Critical Factors to Consider With Your Machine Tool Foundation

ELK GROVE VILLAGE, IL, February 15, 2023 -

Machine tools are the backbone of the modern manufacturing industry and play a critical role in the production of goods and services. While the machine tools themselves are the main focus, their foundation is a crucial component that is often overlooked. A sturdy foundation is essential for the proper functioning of these machines, and without it, their operation can be hindered.

Many shops don’t realize that the performance of machine tools can vary greatly based on the foundation's shape, structure, and materials used. Your foundation ultimately helps reduce external factors' influence (e.g. forklifts, presses, etc.), improve accuracy, extend the life of the machine, and make the work environment safer. Investing in a well-designed foundation for machine tools is a wise investment, as it will ensure the smooth operation of the machines and the production of high-quality products.

Creating a Foundation to Last

When designing a machine tool foundation, there are several key factors that a factory should consider to ensure that the foundation is appropriate for the specific machine tool and application. Some of these factors include:

Machine Tool Weight and Height

The weight of the machine tool is an important factor to consider when designing its foundation because it directly affects the stability and accuracy of the machine. The foundation must be able to support the weight of the machine and any additional loads it generates during operation, such as cutting forces, to ensure that it remains stable and does not vibrate excessively.

The table height also needs to be considered. To set up the workpiece, a pit is often necessary, and it's crucial to consider the factory height and ensure sufficient space for smooth operation.

Foundation Design Characteristics

The foundation should be designed to match the specific vibration characteristics of the machine tool to ensure that it operates smoothly and accurately. This is especially important for high-speed machines to improve stability and accuracy.

Environmental Factors

The foundation should be able to withstand changes in temperature, humidity, and other environmental conditions that could affect the machine's performance.

Foundational Influences

The type of floor the machine tool will be installed on is also an important factor to consider when choosing a foundation. Concrete is the most commonly used material for building foundations. However, the thickness of the concrete and the distribution of cement also play a significant role in determining the foundation's strength, which is usually indicated by the ground pressure resistance. When a machine operates, a load is applied in the direction of movement, generating inertia. This means that the ground pressure resistance must be calculated considering more resistance than just the weight of the machine.

Maintenance Access

The foundation should be designed to provide easy access for maintenance and repairs. The foundation should also allow for the removal and installation of the machine tool with minimal difficulty.

Cost

The foundation should be designed to meet the specific requirements of the machine tool and the factory, but should also be cost-effective to ensure that the investment is a good one.

Set Your Machine Tool Up For Success

Shibaura Machine offers a variety of machine tools, including horizontal boring machines, vertical lathes, and gantry machines. With a focus on improving work environments, our team aims to find a foundation that best suits your factory layout and enhances work efficiency.

For more information on the basics of machine foundations, please consult the Machine Tool team.

Related Articles View All Machine Tools Articles

Polar Coordinate Interpolation: Unlocking New Possibilities with Shibaura Machine Tools

ELK GROVE VILLAGE, IL, February 7, 2023 - Have you ever felt like your machining operations were stuck in a straight line? Polar Coordinate Interpolation may be the answer you've been searching for. With this motion control method, you can upgrade your mac...

Read moreMaking Sense of Machine Tool Thread Milling for Your Application

ELK GROVE VILLAGE, IL, January 30, 2023 - When it comes to adding threads to a workpiece, the choice of method can make a significant difference to the outcome. For parts made from difficult-to-machine materials, thread mills have become an increasingly po...

Read moreSupporting Success: Shibaura Machine Tools' Growing Commitment to Customers

ELK GROVE VILLAGE, IL, January 25, 2023 - When purchasing a machine tool from Shibaura Machine, you can expect high-performing equipment. Customer satisfaction is our top priority, and we go above and beyond to ensure that our customers receive the best se...

Read moreFind Your Ideal Chip Conveyor Set Up

ELK GROVE VILLAGE, IL, January 10, 2023 - One way manufacturers can work to maximize machine tool output is with the use of a chip conveyor. Not only does it keep the workspace clean and clear of chips, but makes it easier for operators to access the machi...

Read moreGet the Most Out of Your TOSNUC 999 CNC Controller

ELK GROVE VILLAGE, IL, January 04, 2023 - Going into 2023 are you taking advantage of everything your CNC control can do for you? The TOSNUC 999 provides plenty of manufacturing advantages with its user-friendly interface and functions. Designed with the m...

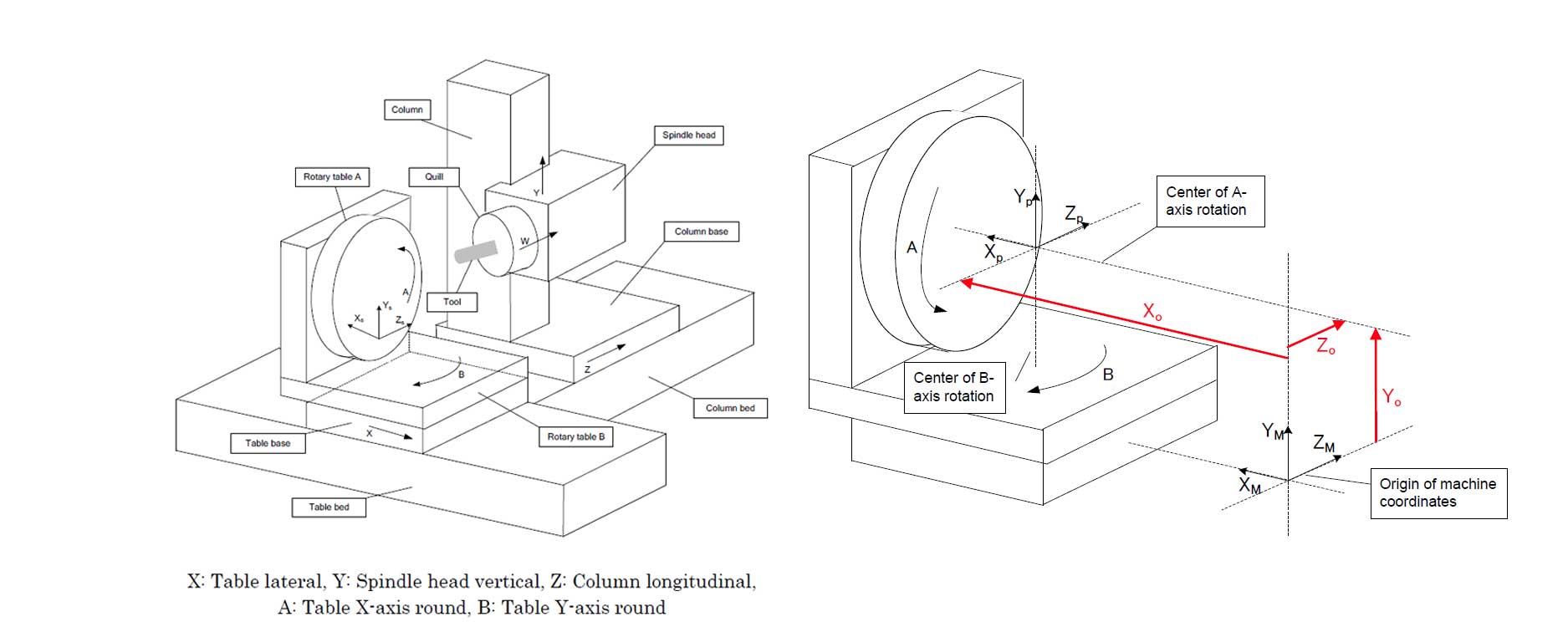

Read moreExpand your Horizontal Boring Machine Capabilities with Additional Axis Control

ELK GROVE VILLAGE, IL, December 14, 2022 - Depending on a parts’ geometry, having 5-axis machining can have a major impact on your productivity and quality. Being able to move the cutting tool along five axes allows for a high degree of flexibility and pre...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools