Services to Keep Your Injection Molding Machines Running Efficiently

ELK GROVE VILLAGE, IL, April 14, 2021 – High quality parts come from high quality machinery.

In order to keep your injection molding machines running efficiently with minimal downtime it's important to have the backing of a strong service team. Most molding shops consider their injection molding machines some of their biggest investments, which is why Shibaura Machine has created a comprehensive service offering to help maximize machine output for our customers.

With over 47 years in the USA and more than 10,000 injection molding machines installed in North America, we have built a high quality service offering to support these customers. Our services allow customers to optimize their machines, getting the most out of their investment. From support over the phone and on-site, to a variety of upgrade solutions to give added value, and training opportunities that increase your teams competencies- these diverse services allow customers to get the best performance from their Shibaura injection molding machines.

Qualified and Close Support

Bottom line, downtime costs money. When it comes to servicing an injection molding machine it is vital you have a qualified and close support system to ensure your machine investment won’t let you down.

Shibaura Machine has five strategically placed service offices and 28 service technicians located throughout North America to ensure support is never far away. We also offer full time phone support to answer urgent questions and keep you up and running.

Highlights of our technical and support services include:

- Start-up services that ensure proper installation and on-site operator training

- Field services on call nationwide to connect you with our staff of technical service representatives to perform machine repairs or service at your location

- Phone support which connects you with our technical experts to get answers to urgent questions and problems

- Upgrade and retrofit services that allow your existing machine to be even more cost-effective or utilized for new applications

- Training services that are easy to understand- from individualized on-site programs to seminars at our training centers around North America

Submit a Service Request

Our goal is to provide you easy access to our comprehensive service offerings. Shibaura Machine’s dedicated service personnel puts decades of injection molding expertise at your fingertips. This ensures that together we can help you overcome challenges and discover new growth opportunities. Contact us at (888) 593-1616 or submit an online service request below to learn more about available support options.

Shibaura Machine Injection Molding Service

Related Articles View All Articles

Minimize Injection Molding Downtime with a Good Parts Partner

ELK GROVE VILLAGE, IL, April 8, 2021 – Even with impeccable maintenance, your injection molding machine will find itself needing spare parts at some point. When that time comes, having a machine partner that can get you the correct part easily and efficien...

Read moreHow Injection Molding Training Maximizes Your Machine ROI

ELK GROVE VILLAGE, IL, April 1, 2021 – Having a comprehensive understanding of your injection molding machine will not only improve your production processes, but overall profitability. Setting this type of foundation is not only a smart investment in your...

Read moreThree-Stage Mold Protection Saves Time and Money

ELK GROVE VILLAGE, IL, March 24, 2021 – Mold protection often goes overlooked, but mold damage and downtime can be prevented by utilizing this feature properly. Each mold has its own requirements, so having a machine that makes input and monitoring easy is...

Read moreComparing Injection Molding Ejector Systems - All-Electric vs. Hydraulic

ELK GROVE VILLAGE, IL, March 17, 2021 – Hearing the manufacturing line is down and a mold has been damaged because of an ejector issue is the last thing an operations manager wants to hear. Unfortunately, if you can’t maintain tight control over how and wh...

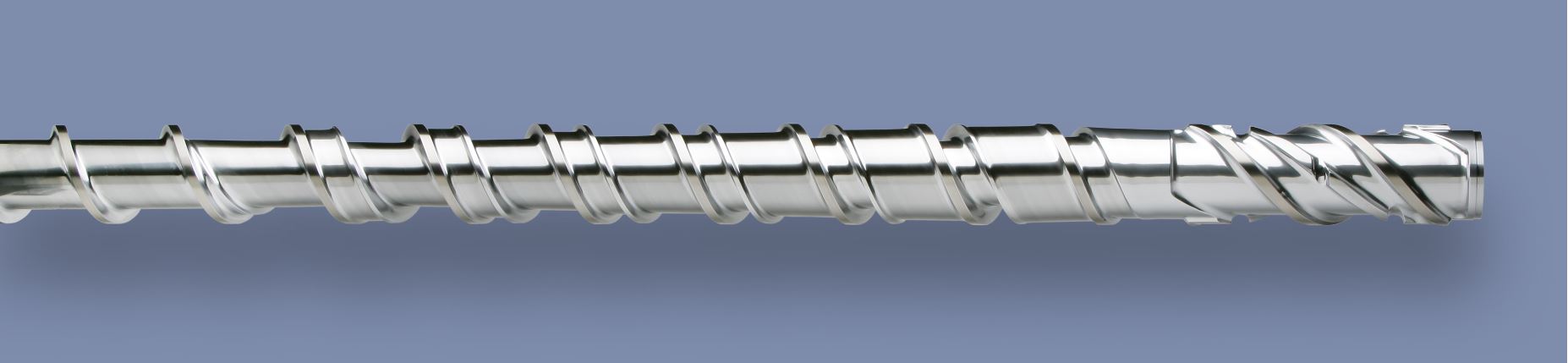

Read moreWhy Screw Design is Critical to Your Injection Molding Success

ELK GROVE VILLAGE, IL, March 9, 2021 – The proper selection of your screw for any given injection molding application is critical to successful processing. In fact, changing to an optimized screw design has been shown to improve cycle times and reduce part...

Read moreWhat to Know When Deciding Between All-Electric and Servo-Hydraulic Injection Molding Machines

ELK GROVE VILLAGE, IL, March 2, 2021 – Precision and repeatability. These are two things that all shop floors are looking to continually achieve. When considering what type of injection molding machine you want to help you achieve these things there are se...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools