Simplify Injection Molding Machine Maintenance with the V70 Controller

ELK GROVE VILLAGE, IL, February 9, 2022 - Performing preventative maintenance is necessary to ensure your injection molding machine longevity and process stability. However, when it comes to tight deadlines and the choice is between machine preventative maintenance and meeting production commitments, most companies will choose the latter. This can quickly lead to unplanned maintenance and downtime, at the end of the day hurting the bottom line.

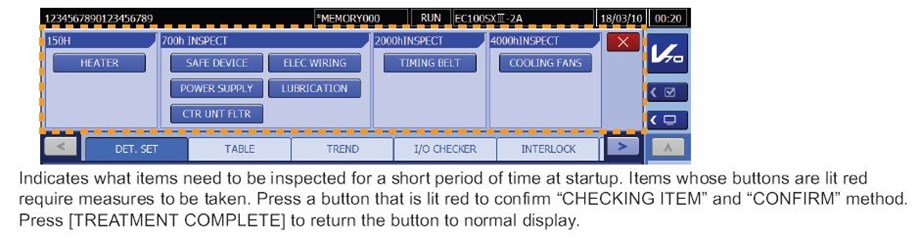

With Shibaura Machine’s V70 controller, technicians have the ability to reference the onboard Preventative Maintenance guide which offers a quick reference and help navigating both daily and periodic inspection requirements. The controller automatically prompts the technician to recognize the maintenance marker and offers a user friendly guide on how to perform these fundamental steps of inspection.

Simplify Preventive Maintenance

The goal of the Preventative Maintenance guide is to make inspections less cumbersome. Once utilized, this guide can help at reducing downtime while protecting your machine investment. The five important maintenance marks and their basic inspection requirements are outlined below.

Weekly

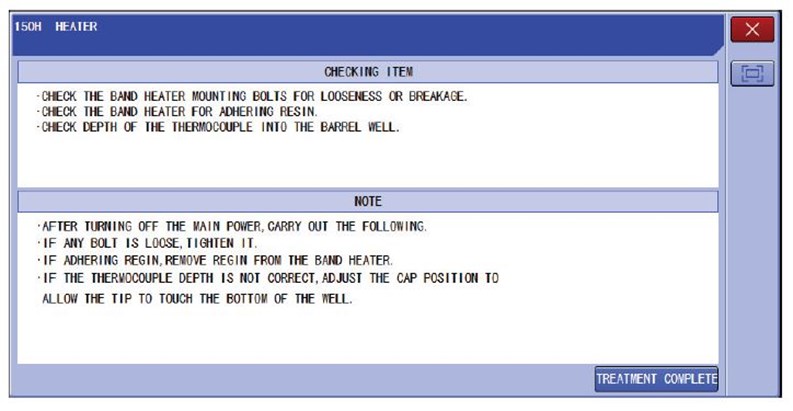

At approximately 150 hours, inspections of the ejector system and heaters should take place. This includes an in-depth inspection of the ejector system, heater bands, and thermocouple insertion in the barrel.

Monthly

Every 700 hours technicians should review specific aspects of the safety gates, mold installation bolts, barrel installation bolts, injection unit, barrel end cap and screw tip, machine lubrication, power supply, electrical wiring, air filters, and an overall machine cleaning.

Quarterly

Around 2000 hours a thorough inspection of the timing belts is necessary.

Semi-Annually

At the 4000 hour marker the guide will remind you to review the screw tip assembly and electrical components. It is also recommended for technicians to check the cooling fans on the control panel and cabinets, and perform an in-depth inspection of the machine lubrication.

Annually

8000 hours marks the annual inspection of the machine. This includes checking for abnormal noises and wear of bushings and sliding surfaces.

The Preventative Maintenance guide goes into complete detail as to how the technicians should perform these tasks. The guide provides the location to review, inspection method, and offers corrective action. Once the task is completed the notification can be reset.

Improve Your Approach to Preventative Maintenance

Utilizing the Preventative Maintenance guide, inspections do not have to be cumbersome and will provide beneficial effects to your overall maintenance approach. The prompted maintenance that the guide walks the technician through can not only reduce the frequency of unplanned downtime, but increase the productivity of your operation and raise profit margins.

Contact the Injection Molding team to learn more about the V70 controller and all its time-saving features.

Tel: (888) 593-1616

Contact us today to discuss how our preventative maintenance tools can help reduce unplanned downtime!

Related Articles View All Articles

Reduce Cooling Water Load with All-Electric Machines

ELK GROVE VILLAGE, IL, February 2, 2022 - Water cooling systems have long been used in hydraulic injection molding machines in order to keep the machine running smoothly. But imagine being able to reduce cooling water load requirements- it will allow you t...

Read moreImproving OEE with All-Electric Machines

ELK GROVE VILLAGE, IL, January 31, 2022 - Stops in production, whether planned or not, create Availability Loss on the factory floor. While it isn’t always possible to eliminate changeover time, being able to significantly reduce it along with unplanned do...

Read moreWhy Repeatability and All-Electric Molding Machines Go Hand in Hand

ELK GROVE VILLAGE, IL, January 23, 2022 - Repeatability in injection molding. Being able to offer this shot after shot means lower cost of operation and consistency. It is key to the production of parts in today’s competitive market and has a crucial influ...

Read moreLooking to Reduce Scrap? Why All-Electric Injection Molding Machines Are the Clear Choice

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving scrap rates in injection molding can have a large impact on increasing profitability. While there are many process improvements for scrap rate reduction, it is also important to consider the type of machi...

Read moreFaster Cycle Times with All-Electric Injection Molding

ELK GROVE VILLAGE, IL, January 6, 2022 - Considering changing out from hydraulic to all-electric machines in the new year, but trying to justify the change? Look no further than the improvements these machines can make to your cycle time. Being able to red...

Read moreHow Automatic Load Cell Calibration Helps Prevent Molding Defects

ELK GROVE VILLAGE, IL, December 29, 2021 - One of the key advantages of all-electric injection molding machines is the ability to monitor actual plastic pressure during injection via a load cell behind the screw, without the need for in-mold transducers. ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools