Consider High-Pressure Coolant to Improve Chip Management

ELK GROVE VILLAGE, IL, May 16, 2022 -

Managing machine tool cutting variables such as feeds, speeds and depth of cut play a key role in eliminating unpredictable cutting tool wear and poor chip management. Incorporating a high pressure coolant system will provide an ideal advantage when applied properly to the tool cutting zone. This is particularly useful for industries like aerospace, automotive, and energy which commonly use special workpiece materials that are difficult to cut. Other workpiece material classes will also enjoy the benefits of a high pressure machining strategy.

With manufacturers spending millions each year on cutting coolants, high-pressure coolant delivery has become increasingly popular to enable CNC machine tools to improve overall equipment efficiency (OEE).

High-Pressure Coolant Makes a Difference

Implementing a high-pressure coolant system creates an opportunity for shops to improve productivity and provide measurably reduced cost per part.

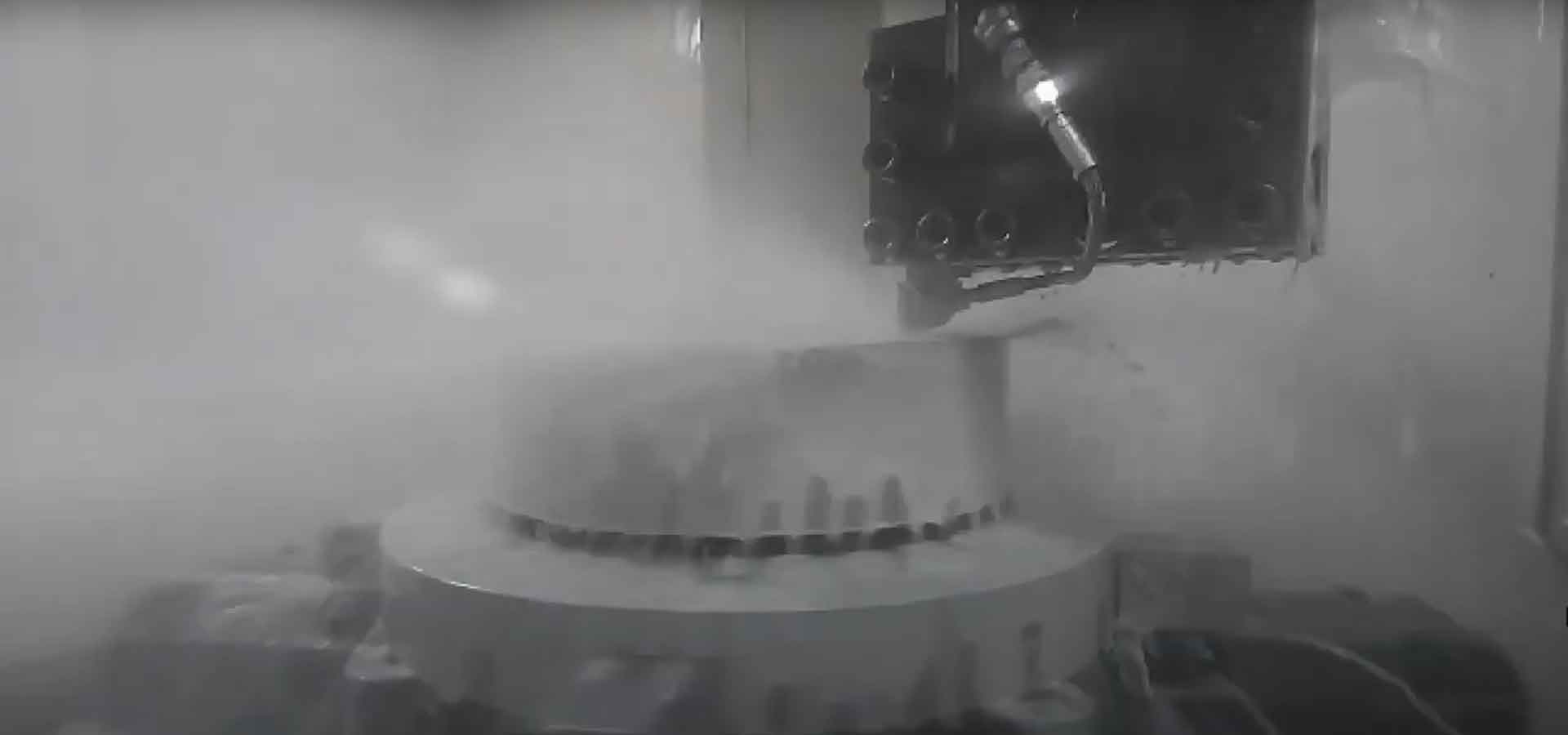

The addition force of high-pressure coolant increases localized pressure. This eliminates the common problem of superheated steam and prevents oxidation of workpieces and tools by allowing the coolant to successfully reach the tool tip, preventing heat damage that results in premature tool failure.

Additionally, with chips being kept at a lower temperature they are able to break easier from the cut removed from the point of cut. With the power of the high pressure, chips are blasted away from the tool which prevents additional wear. This allows for an easy and effective way to process the cutting tool chips.

This video was produced prior to April 1, 2020. Our company name has changed to Shibaura Machine.

The coolant entering between the workpiece material and the rake face of the cutting tool allows for effective lubrication and cooling near the cutting point. This enables faster and more precise cuts with the cutting tool due to heat being reduced. Machine operators are also able to moderate the temperature in the cutting zone to maintain consistency.

We Can Help

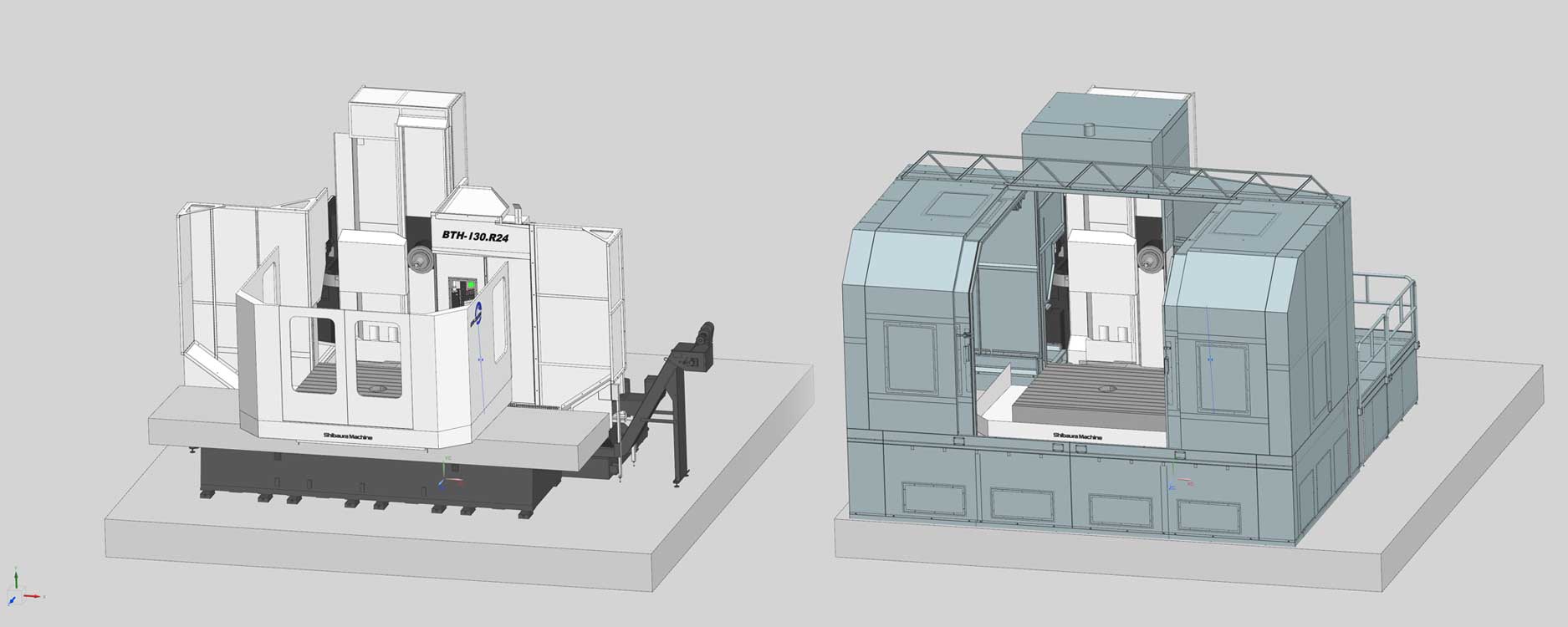

Shibaura Machine has several models of machine tools that are high-pressure coolant compatible, prepped for powering most any machining application. Contact our Machine Tools team to learn which model will prove most effective for your shop.

Related Articles View All Machine Tools Articles

Understanding the Design Principals of Machine Enclosures

ELK GROVE VILLAGE, IL, May 9, 2022 - Machine enclosures have quickly become mainstream as a way to ensure your machine is operating as efficiently as possible and improve your work zone environment. The enclosure not only contains chip and coolant but dete...

Read moreThe Future of Machining in the EV Market

ELK GROVE VILLAGE, IL, May 2, 2022 - The Electric Vehicle (EV) market continues to shake up the entire supply chain of the automotive industry with its unprecedented growth rates. Between 2020 and 2026, the size of the global EV market is expected to incre...

Read moreExpand Capabilities with Horizontal Boring Mill Table on Table Configuration

ELK GROVE VILLAGE, IL, April 18, 2022 - A typical Horizontal Boring Machine (HBM) excels at machining two bores in perfect parallelism. While the name indicates boring, these machines can be used for many different machining applications. With the addition...

Read moreImprove Your Approach to Machine Tool Maintenance

ELK GROVE VILLAGE, IL, April 13, 2022 - With machine availability being a key metric to the production capability of your factory it leaves us asking, is there a better way to maintain and reduce downtime of your machine tool? The answer is YesDepending on...

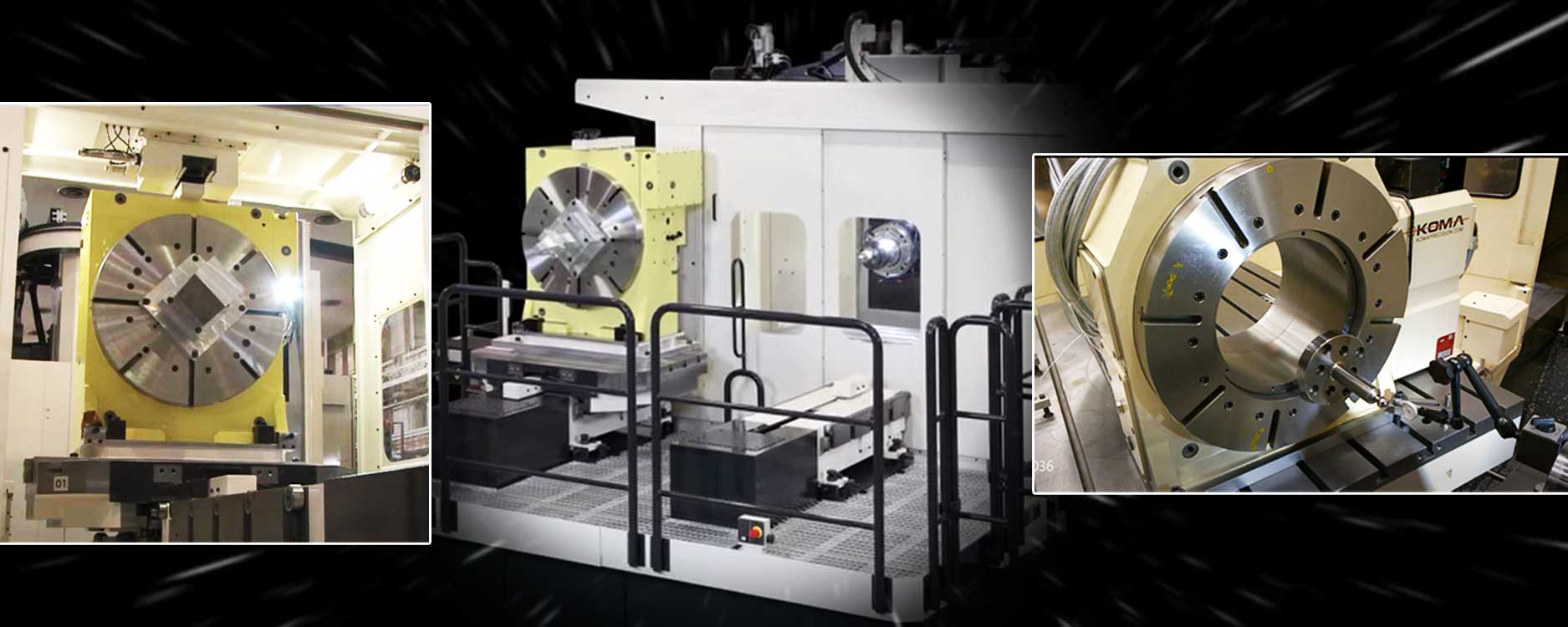

Read moreVersatility Meets High Performance With the TSS VTL Table Slide Mechanism

ELK GROVE VILLAGE, IL, April 4, 2022 - The power to multi-task in shops is increasingly becoming a valuable tool and competitive differentiator. With the right multi-tasking machines, manufacturers are able to reduce cycle times by offering a single setup,...

Read moreIncrease Double-Column Machine Capabilities With These Attachments

ELK GROVE VILLAGE, IL, March 28, 2022 - When it comes to choosing a double-column machine there are several considerations you’ll want to take. Is it high-performance, does it provide the stability and power required to deliver uninterrupted precision? Can...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools