The Shibaura Machine Milling Machine Guide

ELK GROVE VILLAGE, IL, May 3, 2021

Maximizing productivity and getting the most value out of your milling machine investment is key whether you are a large manufacturing operation or smaller job shop. Making sure you are investing in not only high quality craftsmanship, but cutting edge technology offering the functionality your manufacturing operation needs is key.

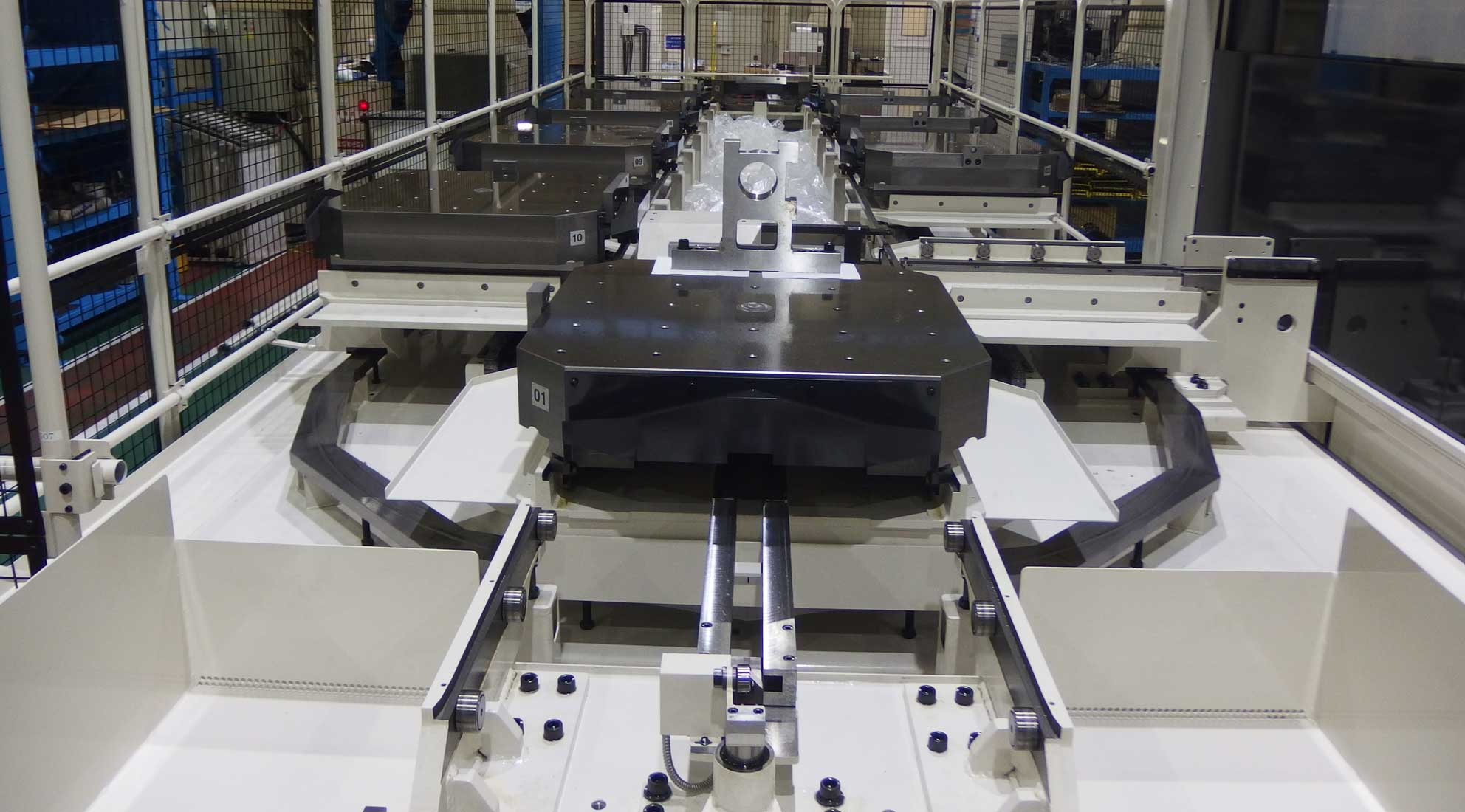

Shibaura Machine has developed and manufactured a full line of precision Milling Machine products that include vertical spindle and horizontal spindle orientation in platforms based on bridge style machines, horizontal boring machines, horizontal machining centers and 5 axes machines. As a one-stop shop for all milling machine requirements, we created this quick reference guide to help you make sure you select the appropriate milling machine for your operation.

How to Choose a Milling Machine

Selection of the appropriate milling machine solution is generally based on workpiece surface geometry, material, production requirements, accuracy and size and weight of workpiece. Shibaura Machine Milling Machines are available with multiple spindle power and rpm configurations, automatic tool changers, automatic pallet changers and full enclosure options with workpiece table size capacity starting at 40 inch up to our mother machine size machines.

Let’s takes closer look at vertical, horizontal and five axes milling machines

- Vertical milling machines are used for machining of a single surface or multiple surfaces when used with an optional indexing table. From an investment standpoint vertical machining centers are very cost effective. Shibaura Machine’s vertical milling machines offer the option of increased spindle speeds, high thermal stability and superior tolerance control.

- Horizontal milling machines on the other hand are used typically in conjunction with an integrated rotary table for machining of all 6 workpiece surfaces of a workpiece in 2 setups with tombstone fixturing or utilization of a boring spindle design. Shibaura Machine's horizontal milling machines come with a variety of spindle and table options.

- 5 axes machines are used for both 5 sided surfaces to reduce fixturing of the workpiece and full 5 axes contour machining when the cutting tool has to stay normal to the workpiece surface or at an inclined tool angle.

Determining the number of axes you need will also help narrow down your options. Generally milling machines have at least 3-axes, but a 4-axis or 5-axis milling machine with a tilt/and or rotating spindle or table design allows you to save time when machining different angles by eliminating workpiece setups. Shibaura Machine also offers a horizontal machining center with a quill design spindle for bore or extended reach milling applications. Shibaura Machine’s 5 axis milling machines solution offers combinations of speed power ranges, highly rigid machine designs and high accuracy allowing your shop to process an extensive range of different workpieces.

Let Us Help You Find the Right Milling Machine

It can be challenging deciding on the correct milling machine to invest in. Producing specific types of work or catering to certain industries like Aerospace, automotive, construction, space and defense and medical require certain functions and capabilities. Contact our team of machine tool experts to discuss your requirements and learn what milling machine is best suited for your shop.

Contact our machine tool team to learn more about our entire line of solutions.

Related Articles View All Machine Tools Articles

Have You Considered Your Machine Tool DNA from Mother Machines to Nano Machines?

ELK GROVE VILLAGE, IL, April 26, 2021A machine to make other machines possible. Any guesses on what that machine might be?From machining components for the largest airplanes, ships, trains, and even the largest earth moving equipment in the world, the mac...

Read moreAre You Getting World Class Design From Your Machine Tool Manufacturer?

ELK GROVE VILLAGE, IL, December 21, 2020 People throw out a lot of words when marketing these days. It’s hard to sift through fact or fiction. When a manufacturer states they offer world class design of their machine tools, what exactly should you be look...

Read moreDoes Your Machine Tool Offer True Auxiliary Equipment integration? Why It’s important.

ELK GROVE VILLAGE, IL, February 23, 2021 At the end of the day, machine tools are meant to help people make things. In today’s challenging economic climate many of us are looking to make things quicker, with less energy, and hurdles. Accomplishing this me...

Read moreMachine Tool Reliability- An Important Factor in the Manufacturing Process

ELK GROVE VILLAGE, IL, March 23, 2021When a machine tool fails it not only challenges due date commitments, but can lead to poor quality workpieces, slower production output, and downtime losses. Bottom line, if your machine tool isn’t reliable; it will gr...

Read moreMaximize Speed and Maintain Control with Tosnuc CNC Shape feature

ELK GROVE VILLAGE, IL, March 1, 2021 When purchasing a new CNC Machine Tool many customers find themselves still not being able to machine complex workpieces as fast as needed due to inconsistent feedrates or tool chip loads. Shibaura Machine has now dev...

Read moreBuilding Continued Value for Your CNC Machine Tools Investment

ELK GROVE VILLAGE, IL, April 13, 2021Having a partner that has your back when it comes to your machine tool investment is what Shibaura Machine provides.Machine tools that aren’t operating at peak efficiency and productivity means the factory is missing ou...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools