Shibaura Machine Simplifies Lights-Out Molding

ELK GROVE VILLAGE, IL, July 21, 2021 - Amid a shortage of skilled labor and increasingly high offshoring costs, lights-out technology has become a popular topic of conversation amongst injection molding manufacturers.

Lights-out injection molding has impacted plastics manufacturers tremendously. This capability allows American manufacturers a way to create cost, quality, and time efficiencies which they can pass on to their customers and remain competitive. In most cases, it requires less workers during the day and minimal (or zero) workers required on nights and weekends, while production continues on.

Making Lights-Out Injection Molding Easier

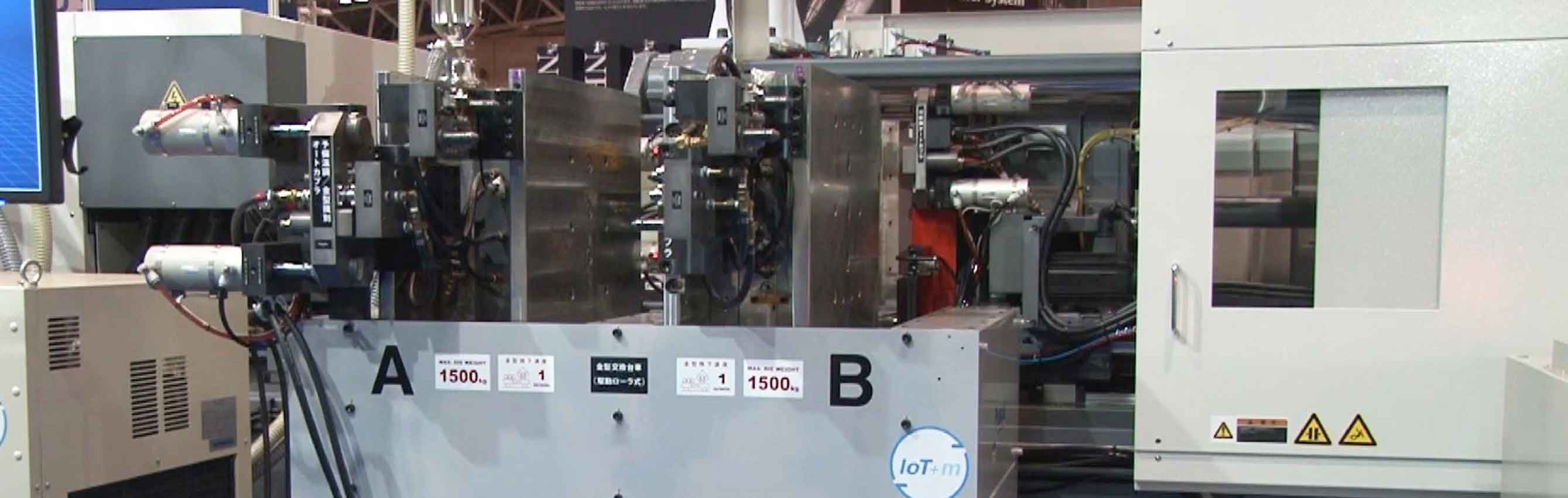

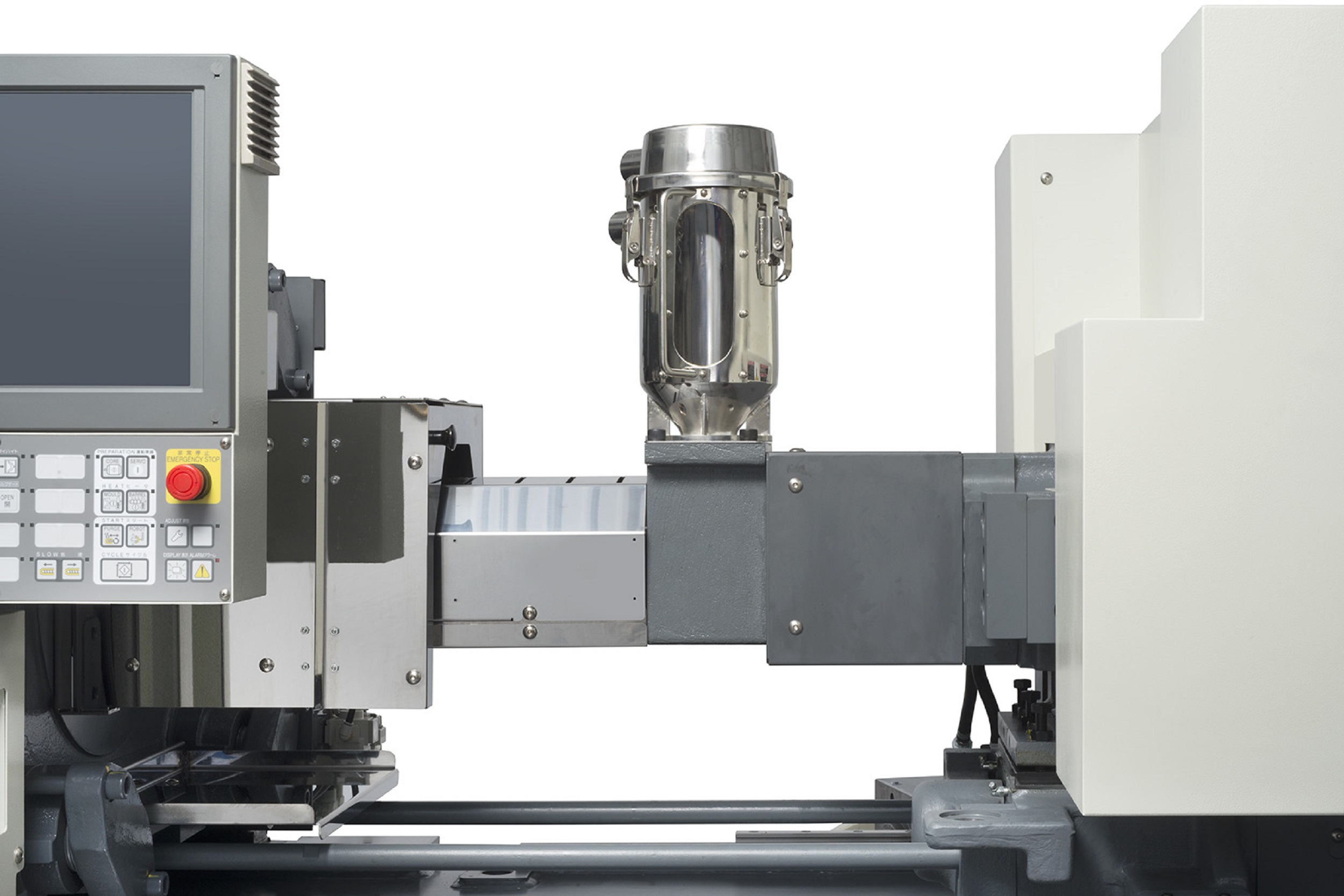

Having the right systems and processes in place is key to being successful with lights-out injection molding. Shibaura Machine is committed to helping innovative manufacturers forge a path into the future, no matter how complex their parts production is. The SXIII injection molding machine offers three important features that aid in automation efforts to run lights-out.

- Manned and Unmanned Mode

As implied, these two modes can be used when staff is or is not present. MANNED Mode is put on when workers are available to respond to the machine in the event of a stoppage. UNMANNED Mode can be used during lights-out and when workers are not present. UNMANNED Mode will react to machine stoppages and alarms by opening the clamp, backing out the injection unit, and shutting off the barrel heats.

- Programmable Outputs

The SXIII comes standard with six programmable outputs and additional outputs can be added as needed. Factories can use the machine's programmable outputs to connect them to auxiliary devices and shut them down in the event of an alarm or stoppage.

- Real Time Machine Monitoring

With the machine being left unattended, it is important that part quality doesn’t suffer. The monitoring trends feature allows the machine to track quality of parts. If a set number of defects are produced, the machine can be triggered to shut down.

In addition to these three standard features, the iPAQET remote monitoring software can be added for additional lights-out support. iPAQET not only gives the user real-time machine status, but also access to all the processing data and the V70 controller from anywhere (setting changes can be made remotely). Email or text notifications for machine alarms or stoppages can also be set-up through iPAQET.

Become a Lights-Out Operation

Is your factory working towards lights-out? Our team at Shibaura Machine welcomes the opportunity to discuss with you how the SXIII can help you meet your production goals.

Contact us today to learn how our ECSXIII series can help your molding operation run lights out!

Related Articles View All Articles

5 Ways to Reduce Injection Molding Start-Up Scrap with Shibaura Machine’s ECSXIII Series

ELK GROVE VILLAGE, IL, July 15, 2021 - When it comes to improving your injection molding process, reducing scrap at machine start-up is one of the more effective ways to increase efficiency. With costs rising on materials and shortages throughout the indus...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

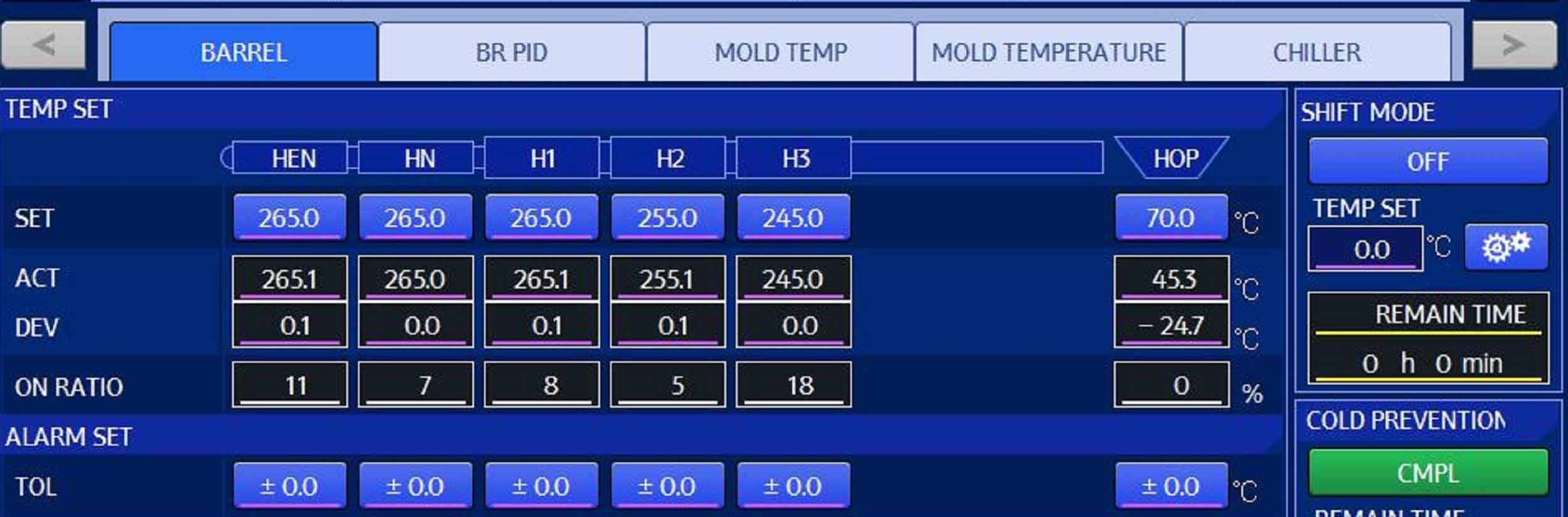

Read moreGain Control Over Your Barrel Temperature with Shibaura Machine’s V70 Controller

ELK GROVE VILLAGE, IL, June 25, 2021 - Errors in temperature control result in a large part of rejects in the injection molding world. If a molder wants to ensure a stable molding cycle and high quality product, having a temperature control process is esse...

Read moreUsing Auto-Purge to Improve Injection Molding Efficiency

ELK GROVE VILLAGE, IL, June 23, 2021 - Molders today are always looking for a way to minimize their losses. So while purging is often necessary, it makes many molders cringe because this process often means costly waste and lost production time- defeating...

Read moreMold Recipe Management: Saving Time and Money in Injection Molding

ELK GROVE VILLAGE, IL, June 9, 2021 - Think of a chef on a Friday night at a popular restaurant. They are tasked with switching from one recipe to the next in a single night. Not only that, they need to make sure they use the correct measurements, with qui...

Read moreInjection Molding Production Management Made Easy

ELK GROVE VILLAGE, IL, June 4, 2021 - Does your injection molding machine offer easy to use onboard production management tools?Many injection molding machines lack user-friendly onboard production management functions. A quality production management tool...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools