expect quality improvements. The electric servo motor on the SXIII allows 0.1mm +/- rotation to actuate movements. Optical rotary encoders offer additional position sensing with a control resolution of .00005 mm ensuring complete precision, repeatability, and improved overall quality.

Cost Reduction

Improved repeatability results in a cost reduction delivering higher quality products with less scrap. The SXIII injection unit is supported by linear guides which reduces the drag of injection and back pressure creating a more precise process. Being able to ensure an accurate injection speed and back-pressure control improves shot-to-shot repeatability throughout the processing cycle. Compared to hydraulic machine cylinders which are slower and less responsive, this is a great advantage to reduce costs while improving part quality.

Improved Productivity

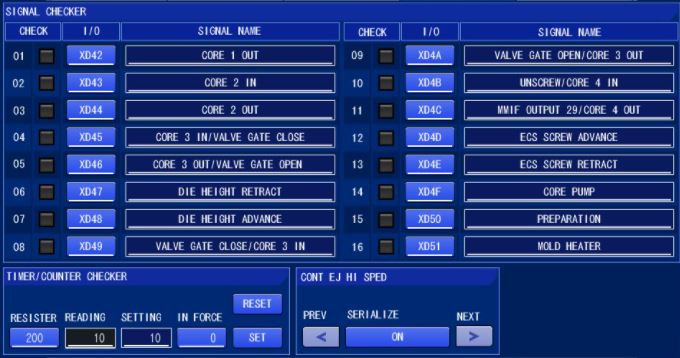

Bottom line, a more repeatable process improves overall productivity. The state of the art, user-friendly V70 controller paired with the advanced load cell on the SXIII helps the operator achieve scientific molding without the requirement of in-mold transducers.

The SXIII series also brings a smoother, controlled acceleration and deceleration through the current to the servo motor. That means force is immediate, accuracy is improved, and productivity soars.

Learn More

All-electric machines bring the highest level of accuracy and repeatability on the market. Contact our injection molding team to learn more about the specific benefits the SXIII all-electric series brings to manufacturers to achieve these goals.

Tel: (888) 593-1616

Contact us today to discuss how the superior repeatability of all-electric technology can help your operation!

Related Articles View All Articles

Looking to Reduce Scrap? Why All-Electric Injection Molding Machines Are the Clear Choice

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving scrap rates in injection molding can have a large impact on increasing profitability. While there are many process improvements for scrap rate reduction, it is also important to consider the type of machi...

Read moreFaster Cycle Times with All-Electric Injection Molding

ELK GROVE VILLAGE, IL, January 6, 2022 - Considering changing out from hydraulic to all-electric machines in the new year, but trying to justify the change? Look no further than the improvements these machines can make to your cycle time. Being able to red...

Read moreHow Automatic Load Cell Calibration Helps Prevent Molding Defects

ELK GROVE VILLAGE, IL, December 29, 2021 - One of the key advantages of all-electric injection molding machines is the ability to monitor actual plastic pressure during injection via a load cell behind the screw, without the need for in-mold transducers. ...

Read moreHow the I/O Checker Minimizes Machine Downtime for Injection Molders

ELK GROVE VILLAGE, IL, December 21, 2021 - Creating injection molded parts not only requires a high level of technical expertise, but also attention to detail. One small mistake can slow down, or even stop production.How many times this year have machine d...

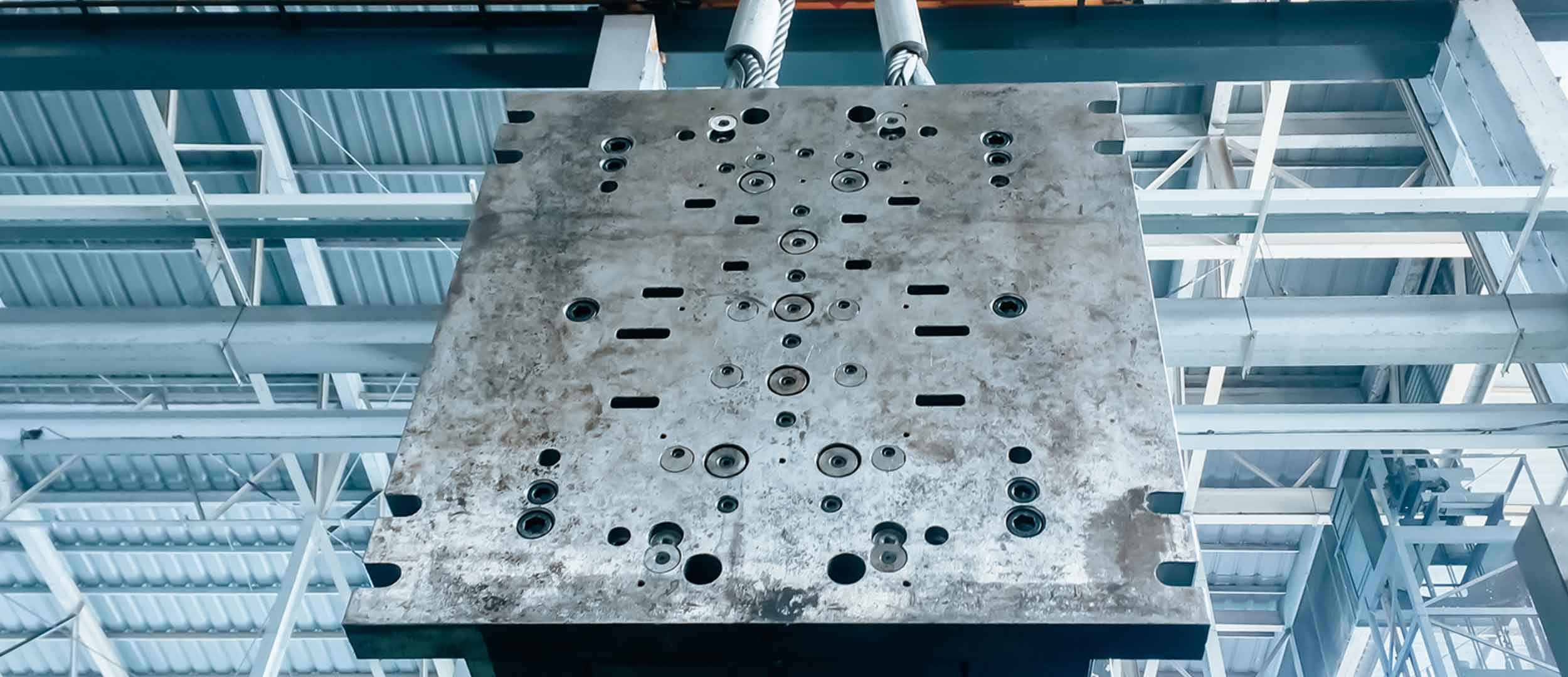

Read moreHow the Mold Guide Makes Set-Up Simple and Efficient

ELK GROVE VILLAGE, IL, December 16, 2021 - Installing a mold in an injection molding machine is a routine process. However, even when tasks are routine, mistakes can be made. Being able to perfect mold change-overs and lessen mistakes can not only help imp...

Read moreShibaura Machine is Making It Simple to Minimize Injection Molding Defects

ELK GROVE VILLAGE, IL, November 30, 2021 - Small mistakes in injection molding can add up to costing companies big money when it comes to time and product lost. Understanding design guidelines and best practices help in preventing defects, but not all mold...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools