Twin Ballscrew Axes Design Offers a High level of Positional Accuracy and Repeatability in Bridge Mill Machine Tool

ELK GROVE VILLAGE, IL, November 22, 2022 -

On most milling or turning machine tools, single ballscrew axes designs are used in conjunction with guide surface for table travel, spindle-head travel and column travel.

In order to achieve the high repeatability and accuracy desired when positioning the Z-axis spindle a twin ballscrew design is ideal, especially on a double column type machining center.

Why Twin Ballscrews?

In machining applications it's necessary to provide balanced movements. To balance the movement of the Z-axis, a ballscrew is located on the right and left sides of the spindle which eliminates the need for a counter-weight system meaning reduced weight when positioning the vertical Z-axis. The twin ballscrew design also allows the ability to feed the spindle (Z-axis) more accurately by directly coupling the servo motor to the ballscrews. By eliminating the design of a counter-weight system altogether, the constant source of trouble when using high-speed machining applications and the frequent maintenance of the counterbalance system are all eliminated.

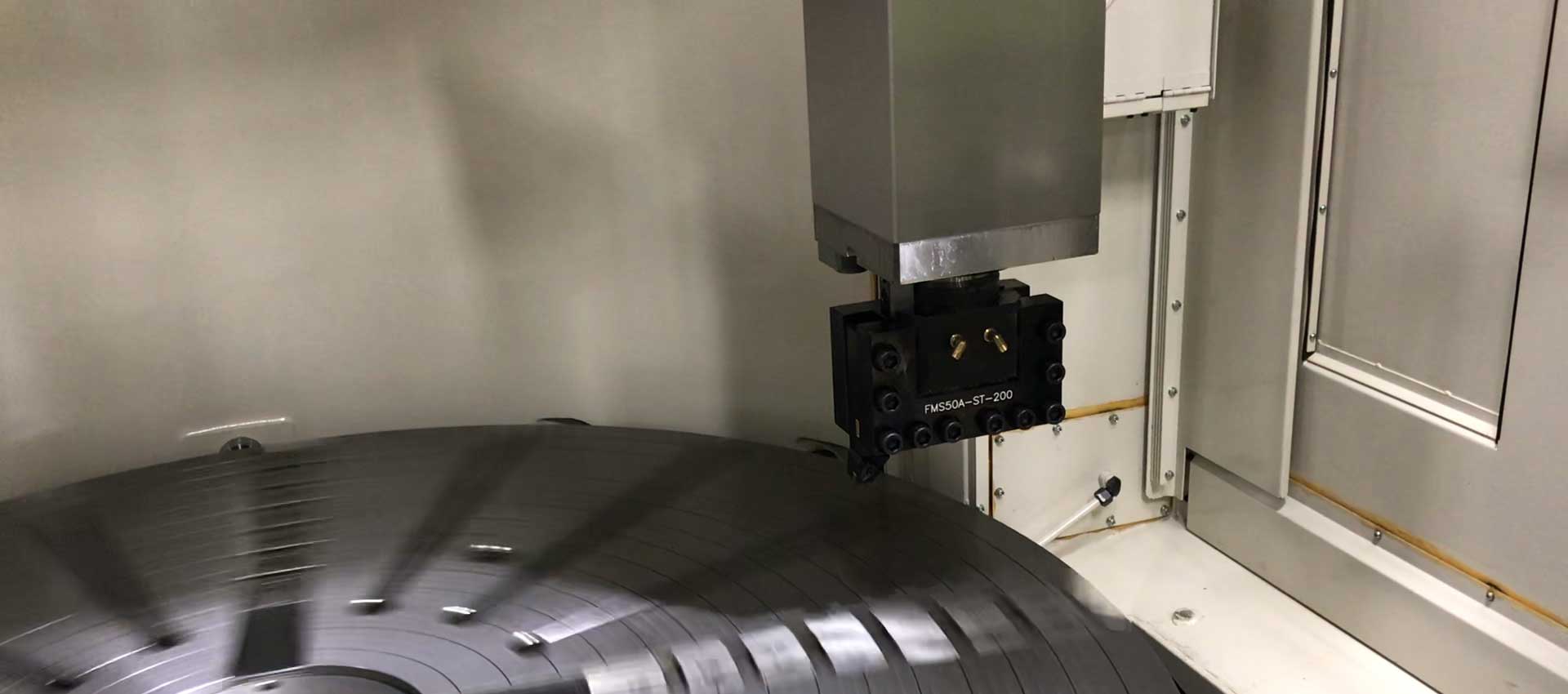

Twin ball screws are an ideal way to achieve high-speed machining with a bridge mill. For example, Shibaura Machine’s MPF-FS Series, Double Column Type Machining Center provides this capability. The energy-saving machine offers the twin ballscrew on the Z-axis, driving both sides of the ram to help in achieving a high level of accuracy and speed on the Z-axis.

Designed For High Accuracy and Repeatability

The design of the Z-spindle axis on the MPF-FS Series, Double Column Type Machining Center offers an ideal solution to achieve high-speed, highly accurate and repeatable machining processes for a wide range of industrial applications.

Contact the Machine Tool team to learn more about our Twin ball screw design and how it plays a key role into the high speed processing capabilities of this machine tool.

Related Articles Articles

Three Important Factors to Consider When Choosing a Machine Tool Manufacturer

ELK GROVE VILLAGE, IL, November 15, 2022 - Being able to plan and deliver predictable results is key to maintaining a competitive edge in manufacturing. When it comes to machine tools, the company you choose to purchase from plays a big role in ensuring th...

Read moreThe Shibaura Machine Standard for Tool Holders

ELK GROVE VILLAGE, IL, November 8, 2022 - What to Consider When Choosing a Tool Holder When it comes to machining accuracy of machine tools and product quality, tool holders can be highly influential. Shibaura machine tools are designed to use a high quali...

Read moreImprove Efficiency and Grow Opportunity with a Multi-tasking Machine Tool

ELK GROVE VILLAGE, IL, October 24, 2022 - Being able to combine functions in a single machine tool has long allowed us to save time, save money, and increase efficiency. Everything from smartphones to printers, even gym equipment, has been transformed to p...

Read moreConsiderations when using large cutting tools

ELK GROVE VILLAGE, IL, October 18, 2022 - When searching for the appropriate tooling for your machining application there are many different factors that should be considered. From speeds and feeds to workpiece shape and material, and even how much power d...

Read moreIs High Feed Machining Right for My Shop?

ELK GROVE VILLAGE, IL, October 04, 2022 - Getting parts out the door with the highest efficiency and lowest cost has remained a constant productivity marker for machine tool shops. High feed machining is a process that has been around for a while and when ...

Read moreShibaura Machine is Bringing Service and Support Teams Into Your Shop

ELK GROVE VILLAGE, IL, September 30, 2022 - With machine tools performing constant repetitive tasks maintenance is to be expected, but to what extent? Being able to better plan for preventative maintenance and control downtime can make a huge impact on you...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools