Does Your Machine Tool Offer True Auxiliary Equipment integration? Why It’s important.

ELK GROVE VILLAGE, IL, February 23, 2021

At the end of the day, machine tools are meant to help people make things. In today’s challenging economic climate many of us are looking to make things quicker, with less energy, and hurdles. Accomplishing this means moving away from a “disconnected” manufacturing floor. Machine tools with integrated auxiliary equipment will not only simplify your machine process, but improve accuracy, reduce human error, and more.

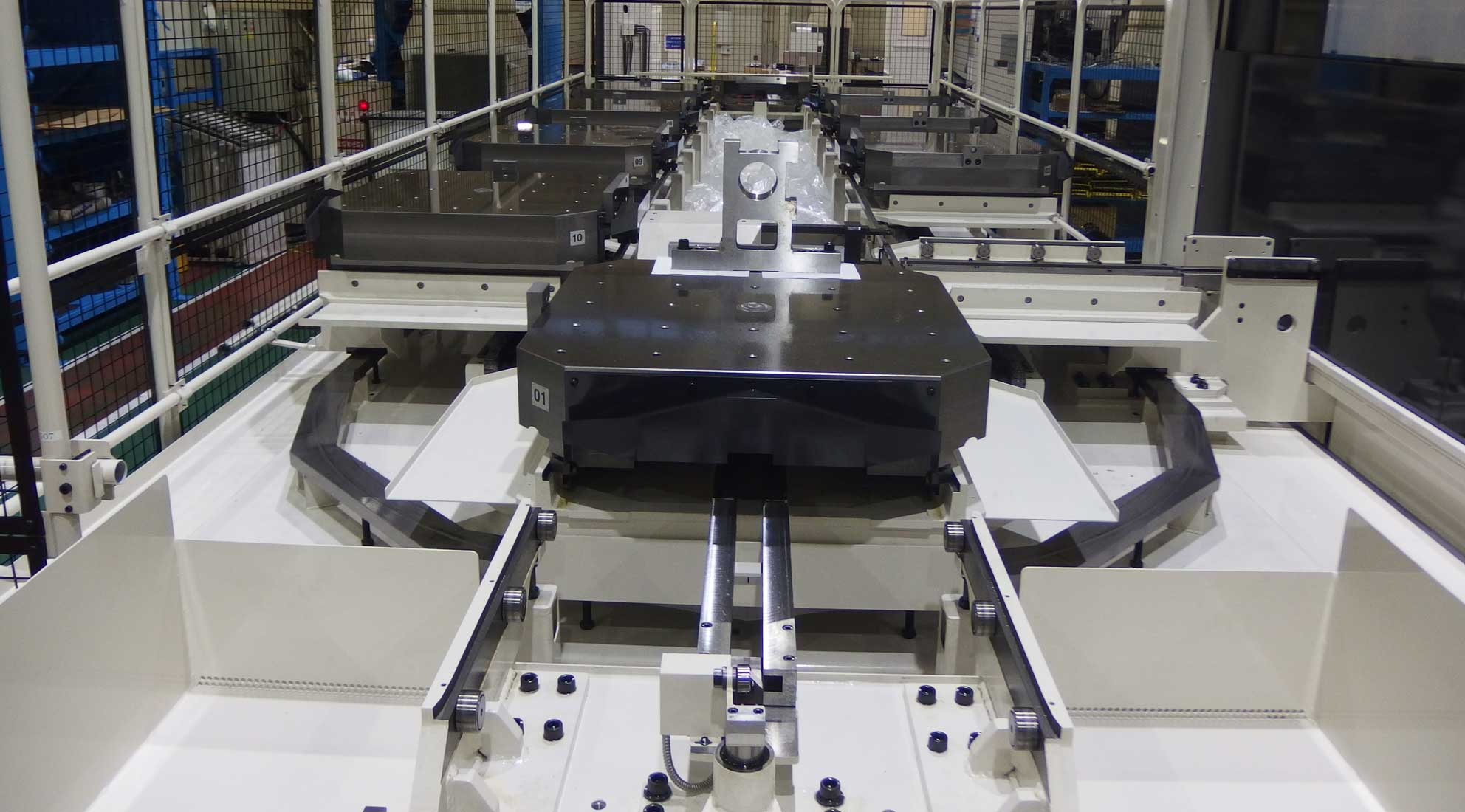

Having a machine that is capable of seamlessly integrating your auxiliary equipment doesn’t have to mean added complexity. Shibaura Machine has designed our CNC machine tools with the option to integrate auxiliary equipment to accomplish just the opposite. With a thoughtful approach to the design, our engineers recognized the auxiliary equipment into an embedded subassembly that is built into the machine tool. This allows our customers a truly integrated, multitasking machine approach versus a series of separate isolated subassemblies.

The Importance of Integrated Auxiliary Equipment

Auxiliary equipment providers not only help manufacturers solve problems, but also explore new productivity ideas to keep your machine tool running as efficiently as possible.

Operational Performance

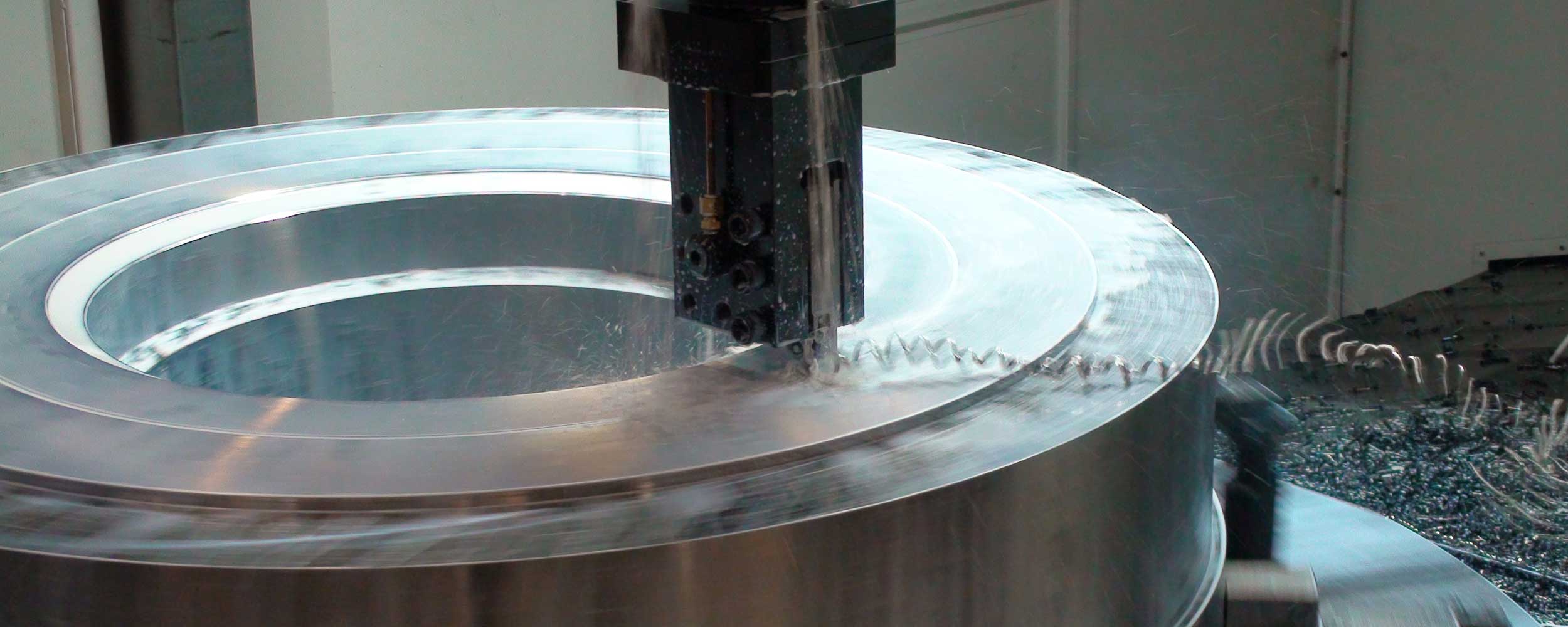

The demand for high-performance, precise, flexible machine tools continues to grow. Auxiliary equipment integration allows your manufacturing operations to keep up with customer requirements whether it is in the semiconductor, energy, gas & oil, aerospace, and automobile industries. With our approach to integrated auxiliary equipment as embedded subassemblies, you have the ability to quickly address complex machining challenges.

Subassembly Connectivity

Shibaura Machine started with a foundation of a repeatable CNC machining process and then integrated secondary equipment to increase productivity and flexibility. This type of subassembly connectivity means true integration, not various pieces of auxiliary equipment running disparate. This connectivity gives increased visibility into your operations, improving production.

Operational Safety

Integrating auxiliary equipment offers improved machine power and reduced manpower. Users are able to work directly with the Shibaura’s machine tool controller to see that all auxiliaries are connected to the machine and are correctly configured to run the job. This allows a safer, more accurate, and error-proof method.

Our CNC machine tools offer manufacturers a complete solution. Contact our experts to learn more about the connectivity capabilities offered in our CNC machine tools.

Contact us to see how auxiliary equipment integration helps your operations!

Related Articles View All Machine Tools Articles

How a Tool Probing System Impacts Your Manufacturing Performance and Profitability

ELK GROVE VILLAGE, IL, February 17, 2021 Have you ever heard the saying time is the most valuable commodity? On the factory floor that couldn’t be more true, time is indeed money. In order to make the best use of time, many manufacturers are continually l...

Read moreMaking Complex Simplified with Shibaura Machine CNC Machine Tools

ELK GROVE VILLAGE, IL, February 9, 2021 Simple operator controls and easy to use machines have become essential on shop floors in order to stay competitive. All around ease of use helps manufacturing operations set up jobs faster and even more accurately,...

Read moreHow Quick Change Tooling Can Boost Profits in 2021

ELK GROVE VILLAGE, IL, January 18, 2021 Tool changes in machine operations can take time. But what if you could shave just a few seconds, imagine even minutes off of this process? In a large volume machine operation, this could add up to hundreds of thous...

Read moreLooking into Hard Turning VTL’s? Read This First.

ELK GROVE VILLAGE, IL, January 5, 2021 Lowering cost, delivering higher quality, and improved speed are three things manufacturers are continually seeking to improve. Hard turning is an essential process because it can help achieve all of these things whe...

Read morePut Your Machine Tool Investment to Work

ELK GROVE VILLAGE, IL, January 26, 2021 Investing in quality machine tools allows operators to power through their shift uninterrupted and with the necessary precision. And while Shibaura Machine Company, America’s high precision and high-performance mach...

Read moreEngineering Your Competitive Advantage

ELK GROVE VILLAGE, IL, December 15, 2020 Application expertise is a vital component of successful machine solutions. When you select the right machine tool paired with the right application processes you’ll be positioning your business for greater success...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools