Looking to improve chip filtration on your machine tool? Consider this.

ELK GROVE VILLAGE, IL, December 8, 2021 -

Maximizing machine tool output is the goal for today’s industrial manufacturing applications. Being able to machine as many quality parts in the shortest amount of time allows for higher profitability and return on investment. However, machining of these parts generates a high volume of chips which can become time-consuming to constantly manage.

Shibaura Machine Company, America offers our machine tool customers an easy solution to automate the chip management process. By using a Jorgensen EcoFilter® you can efficiently and expediently remove these chips, separating them from the coolant, where they can easily be disposed of and recycled.

Flexible & Cost-Effective

The Jorgensen EcoFilter® offers numerous advantages for those using turning, milling, and boring machines to increase productivity and profitability. With the EcoFilter® you are able to spend less time performing tank cleanout by reducing the number of chips entering the coolant tank which improves machine uptime. The consistently cleaner coolant positively affects the tool life of both the cutting tools and coolant pump.

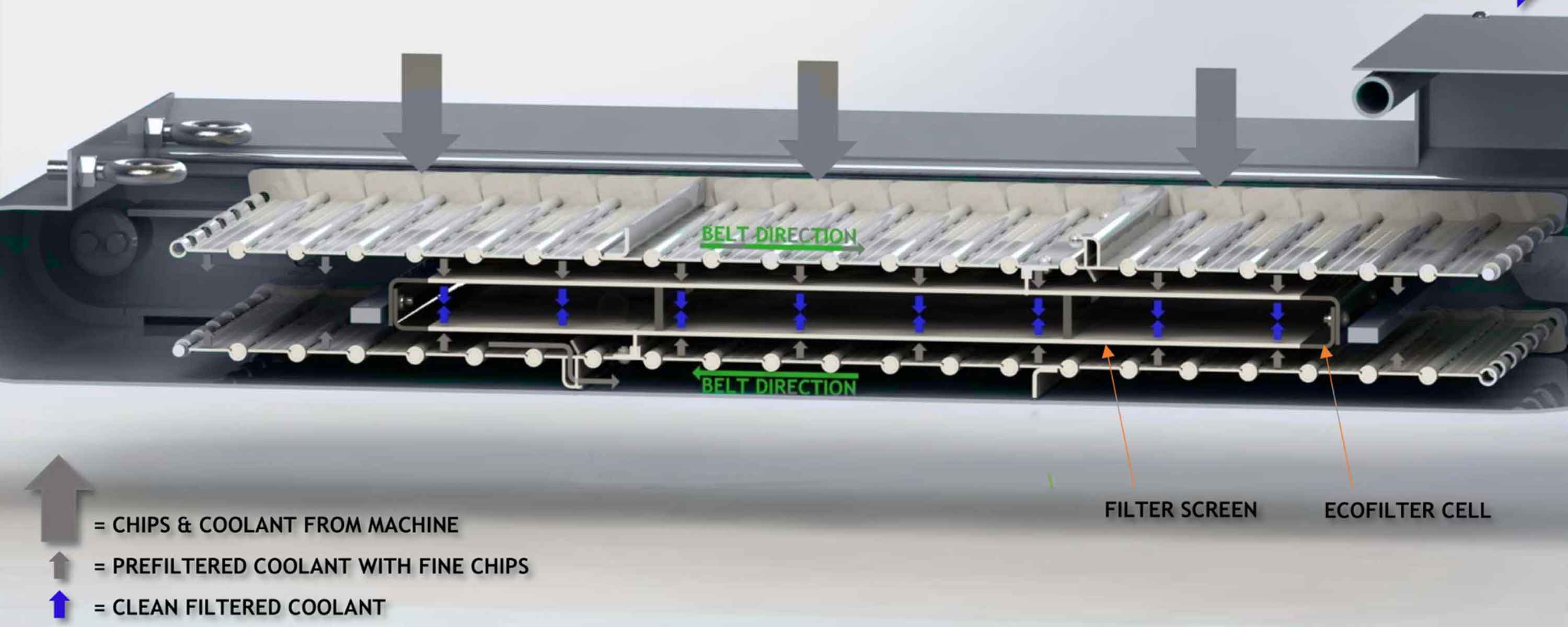

The process is simple and straightforward:

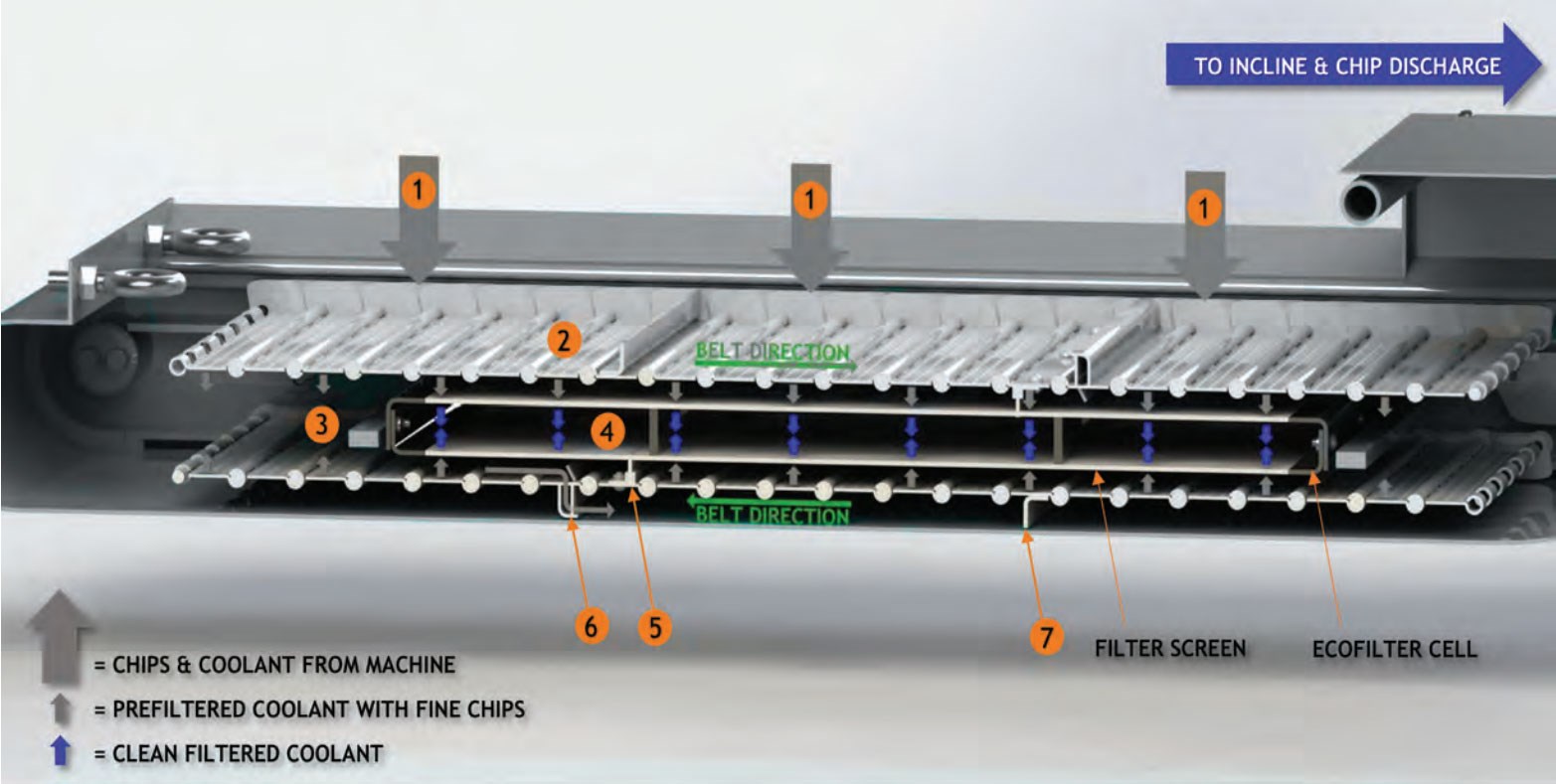

- Chips and coolant enter the conveyor’s load section

- Large chips and/or stringers are carried out by the hinged or scraper belt depending on your application.

- Coolant and fine chips flow to the section in between the runs of the belt, where the EcoFilter® cell is located.

- Fine chips are separated as the coolant passes through the filter cell. Clean filtered coolant flows from the inside of the filter cell, out of the side of the conveyor, and into the coolant tank.

- Brushes continuously wipe fine chips from the surface of the filtration cell, keeping the cell clean for coolant to pass through.

- Filtered chips can exit in between the runs of the belt through the bottom run via the patent pending CleanCleat® system, finding their way to the bottom of the conveyor casing.

- Fines that migrate to the bottom of the casing are scraped up and around to the top run of the belt, where they are finally discharged.

Customers may also convert the “EcoFilter® ready” conveyor to an EcoFilter® with a simple field retrofit kit and with the eco-friendly design you will never require filter consumables.

Learn More

Your coolant quality plays a key role in maximizing your machine tool output. In order to achieve clean coolant, removing the fines and chips is necessary. The Jorgensen EcoFilter® allows for easy automation of this process and is an important option to consider including with your next machine tool purchase.

Related Articles View All Machine Tools Articles

Spotlight: Machine Tool Customer Support Team

ELK GROVE VILLAGE, IL, December 2, 2021 - When customers purchase from Shibaura Machine, they know they are getting a high-performance machine tool. Ensuring you maintain the high-performance of your investment is just as important, if not more, then the i...

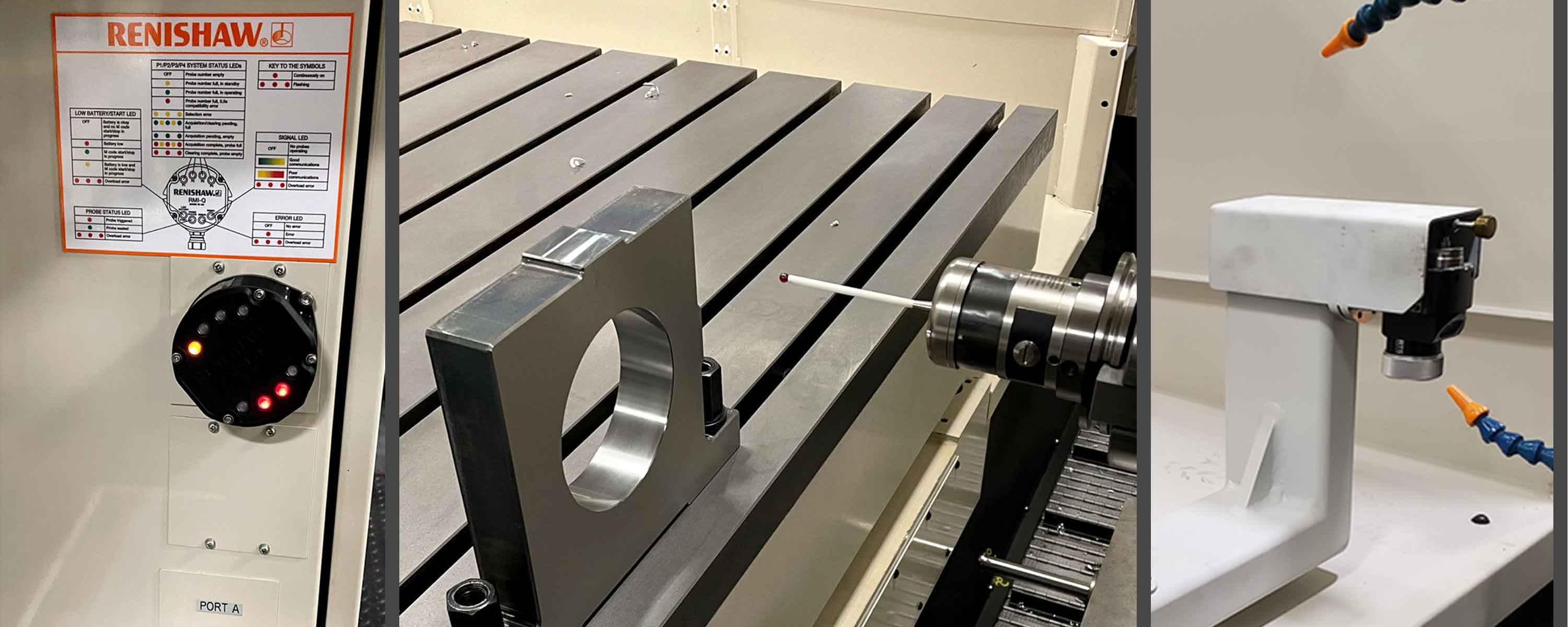

Read moreAutomated Machine Tool Health Checks Improve Productivity

ELK GROVE VILLAGE, IL, November 22, 2021 - Time is money. Being able to quickly identify problems when it comes to machine set-up, collisions, and wear can help shops save on both performance and profitability. Probing also offers both an easy and reliable...

Read moreHighlighting the Renishaw OSP60 Probe for Your Machine Tool

ELK GROVE VILLAGE, IL, November 15, 2021 - One constant in manufacturing is the need to focus on operating margins in order to remain competitive. What are the best ways to improve productivity and precision while boosting profits?Probing has been a long e...

Read moreUnderstand the Benefits of a Tool Setting Probe for Your Shibaura Machine Tool

ELK GROVE VILLAGE, IL, November 9, 2021 - Going into 2022 shops are focused on ways to improve workpiece quality, while saving time and money. One of the most efficient ways to optimize your processes from the ground up is to consider adding a tool setter....

Read moreAdding a Workpiece Inspection Probing System to Your Machine Tool Is Worth Considering

ELK GROVE VILLAGE, IL, November 2, 2021 - As machine tool automation advances, more manufacturers are looking towards the addition of a inspection probing system to help them make a bigger impact on their performance and profitability. That is why Shibaura...

Read moreHow Shibaura Machine Builds Quality into Every Machine Tool

ELK GROVE VILLAGE, IL, October 25, 2021 - Building a machine tool from a geometry standpoint can be equated to building a house. Just like a house needs walls to be square, floors to be flat, and structural components need to be aligned the same principles...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools