Shibaura Machine’s Vertical Turning Lathes Line Up: Strong, Rigid, and Flexible

ELK GROVE VILLAGE, IL, May 10, 2021

The advantages and possibilities of vertical turning lathes (VTLs) are enormous. While their counterparts the horizontal lathes might be better known, the VTL has evolved to become a powerhouse. Incorporating not only many of the productive technology innovations we enjoy with the horizontal turning centers, but the added benefit of a smaller footprint due to its upright nature makes them a machine to truly consider.

The Benefits of Turning Machining Upright

By standing the lathe on a vertical plane, the design provides shops a variety of production and cost benefits. A smaller footprint means more space for more machines, the upright nature offers 360° accessibility. You’ll also get the added benefit of additional stability due to the force of gravity which is particularly useful when cutting a variety of parts from industries such as aerospace, oil & gas, construction & mining, automotive, energy, space & defense and more.

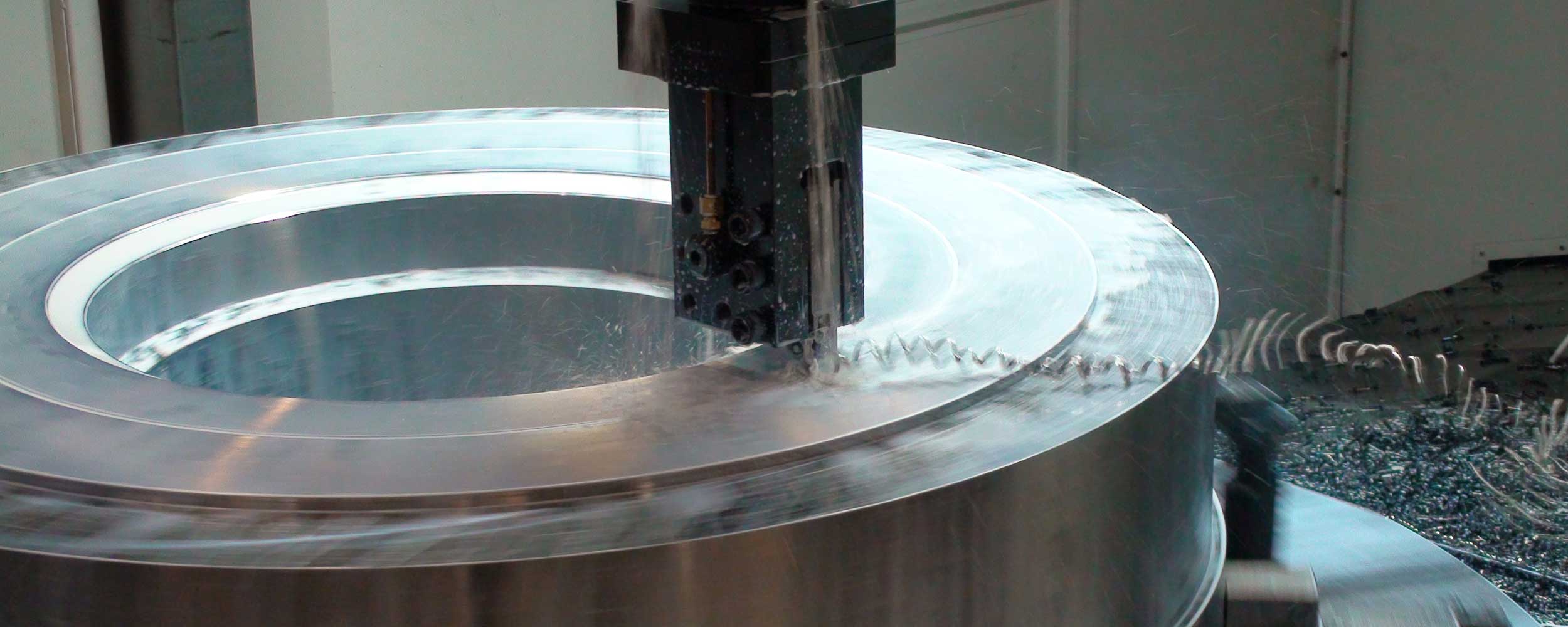

These ram-type machines have gotten the reputation for heavy-duty, high power cutting of large parts. However, don’t count them out for other machining techniques and capabilities. They are equipped to cover a wide range of applications, allowing roughing or finishing of workpieces requiring both turning and milling processes. Fragile work pieces requiring low clamping pressures may also benefit from the vertical turning process with a purpose built clamping system. Bottom line, these machines can be extremely versatile and a highly productive addition to any shop floor.

The Difference in Shibaura Machine’s Vertical Turning Lathes

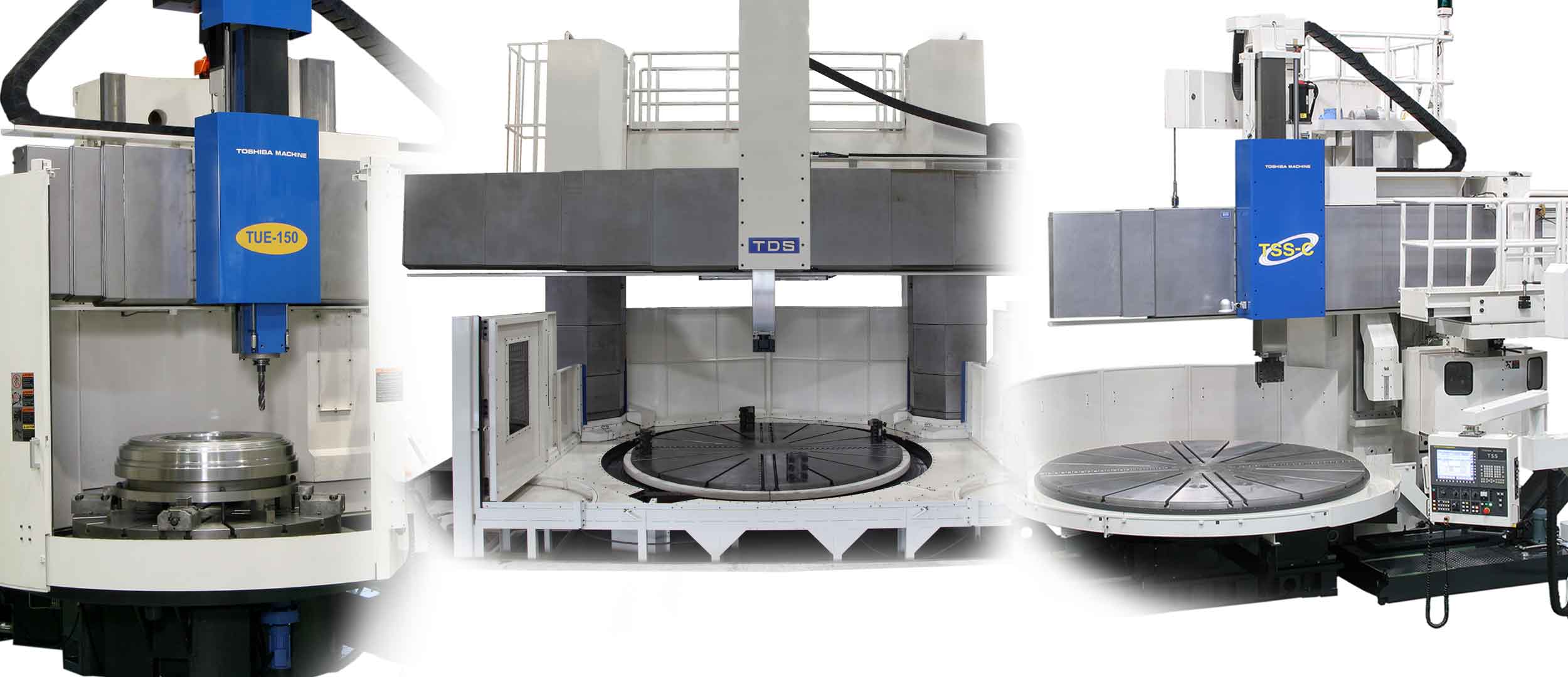

As a leader in manufacturing precision machine tools, Shibaura Machine offers one of the most complete lines of RAM style Vertical Turning Mill Lathes in the industry. From a 40 inch diameter table machine up to a double column turn mill machine with tables as large as 26 feet in diameter these VTL’s are designed strong, rigid and flexible.

6 different models of Vertical Turning Lathe Machines Available:

- TUE series with and without live spindle

- TUD series heavy duty conventional turning machine

- TMD series heavy duty live spindle

- TDS series heavy duty large size live spindle

- TSS series large envelope workzone machine

- TD series mother machine with a table up to 26 feet in diameter

All of the major cast iron components of our VTL’s are poured right at our foundry in Japan to ensure quality control throughout the manufacturing process.

Additional features and options on our product line include:

- Adjustable crossrail

- Live spindle RAM

- Automatic tool changers

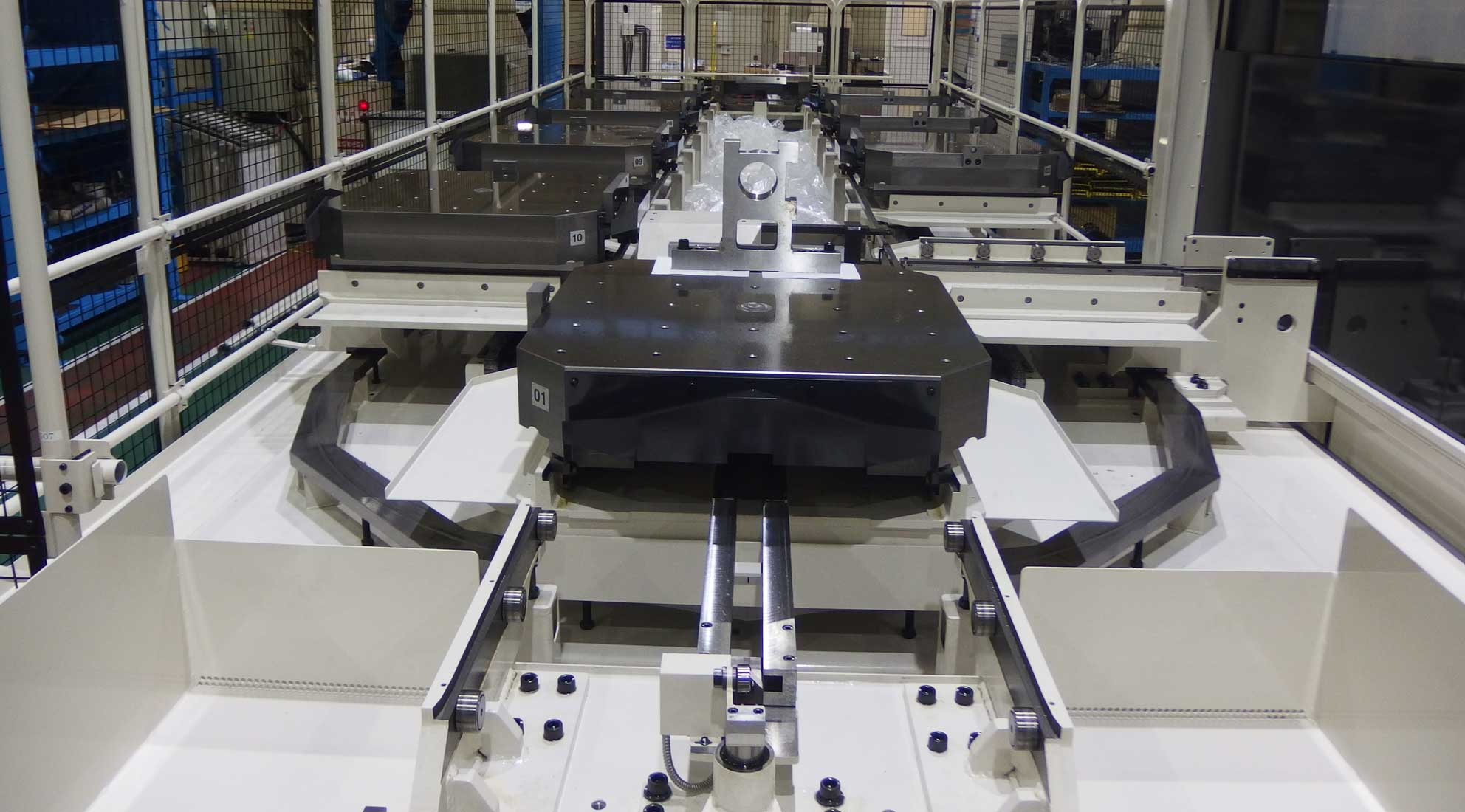

- Automatic pallet changers

- Full chip enclosure

- Workpiece probe system

- Tool verification and tool length and diameter setting probe

- Quick change tooling options

- Innovative chip management options

- Fanuc CNC control

- Highly accurate C axes turning/milling tables

Shibaura Machine Company, America has the experience that you need to make the best decision for your manufacturing organization when it comes to Vertical Turning Machine Tools. To receive assistance in evaluating machines please contact our CNC machining experts.

Contact our machine tool team to learn more about our entire line of solutions.

Related Articles View All

Looking into Hard Turning VTL’s? Read This First.

ELK GROVE VILLAGE, IL, January 5, 2021 Lowering cost, delivering higher quality, and improved speed are three things manufacturers are continually seeking to improve. Hard turning is an essential process because it can help achieve all of these things whe...

Read moreHow Quick Change Tooling Can Boost Profits in 2021

ELK GROVE VILLAGE, IL, January 18, 2021 Tool changes in machine operations can take time. But what if you could shave just a few seconds, imagine even minutes off of this process? In a large volume machine operation, this could add up to hundreds of thous...

Read moreHow a Tool Probing System Impacts Your Manufacturing Performance and Profitability

ELK GROVE VILLAGE, IL, February 17, 2021 Have you ever heard the saying time is the most valuable commodity? On the factory floor that couldn’t be more true, time is indeed money. In order to make the best use of time, many manufacturers are continually l...

Read moreAre You Getting World Class Design From Your Machine Tool Manufacturer?

ELK GROVE VILLAGE, IL, December 21, 2020 People throw out a lot of words when marketing these days. It’s hard to sift through fact or fiction. When a manufacturer states they offer world class design of their machine tools, what exactly should you be look...

Read moreDoes Your Machine Tool Offer True Auxiliary Equipment integration? Why It’s important.

ELK GROVE VILLAGE, IL, February 23, 2021 At the end of the day, machine tools are meant to help people make things. In today’s challenging economic climate many of us are looking to make things quicker, with less energy, and hurdles. Accomplishing this me...

Read moreMachine Tool Partnerships Built to Fuel Customer Growth

ELK GROVE VILLAGE, IL, March 16, 2021 Remember the old saying, “two heads are better than oneYou can’t become a leader in any industry without a foundation of good people and partnerships to help fuel your growth. Partnerships allow you to come together t...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools