Maximizing Efficiency in Machining with the Right Angle Head Attachment on your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 14, 2023 -

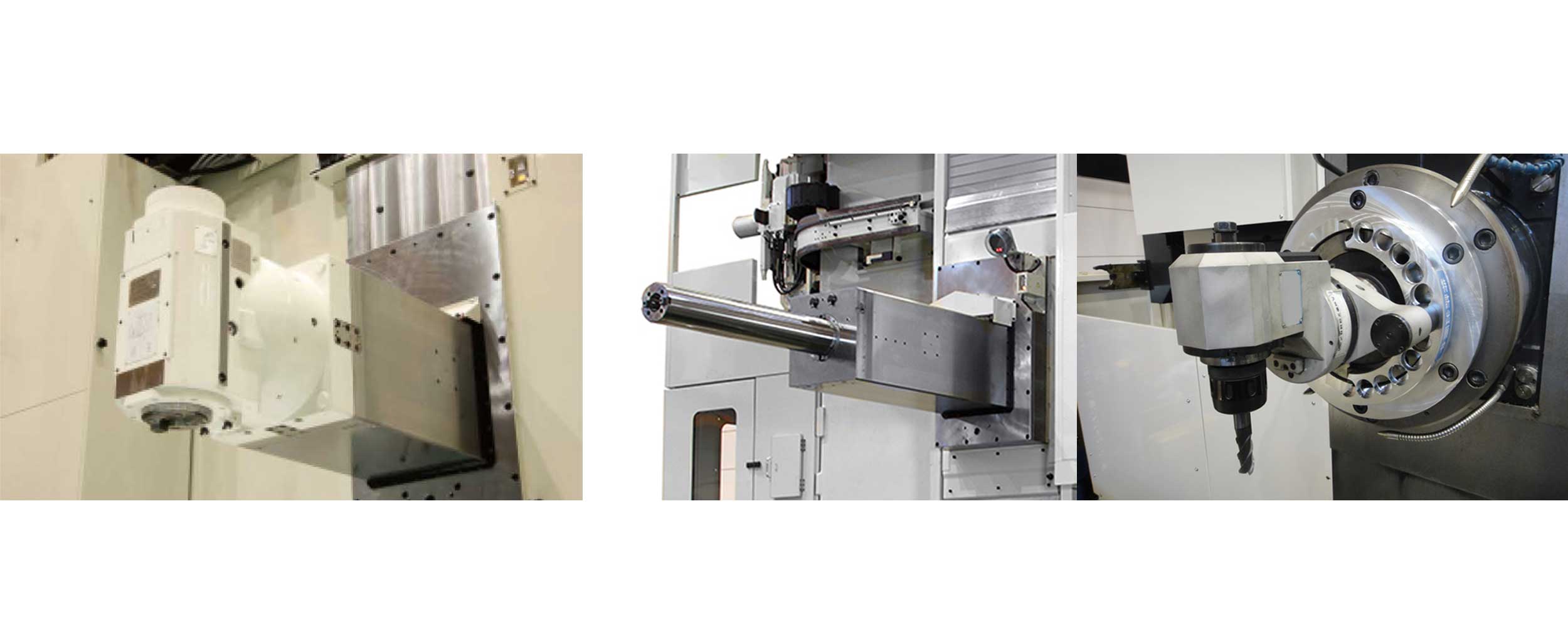

As a machine tool operator, you know that there are many challenges involved in performing precision cutting, drilling, and other operations. Machining complex workpieces with multiple surfaces often require numerous setups and difficult-to-maneuver manual adjustments. Fortunately, there is a tool that can help you overcome the challenges: the right angle head combined with the automatic tool changer.

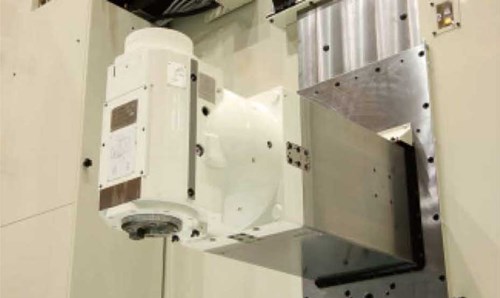

A right-angle head is an attachment that is designed to be used with machine tools. It allows the tool to be oriented at a right angle to the workpiece, making it possible to create complex shapes and contours that would be difficult or impossible to achieve with a conventional tool. With a right-angle head, you can perform the necessary set-up in one continuous application, saving time and improving efficiency.

When pairing the right angle head with the automatic tool changer (ATC), operators can achieve a more streamlined process and increased flexibility.

Save Time Accessing Tight Spaces and Awkward Angles

With a right-angle head and ATC, machine tool operators can perform multiple operations in a single set-up, without the need to stop and change set-ups manually. This can greatly reduce downtime and increase productivity, as the machine can run continuously without interruption. This feature is especially useful for high-volume production runs, where every second counts.

In addition to time savings, this combination can improve the accuracy and precision of the finished product. A right-angle head makes it easier to access these hard-to-reach areas, allowing you to perform precise machining without having to worry about awkward angles or clearance issues. Because you're able to work at more precise angles and with greater accuracy, you can achieve tighter tolerances and smoother finishes. By eliminating the need for manual tool changes with the ATC, the risk of errors or mistakes is also reduced. All of this can lead to more consistent and accurate machining, resulting in a higher-quality end product.

Operators are also more easily able to switch between machining operations without having to stop because the ATC can switch between different tools automatically. This flexibility can be especially useful when working with complex parts that require multiple set-ups to complete.

A Smart Investment in Modern Machining

In modern machining, reducing set-ups and the processing time is crucial to improving productivity and profitability. A right-angle head with an automatic tool changer is a powerful tool that can help customers save time, improve accuracy and precision, and increase flexibility in their operations.

Contact the Machine Tool team to learn more and start incorporating the right-angle head with ATC into your machining operations to streamline processes, reduce set-up times, and increase productivity, ultimately improving your bottom line.

Related Articles View All Machine Tools Articles

Boost Your CNC Machining Confidence: On-Site Training Explained

ELK GROVE VILLAGE, IL, March 7, 2023 - As the manufacturing industry continues to grow and evolve, it's becoming increasingly important for companies to invest in their workforce through proper training programs.In the world of machine tools, on-site train...

Read moreMachine Tool Automation Options for Shibaura Machine's TMD Series

ELK GROVE VILLAGE, IL, February 28, 2023 - Efficiency and productivity are critical factors for success in today's fast-paced manufacturing industry. To maintain a competitive edge, manufacturers must continually seek new ways to optimize their processes a...

Read moreCritical Factors to Consider With Your Machine Tool Foundation

ELK GROVE VILLAGE, IL, February 15, 2023 - Machine tools are the backbone of the modern manufacturing industry and play a critical role in the production of goods and services. While the machine tools themselves are the main focus, their foundation is a cr...

Read morePolar Coordinate Interpolation: Unlocking New Possibilities with Shibaura Machine Tools

ELK GROVE VILLAGE, IL, February 7, 2023 - Have you ever felt like your machining operations were stuck in a straight line? Polar Coordinate Interpolation may be the answer you've been searching for. With this motion control method, you can upgrade your mac...

Read moreMaking Sense of Machine Tool Thread Milling for Your Application

ELK GROVE VILLAGE, IL, January 30, 2023 - When it comes to adding threads to a workpiece, the choice of method can make a significant difference to the outcome. For parts made from difficult-to-machine materials, thread mills have become an increasingly po...

Read moreSupporting Success: Shibaura Machine Tools' Growing Commitment to Customers

ELK GROVE VILLAGE, IL, January 25, 2023 - When purchasing a machine tool from Shibaura Machine, you can expect high-performing equipment. Customer satisfaction is our top priority, and we go above and beyond to ensure that our customers receive the best se...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools