Machining Large and Complex Workpieces? Consider These Machine Specs.

ELK GROVE VILLAGE, IL, March 21, 2022 -

When it comes to machining large workpieces you need an equally large machine tool. While that might seem obvious, there are also a couple of other less than obvious factors to consider when choosing your next large work zone capacity machine tool to make sure it is capable of delivering stable machining and high-quality, accurate workpieces.

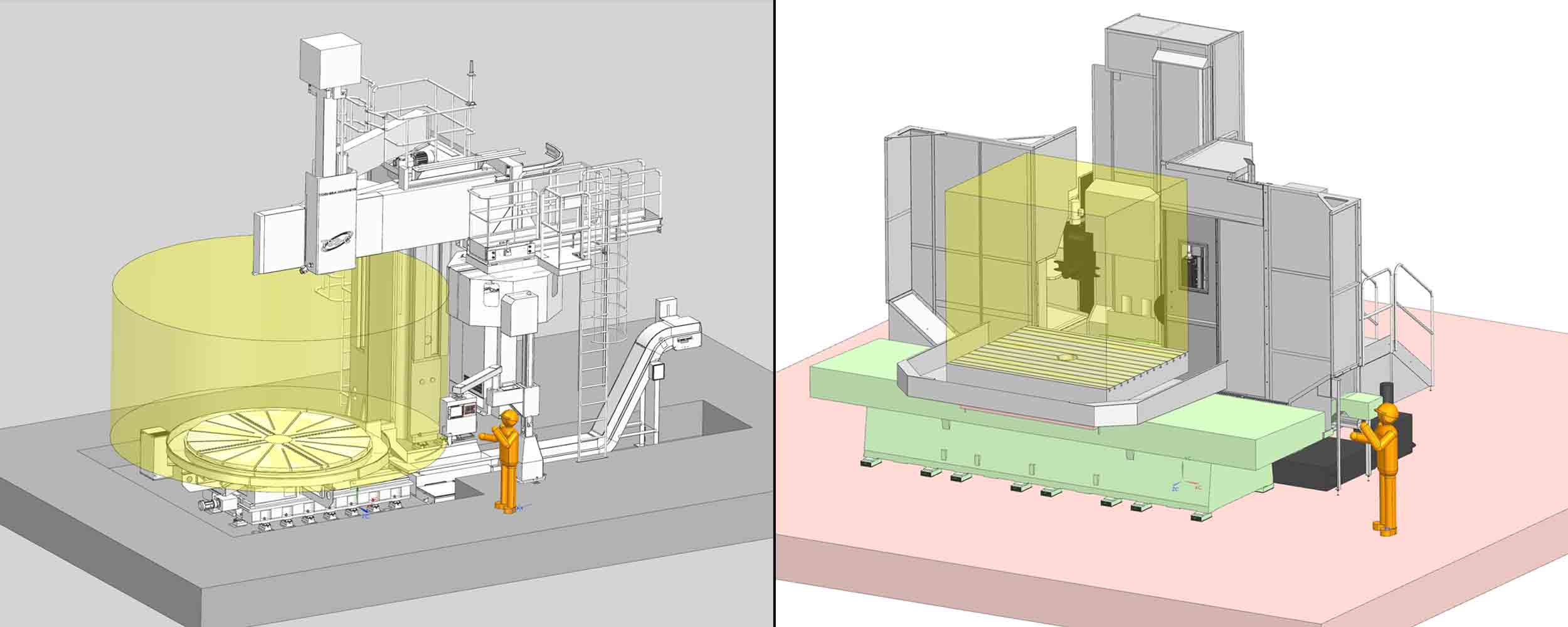

Two of the most common challenges associated with large part machining are machine swing diameter and axes travel to machine workpiece details. Many machine tools available today don’t meet the requirements of machining large or complex workpieces. Shibaura Machine has engineered both vertical turning and horizontal boring machines that take these challenges into account and incorporated several important design factors beyond simply “designing a large machine”.

Swing Diameter

The swing diameter is the maximum part size that can fit within the work zone without interference or collision with machine components. This measurement can help you narrow down the best CNC machine tool for your application. The TSS-C vertical turning series and BTH series horizontal boring machines from Shibaura Machine have some of the largest swing dimensions in the machine tool industry.

Axes Travel

The axes travel of the machine defines the ability of the machine to position the tool in the work zone to be able to machine the workpiece details. When creating complex parts, non-conventional shapes, or designs with deep and narrow cavities having sufficient axes travel will greatly improve the overall efficiency of the machine tool.

Shibaura Machine offers customers the benefits of conventional 3 or 4 axes machines, but also 5 axes, 3+2 machining on both the TOSNUC and FANUC CNC controls. The 5 axes, 3+2 axes machining operations are now as simple as 3 axes machining.

The Machine Makes a Difference

The complexity and type of geometry of your workpiece often dictate what size of machine you will need to consider. Picking the right size machine tool can make the difference between producing a large part or not. Contact the Machine Tool Team to discuss your requirements and find the best solution for your large and complex workpieces.

Related Articles View All Machine Tools Articles

What Machining Applications are Best Suited for a Box Way Axes Guide System?

ELK GROVE VILLAGE, IL, March 14, 2022 - So, when should you use a box way axes design guideway system?Shibaura Machine’s vast range of machining solutions allows us to supply customers with a box way guide system on our machine tools in addition to linear ...

Read moreLooking to Reduce Machine Tool Setup Time? Read This.

ELK GROVE VILLAGE, IL, March 07, 2022 - Time is money. This is why so many shops find themselves looking to reduce their machine tool setup time. When the machine is not running, it’s not making money- a simple fact.In order to maximize machine tool effici...

Read moreLooking to Reduce Machine Tool Setup Time? Read This.

ELK GROVE VILLAGE, IL, March 07, 2022 - Time is money. This is why so many shops find themselves looking to reduce their machine tool setup time. When the machine is not running, it’s not making money- a simple fact.In order to maximize machine tool effici...

Read moreImprove Part Program Usability with the TOSNUC 999 Macro Programming Function

ELK GROVE VILLAGE, IL, February 22, 2022 - Macro programming for CNC machining provides shops countless benefits. It offers both power and flexibility, allowing machinists to implement improvements in just about every facet of a CNC environment. Many shops...

Read moreOptimize Productivity With These Strategic Machine Shop Layout Ideas

ELK GROVE VILLAGE, IL, February 14, 2022 - Take a look at your machine shop floor. Is it maximizing space and enabling the most productive environment?One of the most overlooked solutions to improving workflow and production in CNC machining is shop floor ...

Read moreImprove CNC Operation Efficiency with Customized Keys on TOSNUC 999

ELK GROVE VILLAGE, IL, February 08, 2022 - While CNC machines are excellent at doing what they are programmed to do, it is the machine operator's role to make sure they are commanded accurately. That is why being able to properly navigate the control panel...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools