Why Injection Molding Machine Design Matters - And What to Look For

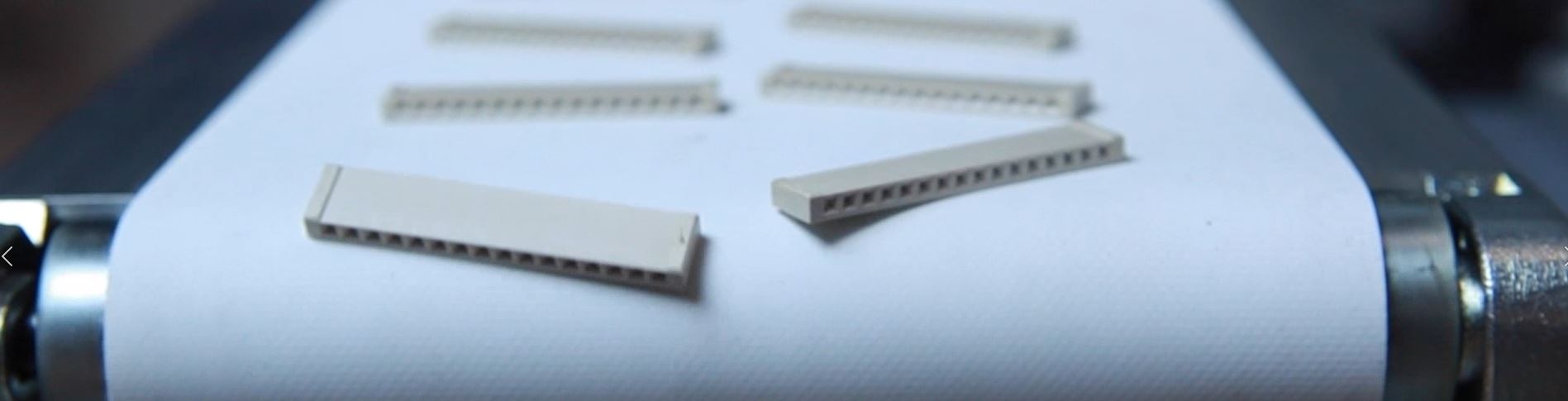

ELK GROVE VILLAGE, IL, February 19, 2021 – When you have a well-designed injection molding machine there are no limits to what types of molded parts you can create. Whether it's automotive, packaging, medical, or custom plastics - an injection molding machine that allows you to reduce production costs, is easy to use, and high performance makes a difference.

Shibaura has designed the ECSXIII all-electric machine with our customers in mind. The construction of our injection molding machine sets new design standards in terms of precision, energy efficiency, performance, and cleanliness.

Designed With Your Company in Mind

When thinking about the design of an injection molding machine, we wanted to get inside the head of the user while considering the overall goals of the company. How can we make a user’s job safer, allow them to be more efficient, all while improving quality, speed, and cleanliness? It largely comes down to automation and machine ease of use.

Several features of the ECSXIII all-electric machine that stand out:

- Dual hydraulic core pull program & electrical interface comes standard and portable “plug and play” hydraulic power units are also available

- Bushing free, grease-free tie bars to lower contamination of molded parts

- Advanced load cell for injection ensures accurate control of the plastic injection pressure and when combined with the V70 controller this load cell can help achieve scientific molding over the balance of mold without the use of internal transducers

- Dual air blow to help with ejecting difficult parts

- 5-point Linkline toggle mechanism which offers even force distribution, extended mold life, and reduced maintenance

Machine Ease of Use Improves Overall Efficiency

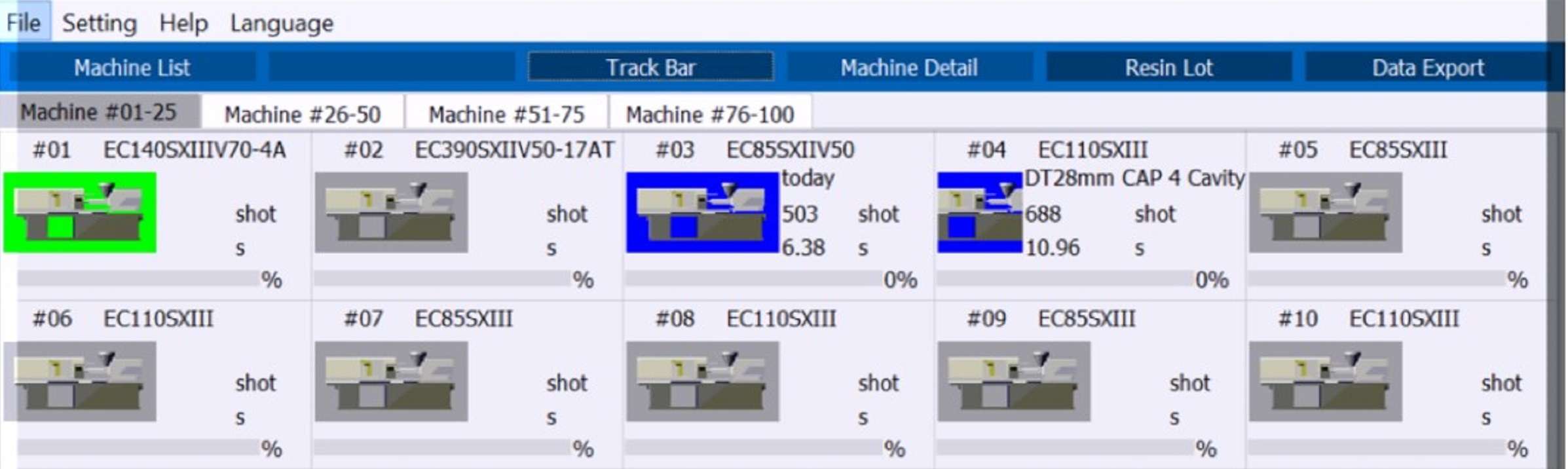

The efficiency of the injection molding machine is showcased by several key features that make it easier to use. First, the V70 controller is designed with the “smart factory” in mind, one that is capable of integrating with auxiliary equipment via OPC-UA communication. The V70 split-screen controller allows the user to speed up mold setups, optimize cycle times, analyze part defects, troubleshoot molding defects, and more with an intuitive interface. The machine also features durable linear guides to ensure accurate injection speed and backpressure control, ensuring shot-to-shot repeatability over the life of the machine. Lastly, the Euromap 67 (50 pin) robot interface receptacle comes standard for connecting a “handling device” (the Euromap 12 (32 pin) is also available). All of these features allow you a faster payback on your machinery investment by allowing the user to be more confident in their job and able to work more efficiently.

When it comes to being able to monitor and make changes quickly, the ECSXIII has also been designed to make it easy for the user. For example, the standard heater band failure alarm means the user can quickly identify a failed heater band and immediately replace it- no need to test each band in the zone. Also, the auto tonnage adjustment via strain gauge on the tie bar allows for real-time tonnage monitoring and on-the-fly adjustment to ensure it is accurate at all times.

No matter what application you have, Shibaura Machine prides itself on our high-performance machines for reliable, economical, and efficient production. Contact our team of experts to learn more about the design benefits of the ECSXIII all-electric machine.

Contact us today to learn how the design our our SXIII Series can benefit your operation!

Related Articles View All Articles

Minimizing Injection Molding Complexity without Compromising Capability

ELK GROVE VILLAGE, IL, February 10, 2021 – The convenience of your injection molding machine controller correlates directly with your factory production efficiency. A controller that is not only powerful but offers intuitive operation, simple navigation, ...

Read moreAll-Electric Injection Molding Machines Offer More Than Energy Savings

ELK GROVE VILLAGE, IL, February 3, 2021 – Did you know energy spending in most injection molding plants is one of the highest costs month after month? At the end of the day, it is often costing more to run old machines then it would to invest in new, energ...

Read moreImprove Quality Control and Productivity with the iPAQET Remote Data Management System

ELK GROVE VILLAGE, IL, January 27, 2021 – Not all monitoring and data management systems are created equal. Many systems are prone to errors, have less than easy to use interfaces, or require someone to be in front of the machine- oftentimes collecting dat...

Read moreHow to Minimize Injection Molding Machine Downtime

ELK GROVE VILLAGE, IL, January 19, 2021 – Whether planned or unplanned, machine downtime is very costly. Aside from directly impacting production and labor, machine downtime extends to other areas of operation and can affect the organization as a whole. An...

Read moreReducing Reject Rates for Injection Molding is Within Reach

ELK GROVE VILLAGE, IL, January 13, 2021 – If parts are considered defective they are likely getting rejected by customers. That means the cost lands on you, but with a premium because you have equipment and labor costs tied into it. Luckily, the right inje...

Read moreReducing Injection Molding Cycle Times Using All-Electric Technology

ELK GROVE VILLAGE, IL, January 5, 2021 – When it comes to improving manufacturing processes, optimizing the parameters of your injection molding machine is critical. Specifically, working to reduce cycle times in injection molding can allow you to produce ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools