How Injection Molding Training Maximizes Your Machine ROI

ELK GROVE VILLAGE, IL, April 1, 2021 – Having a comprehensive understanding of your injection molding machine will not only improve your production processes, but overall profitability.

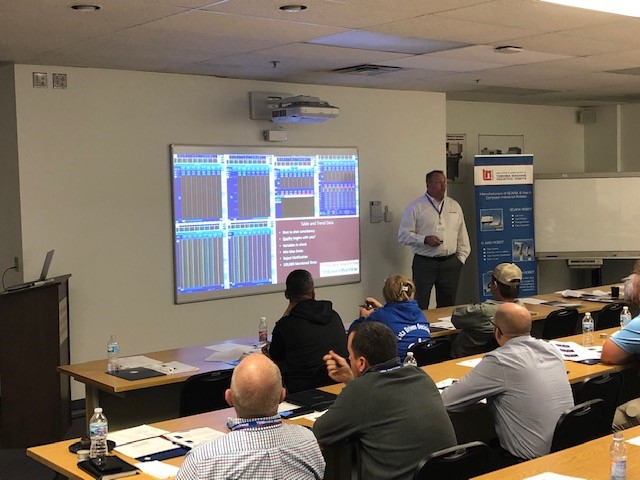

Setting this type of foundation is not only a smart investment in your machine, but also your team- creating a path for success in the industry. Shibaura Machine recognizes how valuable this is and that is why we offer both virtual and hands-on classroom training options to fulfill your company’s specific needs. With our certified instructors covering everything from controls, processing, and maintenance your operators will have the required skills to not only operate the machine with confidence, but convey the same overall knowledge base- making your company the expert.

Training to Maximize Investments & Improve Business

Shibaura Machine instructors deliver updated and valuable industry and machine information, as well as best practices and tricks to improve job performance. The goal of the training program is to make it as easy to understand as possible, so your team can immediately put what they learned into action in order to improve overall profitability.

Current Injection Molding Training Courses

Our courses focus on Shibaura Machine injection molding equipment and can be customized to your needs.

- V50 Controller: Basic understanding of machine capabilities, highlighting the features of the V50 Controller- including general and sub screens.

- V70 Controller: Basic understanding of ECSXIII machine capabilities, highlighting the features of the V70 Controller- including general and sub screens.

- Maintenance - Electric and Hydraulic Machines: Comprehensive review of proper maintenance procedures for Shibaura electric or hydraulic molding machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented, along with hands-on practice.

- Molding 360 Comprehensive Processing: This is an intensive, 3-day injection molding processing course designed to enhance skills and provide the tools required to maximize quality, productivity, and profitability. Students will be taught to develop a process through use of scientific molding concepts. Classroom learning is combined with hands-on learning at the machine. This is an advanced level course and students are expected to already have a basic understanding of the injection molding process.

Shibaura Machine Customers can Schedule Training

Continual high quality training is key to improving your overall profitability.

Our training facilities are located at our tech centers in Elk Grove Village, Illinois, Ontario, California, Charlotte, North Carolina, and Markham, ON, Canada. Due to COVID-19 we have temporarily suspended our tech center training. We can currently work with customers to offer virtual training options or classes held in-person at their facility. Also watch for webinars which will become available later this spring.

Shibaura Machine customers can contact our injection molding team below to request training information!

Training for Shibaura Machine Customers

Related Articles View All Articles

Three-Stage Mold Protection Saves Time and Money

ELK GROVE VILLAGE, IL, March 24, 2021 – Mold protection often goes overlooked, but mold damage and downtime can be prevented by utilizing this feature properly. Each mold has its own requirements, so having a machine that makes input and monitoring easy is...

Read moreComparing Injection Molding Ejector Systems - All-Electric vs. Hydraulic

ELK GROVE VILLAGE, IL, March 17, 2021 – Hearing the manufacturing line is down and a mold has been damaged because of an ejector issue is the last thing an operations manager wants to hear. Unfortunately, if you can’t maintain tight control over how and wh...

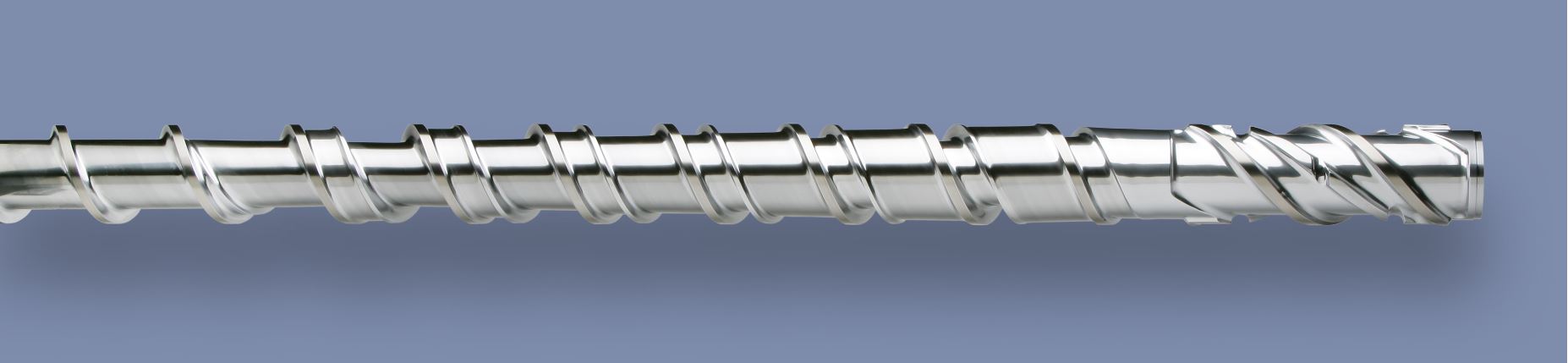

Read moreWhy Screw Design is Critical to Your Injection Molding Success

ELK GROVE VILLAGE, IL, March 9, 2021 – The proper selection of your screw for any given injection molding application is critical to successful processing. In fact, changing to an optimized screw design has been shown to improve cycle times and reduce part...

Read moreWhat to Know When Deciding Between All-Electric and Servo-Hydraulic Injection Molding Machines

ELK GROVE VILLAGE, IL, March 2, 2021 – Precision and repeatability. These are two things that all shop floors are looking to continually achieve. When considering what type of injection molding machine you want to help you achieve these things there are se...

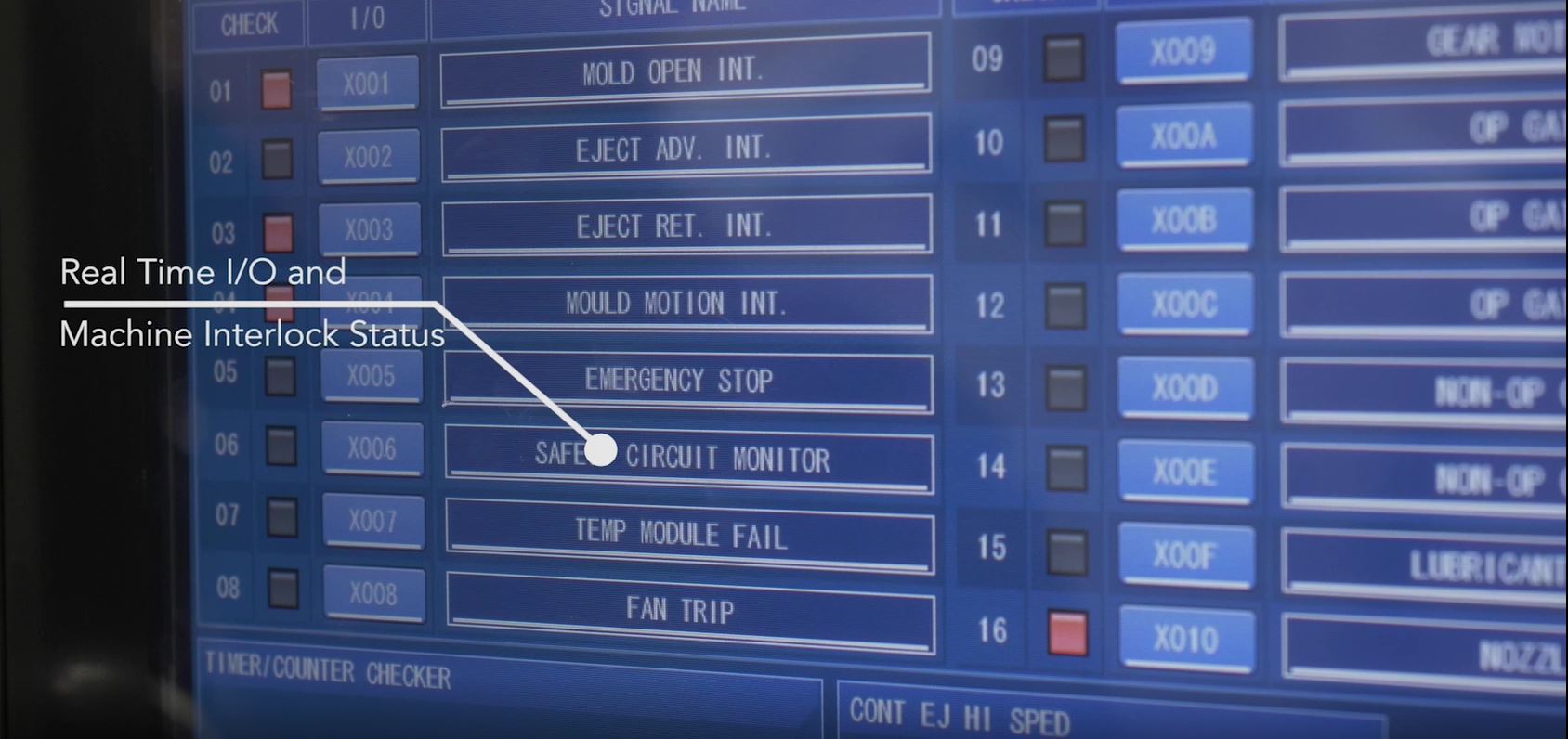

Read moreDoes Your Injection Molding Machine Offer Easy Visibility into Diagnostics and History?

ELK GROVE VILLAGE, IL, February 23, 2021 – Troubleshooting and maintenance can become tedious and time-consuming tasks on the manufacturing floor. What would it mean to your business if you were able to more efficiently understand your machine and have qui...

Read moreWhy Injection Molding Machine Design Matters - And What to Look For

ELK GROVE VILLAGE, IL, February 19, 2021 – When you have a well-designed injection molding machine there are no limits to what types of molded parts you can create. Whether it's automotive, packaging, medical, or custom plastics - an injection molding mach...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools