Looking into Hard Turning VTL’s? Read This First.

ELK GROVE VILLAGE, IL, January 5, 2021

Lowering cost, delivering higher quality, and improved speed are three things manufacturers are continually seeking to improve. Hard turning is an essential process because it can help achieve all of these things when done correctly and with the right machine.

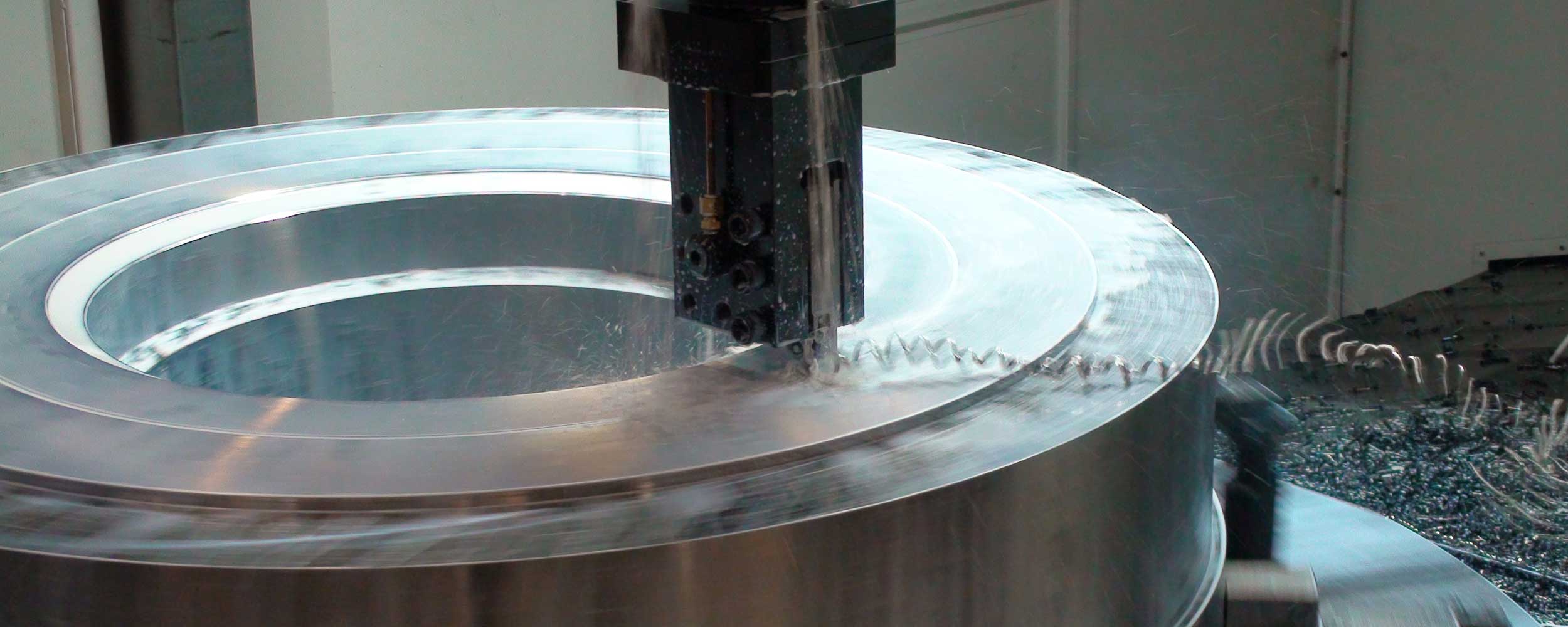

Hard turning technology is defined as using a rigid turning machine for the finish machining operation on hardened steel 55 HRC or greater by utilizing advanced cutting tools. The process can be considered for most pre-grind applications and is considered ideal for workpieces with complex shapes, as all operations can often be completed in one part clamping. It is technology-driven and requires certain performance features and functionalities to the machine tool, process, and tooling.

How to Achieve Successful Hard Turning

Hard turning has measurable benefits you can use to gauge your success. The success is largely measured by the construction and design of the machine, along with the workholding and tool holding. Several important factors to consider when looking to achieve success in hard turning are:

- Machine rigidity

- Workholding Rigidity

- Good vibration damping characteristics

- Rigid tool location

- Component part rigidity

- Rigid cutting tools and advanced insert materials

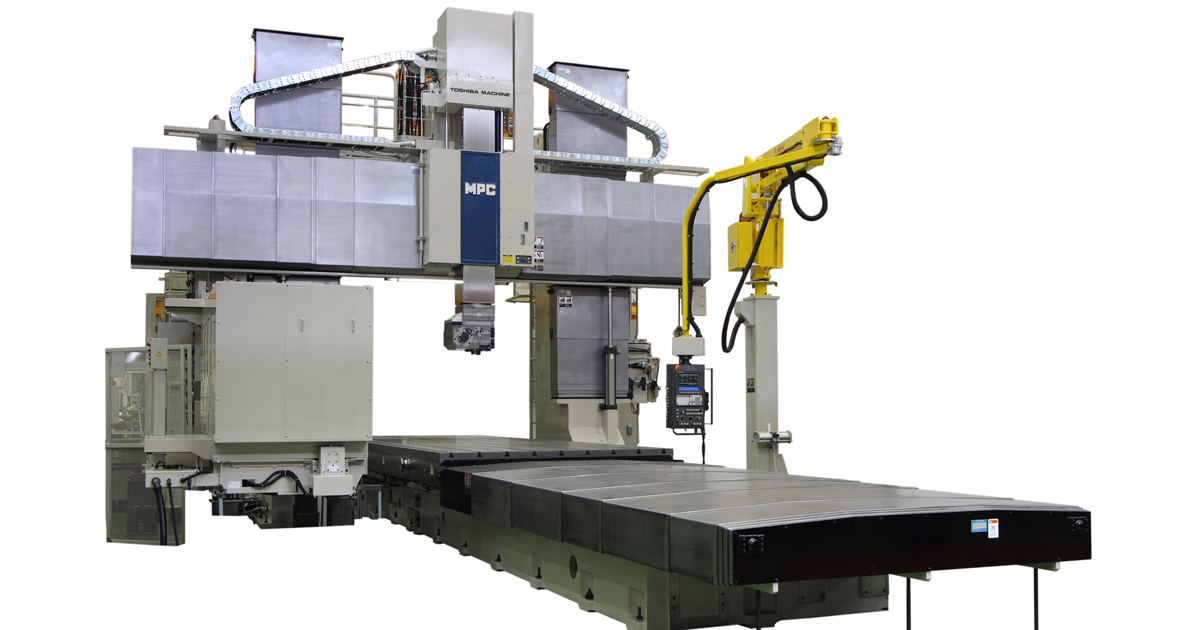

Shibaura Machine builds a full range of Vertical Turning Machines (VTL) for demanding turning applications in the machining of hardened steel materials. Shibaura’s VTL’s are rigid machines that align very well with the requirements for a successful hard turning machine application.

Benefits of Hard Turning

With the right machine, workholding, and tool holding you will see the numerous benefits of hard turning. Industries ranging from automotive, aerospace, bearing, oil/gas, and more have reported production increases and workpiece cost reductions by utilizing Shibaura Machine for their demanding hard turning applications.

The top four reported benefits of hard turning are:

- Lower Price. Lathes are generally less expensive to purchase than grinding machines. They often also require less support equipment and operation time. This adds up to greater productivity, production control, shorter throughput, and increased profits.

- Lathes can handle small lots and complex shapes efficiently. Complex contours can be done with ease.

- Multiple operations can be performed with one set-up and you can “soft turn” and hard turn on the same machine tool. This results in less part handling and opportunity for part damage.

- Improved Waste Management. Lathe’s produce chips that are less expensive to dispose of than swarf’s produced by grinding machines.

Hard turning applications with Shibaura Machines Vertical Turning Lathes deliver significant workpiece processing improvements. Manufacturers have a lower capital investment cost, improved workpiece surface finish, and cost reductions versus using highly specialized and expensive grinding machines.

Related Articles View All Machine Tools Articles

How Does Your Business Benefit From Machine Tool Automation?

ELK GROVE VILLAGE, IL, December 28, 2020 Is it time to consider machine automation?Continually improving quality, efficiency, and productivity in manufacturing are constants. If you are starting to see challenges in any of these areas or experiencing a ne...

Read moreAre You Getting World Class Design From Your Machine Tool Manufacturer?

ELK GROVE VILLAGE, IL, December 21, 2020 People throw out a lot of words when marketing these days. It’s hard to sift through fact or fiction. When a manufacturer states they offer world class design of their machine tools, what exactly should you be look...

Read moreEngineering Your Competitive Advantage

ELK GROVE VILLAGE, IL, December 15, 2020 Application expertise is a vital component of successful machine solutions. When you select the right machine tool paired with the right application processes you’ll be positioning your business for greater success...

Read moreHigh performance Double Column/Bridge/Gantry type Machining Center

Shibaura Machine has been building precision Double Column/Bridge/Gantry type Machines for over 50 years in the most demanding applications in precision tooling for automotive stamping die, injection mold and die cast. We have also offered many solutions ...

Read moreBefore Investing in Your Next Machine Tool Read This First

ELK GROVE VILLAGE, IL, December 8, 2020 High-performing, durable machine tools can make the difference between a job done well and on time and a job, well, not.Investing in machine tools made with quality parts and materials allows those on the job to pow...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools