Making Sense of Machine Tool Thread Milling for Your Application

ELK GROVE VILLAGE, IL, January 30, 2023 -

When it comes to adding threads to a workpiece, the choice of method can make a significant difference to the outcome.

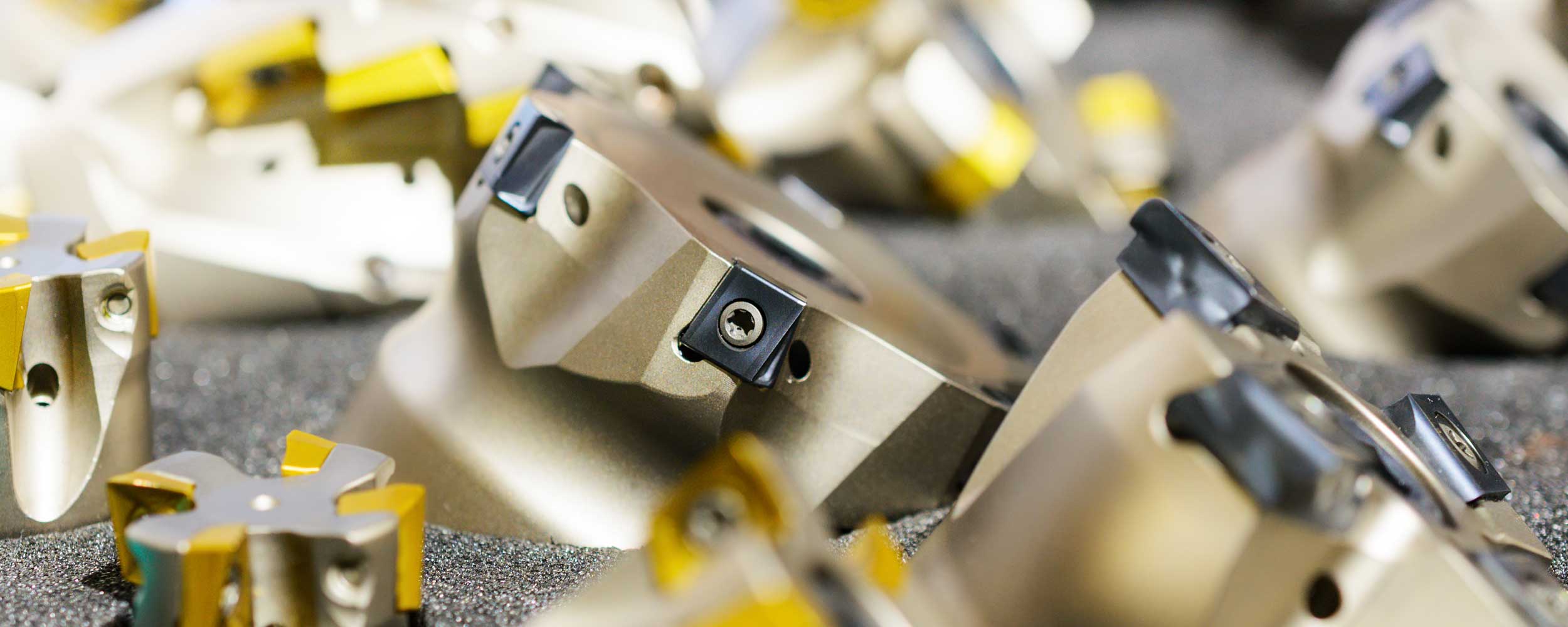

For parts made from difficult-to-machine materials, thread mills have become an increasingly popular option. Unlike traditional tapping methods, thread mills use a cutting tool that is smaller than the hole size, making them well-suited for low-volume, high-precision applications. With thread milling becoming a well-established method in the industry, it's worth considering as an alternative approach.

Machinist Advantages to Using Thread Milling

1. Increased Efficiency

Machinists are able to create threads on a workpiece in one pass, without the need for multiple setups.

2. Greater Versatility

Thread milling tools can be made with a variety of cutting materials and can produce threads in a wide range of materials, including hard materials such as titanium and stainless steel.

3. Improved Accuracy

Shibaura Machine’s machine tools are equipped with advanced control systems that allow for precise and efficient thread production, ensuring high accuracy and repeatability of the threads.

4. Cost-effective

Thread milling requires no additional tools to change diameter, which also means fewer taps to store and less overall maintenance of tools.

5. Flexibility

Thread milling can be used to produce both internal and external threads, and can also be used to create threads on irregularly shaped parts.

The medical device and aerospace industries particularly benefit from thread milling. It offers a better quality thread than traditional methods by allowing for clearance to evacuate chips that would otherwise be forced to evacuate through the thread form.

Experience the Precision and Efficiency of Thread Milling with Shibaura Machine Tools

Shibaura Machine machine tools are a preferred choice for thread milling because of their precision and reliability. We offer a wide range of CNC thread milling machines that are designed to produce threads with high accuracy and repeatability. The machines are equipped with advanced control systems that allow for precise and efficient thread production. Contact the Machine Tool Team to learn more today.

Related Articles Articles

Supporting Success: Shibaura Machine Tools' Growing Commitment to Customers

ELK GROVE VILLAGE, IL, January 25, 2023 - When purchasing a machine tool from Shibaura Machine, you can expect high-performing equipment. Customer satisfaction is our top priority, and we go above and beyond to ensure that our customers receive the best se...

Read moreFind Your Ideal Chip Conveyor Set Up

ELK GROVE VILLAGE, IL, January 10, 2023 - One way manufacturers can work to maximize machine tool output is with the use of a chip conveyor. Not only does it keep the workspace clean and clear of chips, but makes it easier for operators to access the machi...

Read moreGet the Most Out of Your TOSNUC 999 CNC Controller

ELK GROVE VILLAGE, IL, January 04, 2023 - Going into 2023 are you taking advantage of everything your CNC control can do for you? The TOSNUC 999 provides plenty of manufacturing advantages with its user-friendly interface and functions. Designed with the m...

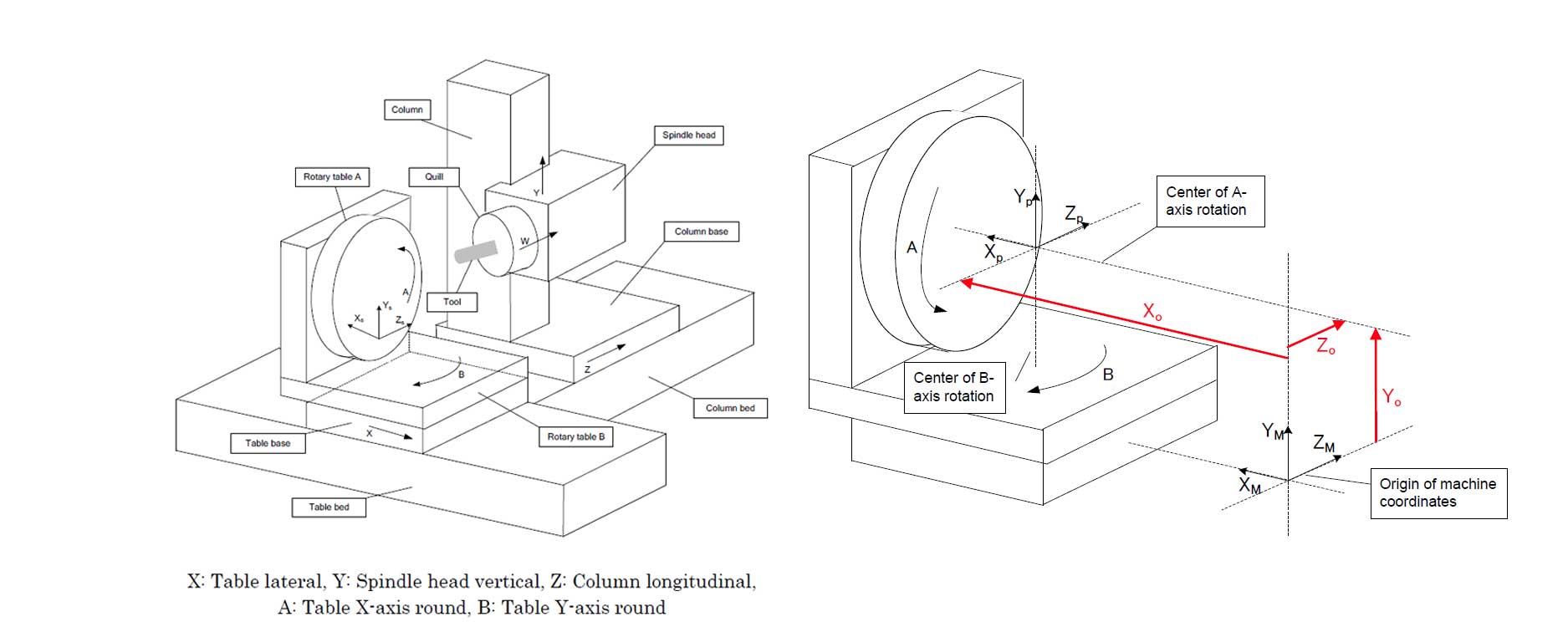

Read moreExpand your Horizontal Boring Machine Capabilities with Additional Axis Control

ELK GROVE VILLAGE, IL, December 14, 2022 - Depending on a parts’ geometry, having 5-axis machining can have a major impact on your productivity and quality. Being able to move the cutting tool along five axes allows for a high degree of flexibility and pre...

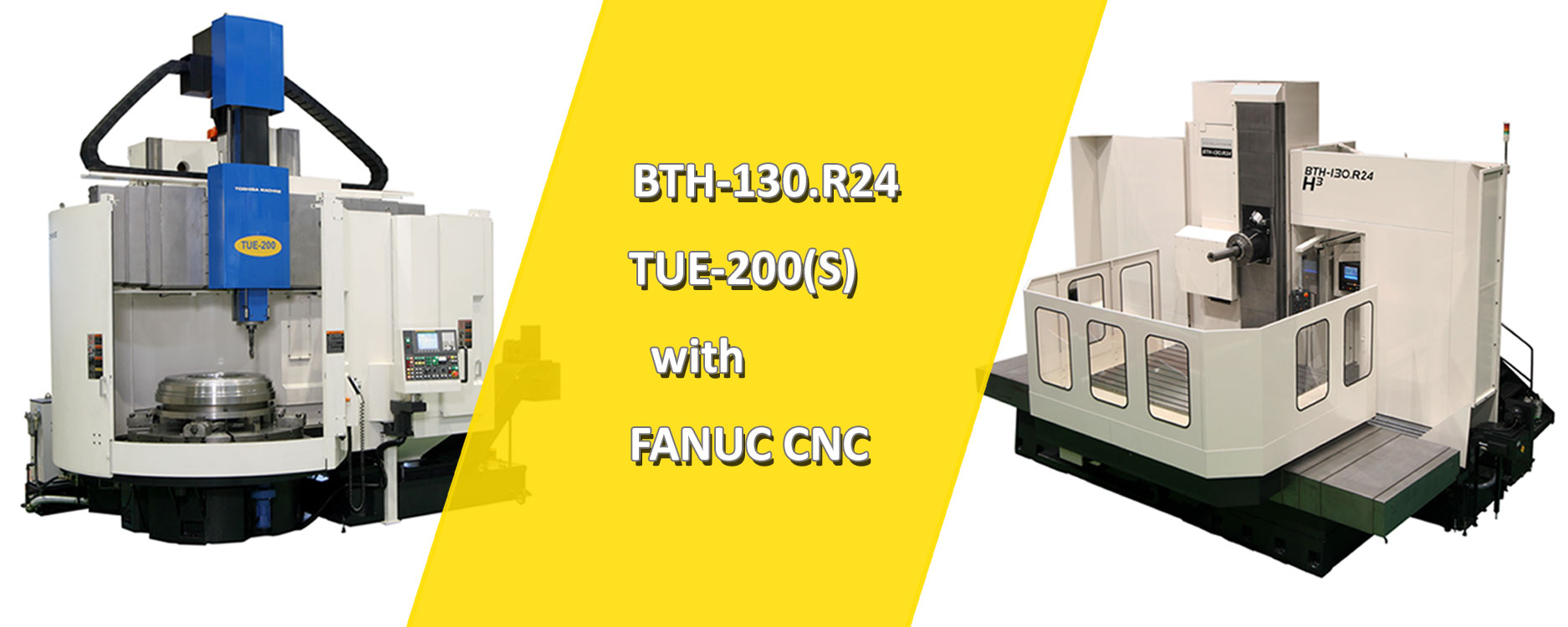

Read moreEnhance Your Machine Tools Performance With These FANUC CNC Control Options

ELK GROVE VILLAGE, IL, December 06, 2022 - Shibaura Machine is proud to offer machinists the FANUC CNC control as an option with many of our high performance machine tools. As a world-class technology leader in CNC control designs, the capabilities of toda...

Read moreSaving on Perishable Tool Costs Starts with Machine Tool Quality

ELK GROVE VILLAGE, IL, November 30, 2022 - Every shop is challenged with ways to maximize revenue while minimizing costs. That is why when you are looking to make an investment on a new machine tool it goes way beyond the initial price tag. With extensive ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools