Two-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it allows for increased versatility while being simpler and more cost effective in comparison to other processes.

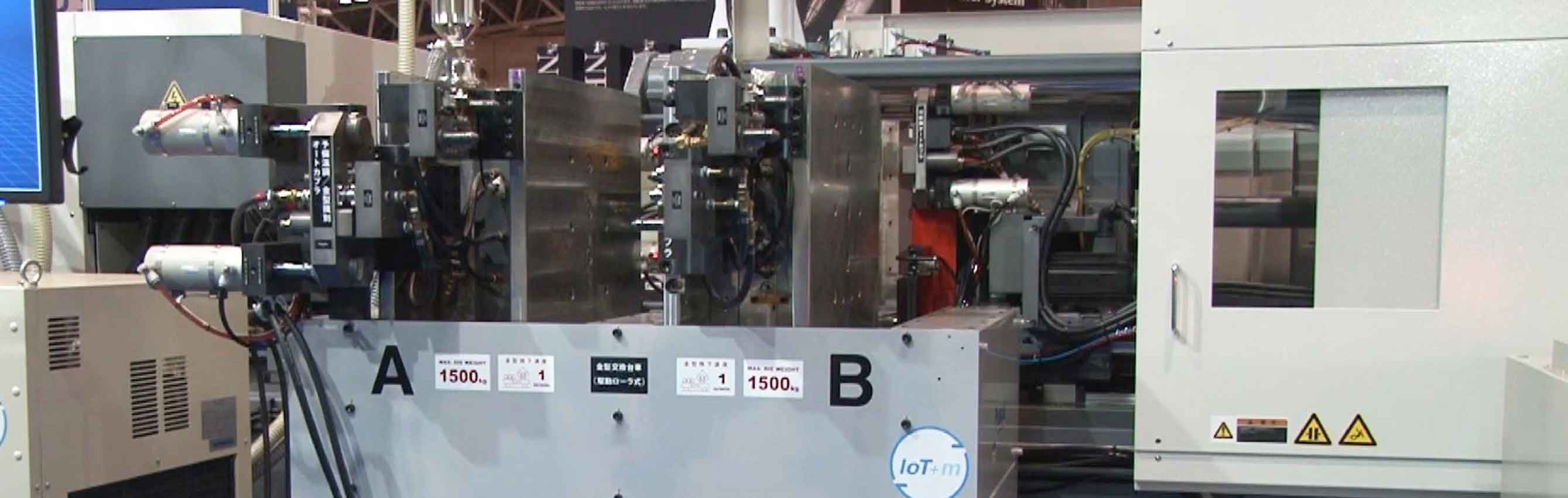

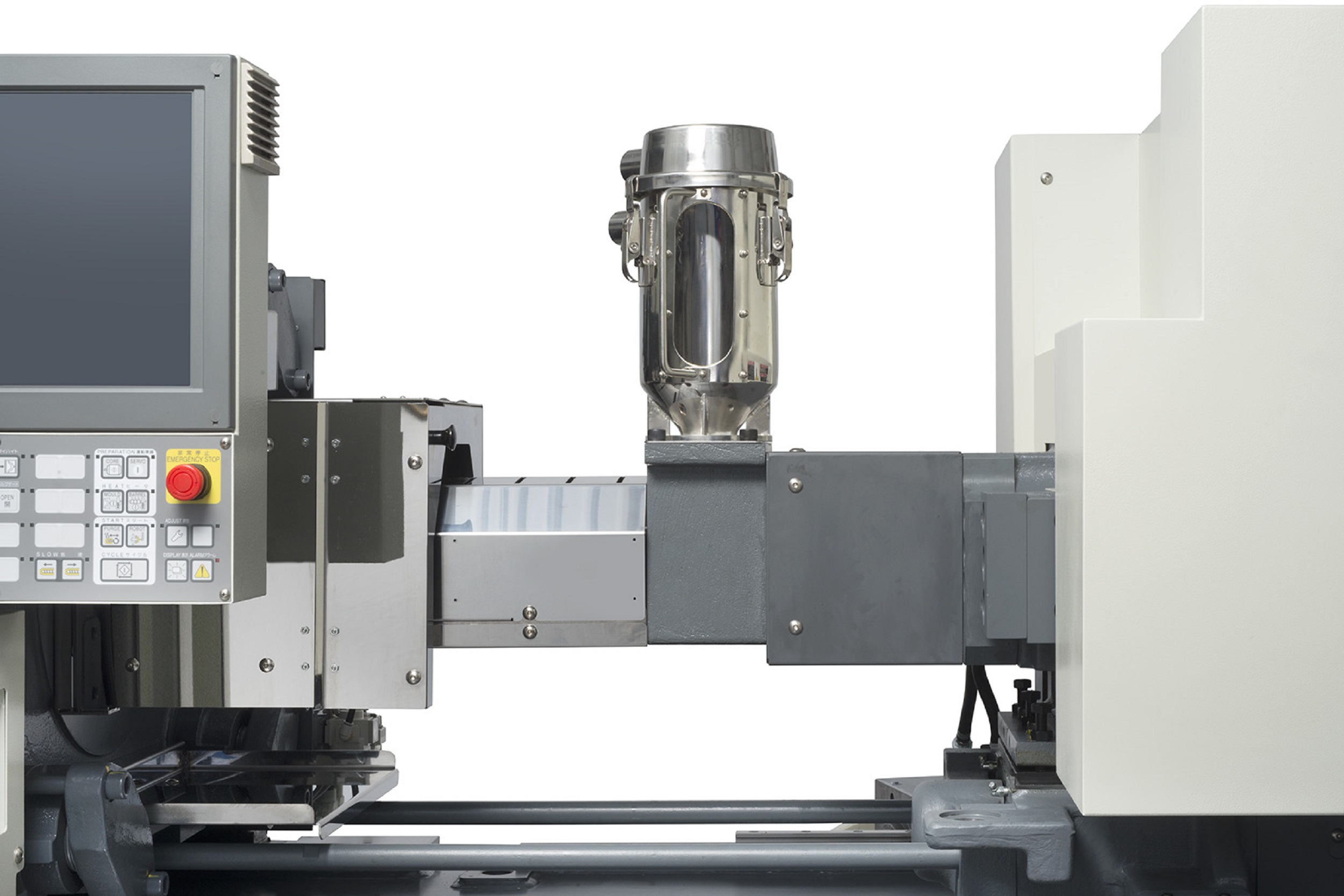

Many manufacturers find themselves wanting to utilize two-shot molding, but without the space or capital to invest in another injection molding machine with this capability. Shibaura Machine offers customers the ability to transform a standard Shibaura Machine into a two-shot system with the E-Multi 2 Shot System. The E-Multi 2 Shot System offers a cost-effective way for Shibaura Machine customers to gain the benefits of two-shot molding while also keeping the ability to switch back to their standard machine to run their conventional molded products when needed.

Two-Shot Molding When You Need It

The options available on the E-Multi 2 Shot System make it easy to optimize production. With many units running in the field for years with this system, it has been proven successful on numerous high performance applications.

Additional key features include:

- All electric servo driven for high performance and precise control

- Flexible configuration options for any application and can be moved from machine to machine (interface via Euromap67 / Euromap12)

- E-Multi System is multifunctional and can also include:

- TempMaster HR Controls (up to 36 zones and more on request)

- Valve gates (2 standard, up to 12)

- Other servo motions (i.e. For Index plates, E-Drive, and Rotary Tables)

Support You Can Count On

During a time when many manufacturers are experiencing limited resources and cost-cutting, budgets for new equipment may also be limited. Shibaura Machine is committed to offering our customers solutions to continue to design and develop new products and expand their footprint through cost-effective options that make sense. Contact our injection molding team today to learn more about how the E-Multi System can help with your next project.

Contact us today to learn more abut our flexible, 2-shot capability!

Related Articles View All Articles

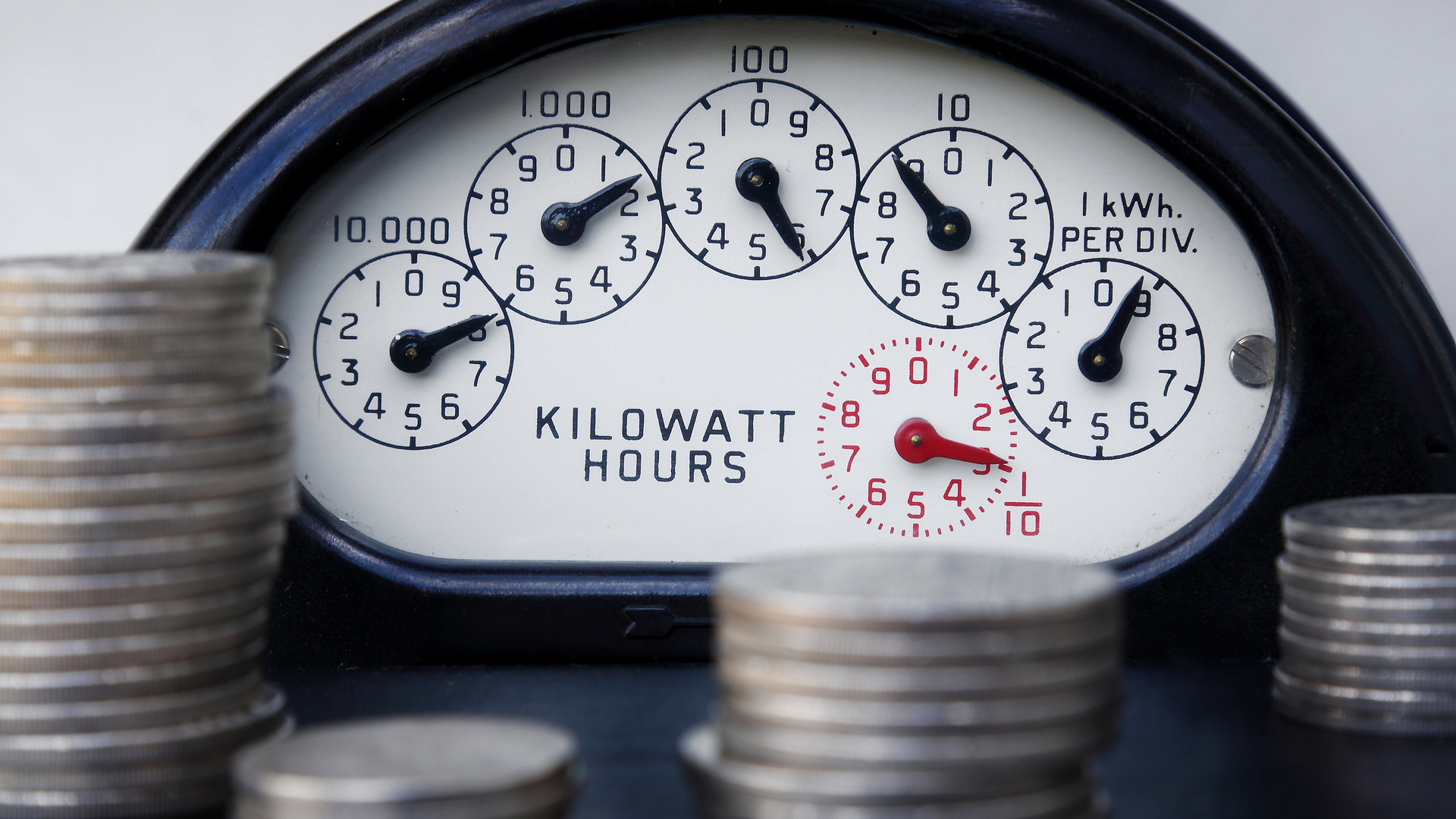

Injection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreShibaura Machine Simplifies Lights-Out Molding

ELK GROVE VILLAGE, IL, July 21, 2021 - Amid a shortage of skilled labor and increasingly high offshoring costs, lights-out technology has become a popular topic of conversation amongst injection molding manufacturers. Lights-out injection molding has impac...

Read more5 Ways to Reduce Injection Molding Start-Up Scrap with Shibaura Machine’s ECSXIII Series

ELK GROVE VILLAGE, IL, July 15, 2021 - When it comes to improving your injection molding process, reducing scrap at machine start-up is one of the more effective ways to increase efficiency. With costs rising on materials and shortages throughout the indus...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

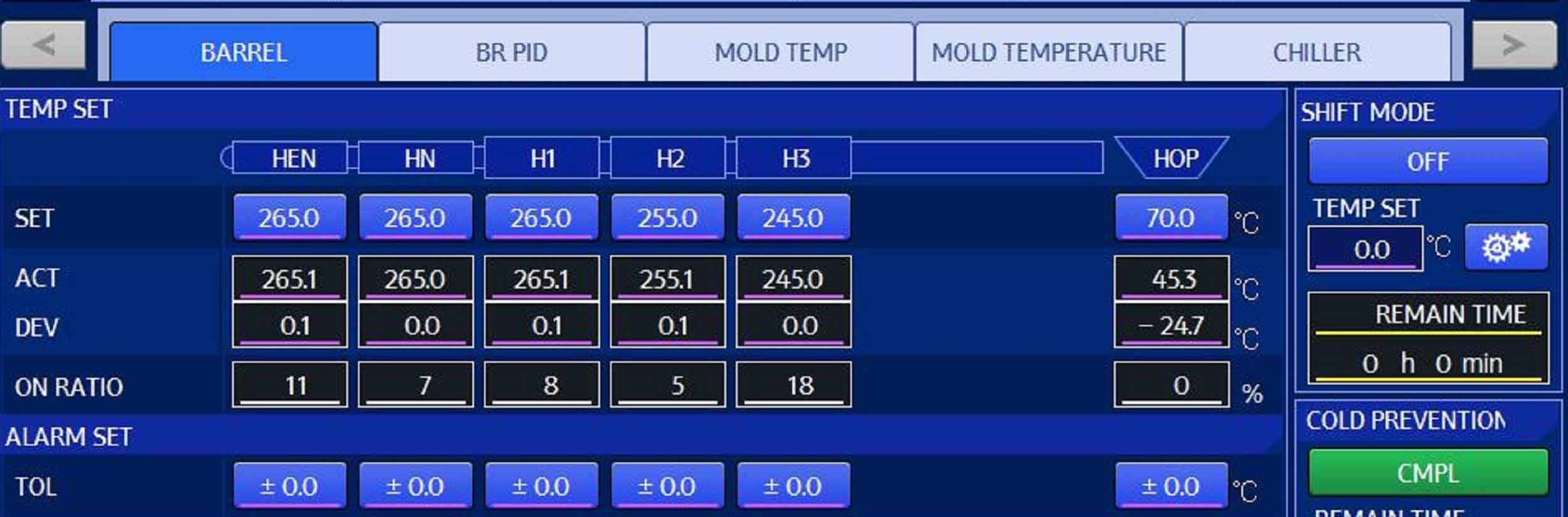

Read moreGain Control Over Your Barrel Temperature with Shibaura Machine’s V70 Controller

ELK GROVE VILLAGE, IL, June 25, 2021 - Errors in temperature control result in a large part of rejects in the injection molding world. If a molder wants to ensure a stable molding cycle and high quality product, having a temperature control process is esse...

Read moreUsing Auto-Purge to Improve Injection Molding Efficiency

ELK GROVE VILLAGE, IL, June 23, 2021 - Molders today are always looking for a way to minimize their losses. So while purging is often necessary, it makes many molders cringe because this process often means costly waste and lost production time- defeating...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools