Improving OEE with All-Electric Machines

ELK GROVE VILLAGE, IL, January 31, 2022 - Stops in production, whether planned or not, create Availability Loss on the factory floor. While it isn’t always possible to eliminate changeover time, being able to significantly reduce it along with unplanned downtime can greatly affect Overall Equipment Effectiveness (OEE).

All-electric injection molding machines continually come out on top when compared to their hydraulic counterparts, especially when uptime is in question. As the most reliable type of machine on the market, using electric servo motors and ball screws give them the ability to make compound movements without needing to worry about hydraulic oil, ambient temperatures, sticking valves, or noisy pumps is a huge game changer to achieve higher uptime.

As all-electric machines advance, many major manufacturers are taking note. Several additional factors to consider when reviewing how all-electric machines achieve greater uptime to improve OEE Availability include:

Less energy and maintenance

Compared to hydraulic machines which have numerous moving parts and consume large amounts of energy for cooling, our SXIII series all-electric machines only require energy when working and have minimal components.

Another factor to consider is that all-electric machines don’t require machine cooling of hydraulic oil. The cooling water used on hydraulic machines consumes large amounts of energy and require frequent maintenance.

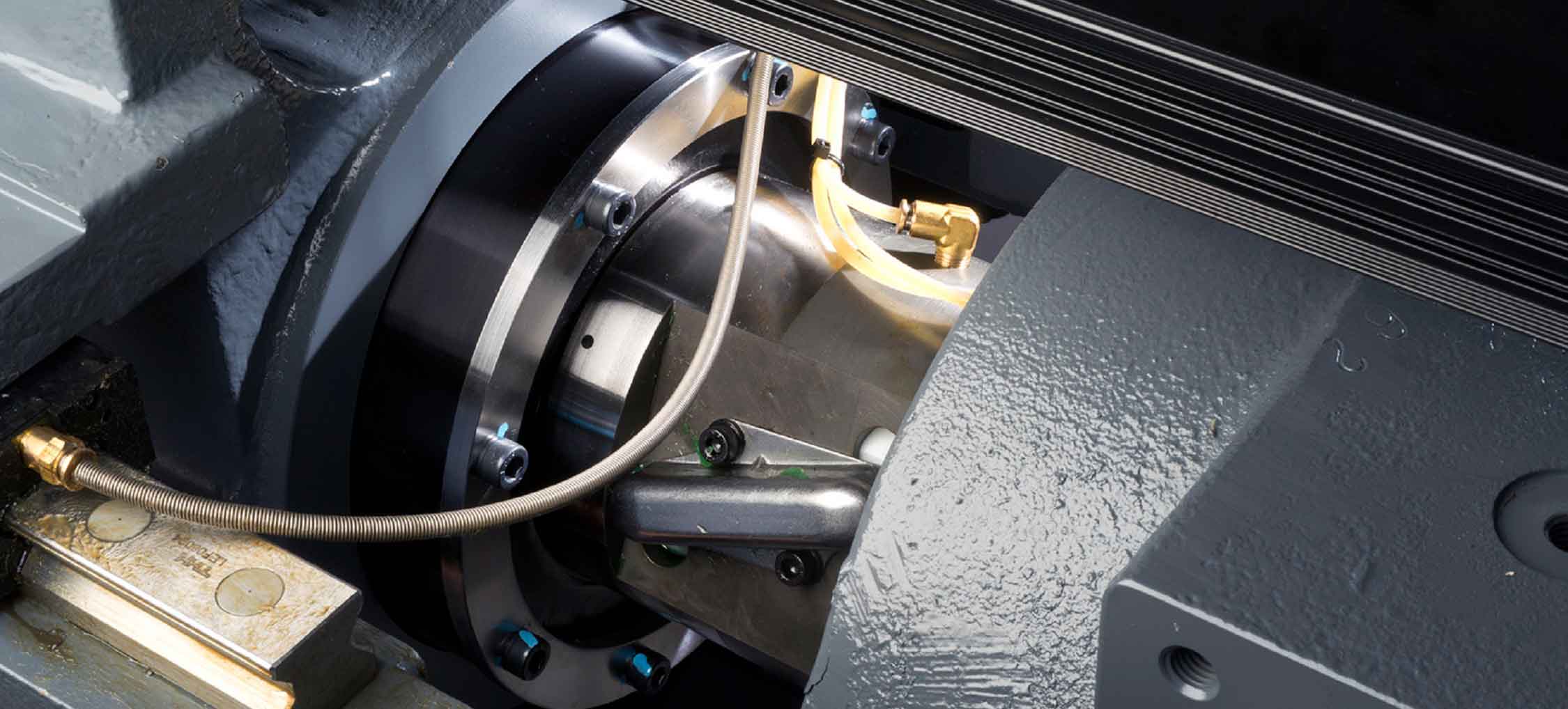

No hydraulic oil

It’s a big difference not having to use hydraulic oil which is not only costly, but can lead to leaks causing downtime and safety hazards. Oil not only creates a slippery, hazardous work environment during mold changes, but has to be warmed upon every start-up, replaced periodically, and disposed of. The SXIII series uses servo electric motors to actuate all of the machines motions, therefore no hydraulic oil is required. This means shorter start-up times and less downtime for maintenance and unplanned safety issues.

Quiet and fast

The SXIII series is extremely quiet while running meaning operators are no longer required to wear hearing protection while operating the machine. This offers an improved manufacturing environment with less fatigue on plant personnel throughout the day.

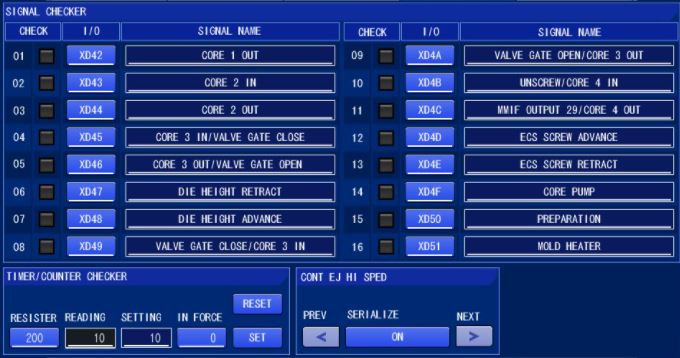

These machines can do more with improved precision. With a typically higher injection speed and faster clamp motion, the SXIII is also digitally controlled by the V70 which means a more predictable production process with extremely high positioning accuracy. The V70 controller brings numerous functionalities and features at the users fingertips to allow them to increase operating efficiency and reduce downtime.

Start Achieving Greater Uptime

The SXIII all-electric injection molding machine can help your factory start improving OEE. Contact our team to learn more about what features the machine and V70 controller have to help you reach your production goals.

Tel: (888) 593-1616

Contact us today to discuss how our all-electric technology can improve your OEE!

Related Articles View All Articles

Why Repeatability and All-Electric Molding Machines Go Hand in Hand

ELK GROVE VILLAGE, IL, January 23, 2022 - Repeatability in injection molding. Being able to offer this shot after shot means lower cost of operation and consistency. It is key to the production of parts in today’s competitive market and has a crucial influ...

Read moreLooking to Reduce Scrap? Why All-Electric Injection Molding Machines Are the Clear Choice

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving scrap rates in injection molding can have a large impact on increasing profitability. While there are many process improvements for scrap rate reduction, it is also important to consider the type of machi...

Read moreFaster Cycle Times with All-Electric Injection Molding

ELK GROVE VILLAGE, IL, January 6, 2022 - Considering changing out from hydraulic to all-electric machines in the new year, but trying to justify the change? Look no further than the improvements these machines can make to your cycle time. Being able to red...

Read moreHow Automatic Load Cell Calibration Helps Prevent Molding Defects

ELK GROVE VILLAGE, IL, December 29, 2021 - One of the key advantages of all-electric injection molding machines is the ability to monitor actual plastic pressure during injection via a load cell behind the screw, without the need for in-mold transducers. ...

Read moreHow the I/O Checker Minimizes Machine Downtime for Injection Molders

ELK GROVE VILLAGE, IL, December 21, 2021 - Creating injection molded parts not only requires a high level of technical expertise, but also attention to detail. One small mistake can slow down, or even stop production.How many times this year have machine d...

Read moreHow the Mold Guide Makes Set-Up Simple and Efficient

ELK GROVE VILLAGE, IL, December 16, 2021 - Installing a mold in an injection molding machine is a routine process. However, even when tasks are routine, mistakes can be made. Being able to perfect mold change-overs and lessen mistakes can not only help imp...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools