Shibaura Machine’s Quill Machining Strategy Provides Performance and Cost Advantage

ELK GROVE VILLAGE, IL, September 21, 2021

When it comes to obtaining the highest level of profitability in CNC shops, many go on the hunt for different technologies, tools, and processes. Often overlooked is quill (bar) style horizontal machining. Quills have an important role to play and can make a tremendous difference in your overall objective of keeping a competitive edge and growing profit margins.

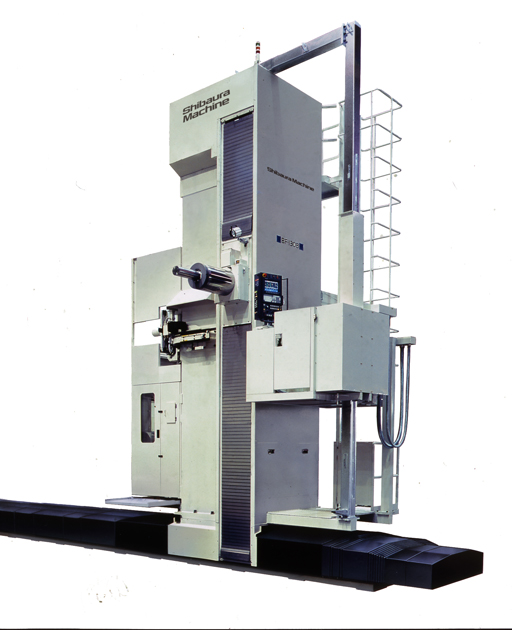

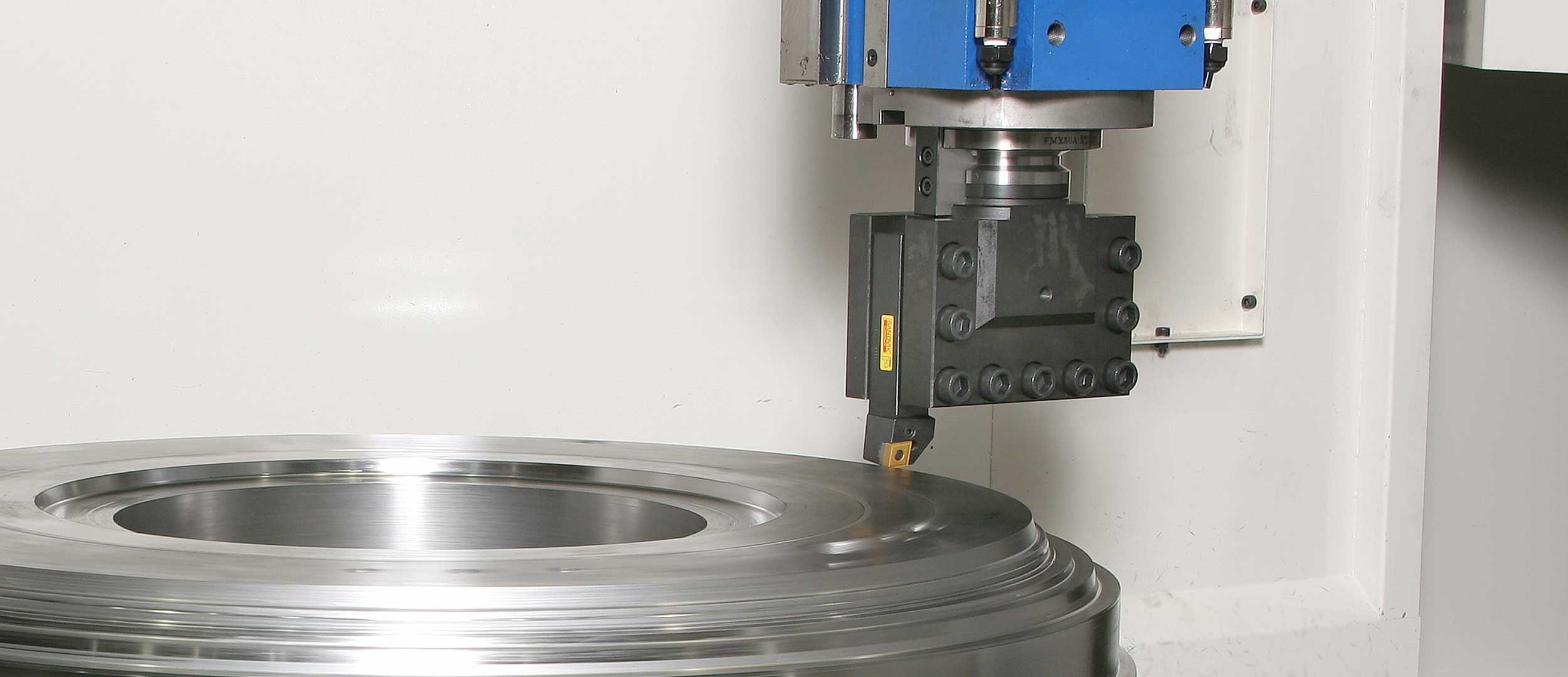

When it comes to helping shops optimize their machining processes, selecting the right quill on a horizontal boring mill or horizontal spindle machining center is extremely useful. A well-designed quill can provide the rigidity and accuracy required for close tolerances and offer the durability to assure a long lasting performance. Shibaura Machine brand quill style machines are often used in the leading machine tool users within the automotive, energy, aerospace and construction/mining industries.

Save Time and Money with Quill Machining

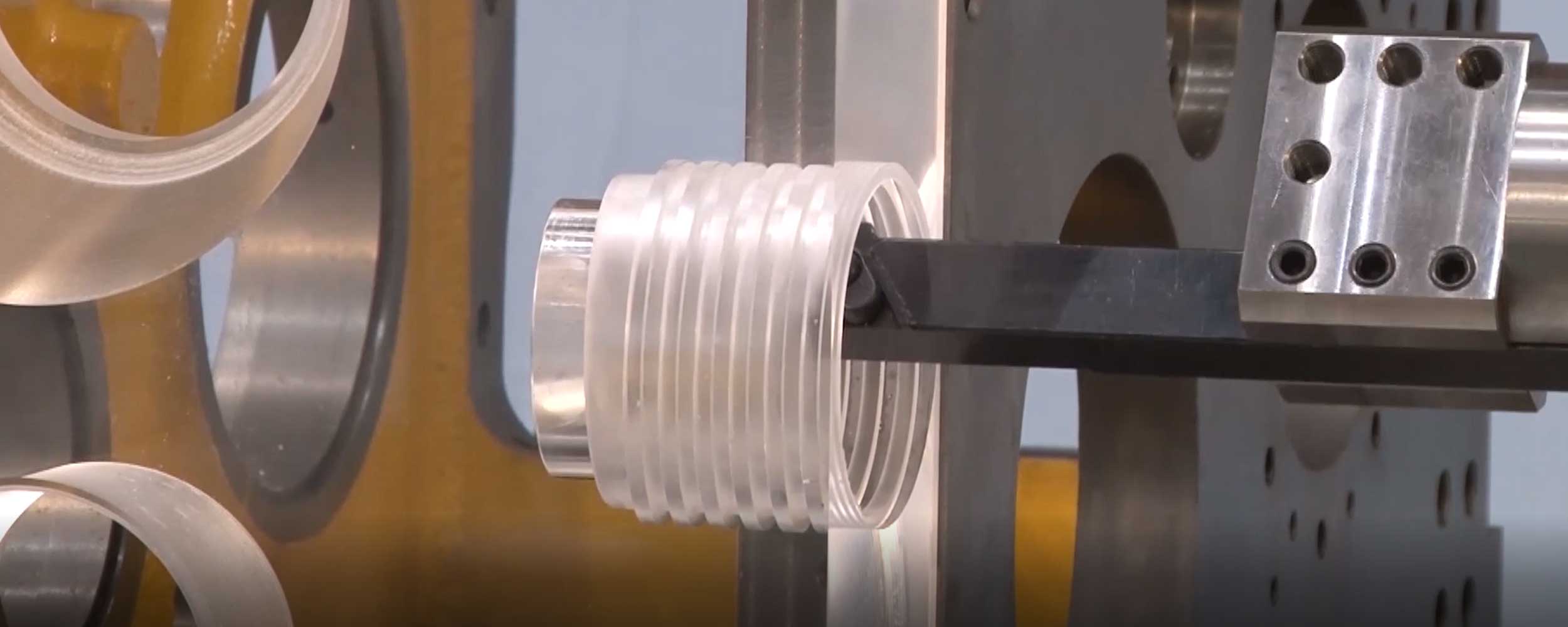

It is more economical and efficient for machine tool users to implement a quill design spindle instead of using numerous extended tool lengths to increase work zones to reach each surface or bore. Using our standard quill interface to suit unique requirements can be used over and over again offering cost savings.

When a shop uses a quill style horizontal machine it also allows them to reduce the number of cutting tools of varying lengths that are normally needed for different applications. This offers a significant performance boost by saving users time by eliminating unnecessary tool changes.

Gain a True Advantage

Besides time and cost savings, quill machining can make you stand out from the crowd quickly. The accuracy and repeatability of Shibaura Machine quill horizontal boring machine models make them an ideal option for face milling, heavy duty boring or drilling operations. Additionally, the high rigidity and overall performance offered gives shops peace of mind when it comes to reliability and overall lifespan.

Shibaura Machine Company, America offers a full range of horizontal boring machines models (BTD, BTH, BP, BF and BSF) from 110mm, 130mm, 150mm to 180mm diameter quills, otherwise known as bars in both table type, planer or floor type machine tools. Our 1000mm pallet size horizontal machining center model BM-1000Q also comes with a 200mm diameter quill.

Contact us to learn more about our horizontal boring mills and horizontal spindle machining centers that offer quills.

MT-Sales@shibaura-machine.com.

Learn more about our machine models.

Related Articles View All Machine Tools Articles

Enhance Versatility with Shibaura Machine’s Orbit Boring Function

ELK GROVE VILLAGE, IL, September 14, 2021Whether your shop has high speed finishing or heavy duty machining applications, orbit boring is worth a consideration. With Shibaura Machine’s orbit boring function you can not only remove metal faster, but it is w...

Read moreShibaura Machine Discusses Opportunities to Improve Machine Tool OEE

ELK GROVE VILLAGE, IL, September 7, 2021How many times is your machine “getting it right the first time” compared to what it should be producing in a set time? This is the basis of determining Overall Equipment Effectiveness (OEE), a key performance indica...

Read moreOptimize Innovation with Siemens Realize Live Virtual Event

ELK GROVE VILLAGE, IL, August 31, 2021Every industry comes with its own set of unique manufacturing requirements. Whether it be complex shapes, large part sizes, or the use of exotic metals, having partners that provide specific solutions to meet those cha...

Read moreOptimize Metal Removal Rates with a High Efficiency Machining Strategy

ELK GROVE VILLAGE, IL, August 23, 2021Efficiency is a key advantage when it comes to being a competitive shop. In addition the ability to provide speed and precision with a machine from Shibaura Machine is a huge advantage when attempting to maximize Metal...

Read moreHow Shibaura Machine Vertical Turning Lathe Optimize Metal Removal Rates

ELK GROVE VILLAGE, IL, August 17, 2021Cutting optimization is a key aspect to a more productive machine and competitive foundation. But as many machinists will tell you there are many challenges when it comes to achieving optimal metal removal during this...

Read moreHigh Performance Turning Machines: Uncomplicated, Efficient, Cost-Effective

ELK GROVE VILLAGE, IL, August 10, 2021For many machine shops it might feel like you are producing parts just fine with your existing equipment. To a certain extent, you are. But in order to gain an advantage, manufacturers must reemphasize profitability in...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools