Monitor Injection Molding Energy Consumption Easily on the SXIII Series

ELK GROVE VILLAGE, IL, February 16, 2022 - Plastic injection molding machine drive technology has evolved dramatically over the decades. One of the most significant changes is the all-electric servo drive design in comparison to traditional hydraulic machines. The all-electric machine brings improved energy consumption and efficiency, but just how much is the question many manufacturers want to know.

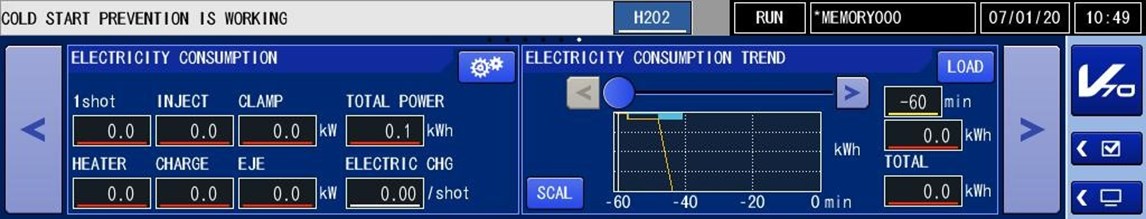

When the electric bill arrives it is based on total demand, peak performance, and power for the entire facility. Shibaura Machine has put the power of knowing the energy consumption for the SXIII all-electric injection molding machine in your hands using the V70 controller’s new Energy Consumption monitoring tool. This function tracks the kWh on the entire machine, specific motors and barrel heaters, while providing the data in user-friendly graphs and charts.

Improve Energy Consumption and Efficiency

Armed with the data from the Energy Consumption monitoring tool on the V70 controller, users are able to take action to further reduce energy consumption and improve efficiency. This tool breaks down power consumption from the injection, clamp, barrel heaters, ejection, and charge. It also allows for users to pull up the average electric power of 1 shot per cycle and the electricity rate in one of the following settings:

- Electricity rate per 1 shot

- Electricity rate per day

- Electricity rate per month

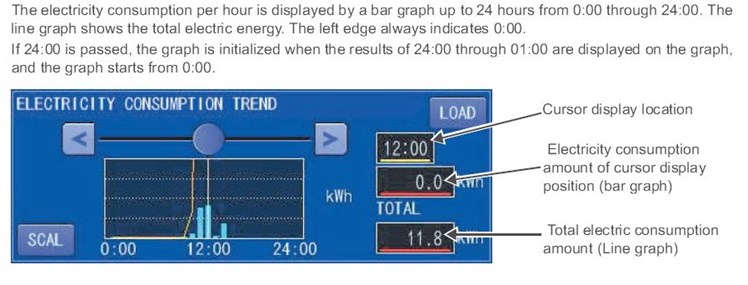

Users can use this monitoring tool to easily see electricity consumption trends over specific periods of time. This is especially helpful to help predict future energy usage based on similar production volumes.

The graph below is showing the electricity consumption amount per minute, up to 60 minutes. Users can also track per day, as well as review daily and monthly details through the past year which can be exported for reporting and monitoring purposes.

Energy use in injection molding is variable and controllable. With the data found in the Energy Consumption monitoring tool users can better understand machine power usage for specific production runs. This insight can help you predict facility energy usage for specific periods of time and aid in creating a more informed energy management process.

Learn More

Contact the Injection Molding Machine team to learn more about the Energy Consumption monitoring tool and all the features on the V70 controller.

Tel: (888) 593-1616

Contact us today to learn more about the energy consumption monitoring tool on the V70 controller!

Want to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools

System Robotics

Related Articles View All Articles

Reduce Cooling Water Load with All-Electric Machines

ELK GROVE VILLAGE, IL, February 2, 2022 - Water cooling systems have long been used in hydraulic injection molding machines in order to keep the machine running smoothly. But imagine being able to reduce cooling water load requirements- it will allow you t...

Read moreImproving OEE with All-Electric Machines

ELK GROVE VILLAGE, IL, January 31, 2022 - Stops in production, whether planned or not, create Availability Loss on the factory floor. While it isn’t always possible to eliminate changeover time, being able to significantly reduce it along with unplanned do...

Read moreWhy Repeatability and All-Electric Molding Machines Go Hand in Hand

ELK GROVE VILLAGE, IL, January 23, 2022 - Repeatability in injection molding. Being able to offer this shot after shot means lower cost of operation and consistency. It is key to the production of parts in today’s competitive market and has a crucial influ...

Read moreLooking to Reduce Scrap? Why All-Electric Injection Molding Machines Are the Clear Choice

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving scrap rates in injection molding can have a large impact on increasing profitability. While there are many process improvements for scrap rate reduction, it is also important to consider the type of machi...

Read moreFaster Cycle Times with All-Electric Injection Molding

ELK GROVE VILLAGE, IL, January 6, 2022 - Considering changing out from hydraulic to all-electric machines in the new year, but trying to justify the change? Look no further than the improvements these machines can make to your cycle time. Being able to red...

Read moreHow Automatic Load Cell Calibration Helps Prevent Molding Defects

ELK GROVE VILLAGE, IL, December 29, 2021 - One of the key advantages of all-electric injection molding machines is the ability to monitor actual plastic pressure during injection via a load cell behind the screw, without the need for in-mold transducers. ...

Read more