Shibaura Machine Inspection Testing Checklist for Machine Tools

ELK GROVE VILLAGE, IL, June 22, 2021

Whether your goal is to produce small or large parts, you will want to make sure you are purchasing a machine tool from a builder that has a strong quality initiative and can meet your customers requirements whether the builder is offering you a lower total cost of ownership or high return on investment. Having a manufacturer like Shibaura Machine who takes care in verifying the quality of the machine tool during the assembly of the machine is an important consideration to ensure all of these expectations are met.

Shibaura Machine has set forth specific inspection criteria that each machine tool must pass before the machine tool is shipped from the factory and turned over to its new owner. This time tested criteria has been used on thousands of machine tools worldwide giving our customers the peace of mind that they are getting the machine tool quality they expect.

Inspection Tests for Machine Tools

Shibaura Machine’s inspection criteria ensures your new machine tool is operating at top performance and reliability.

Specification Test

During this test sequence all machine mechanical and electrical specifications, CNC control and optional equipment specifications are verified and documented against the machine build specification.

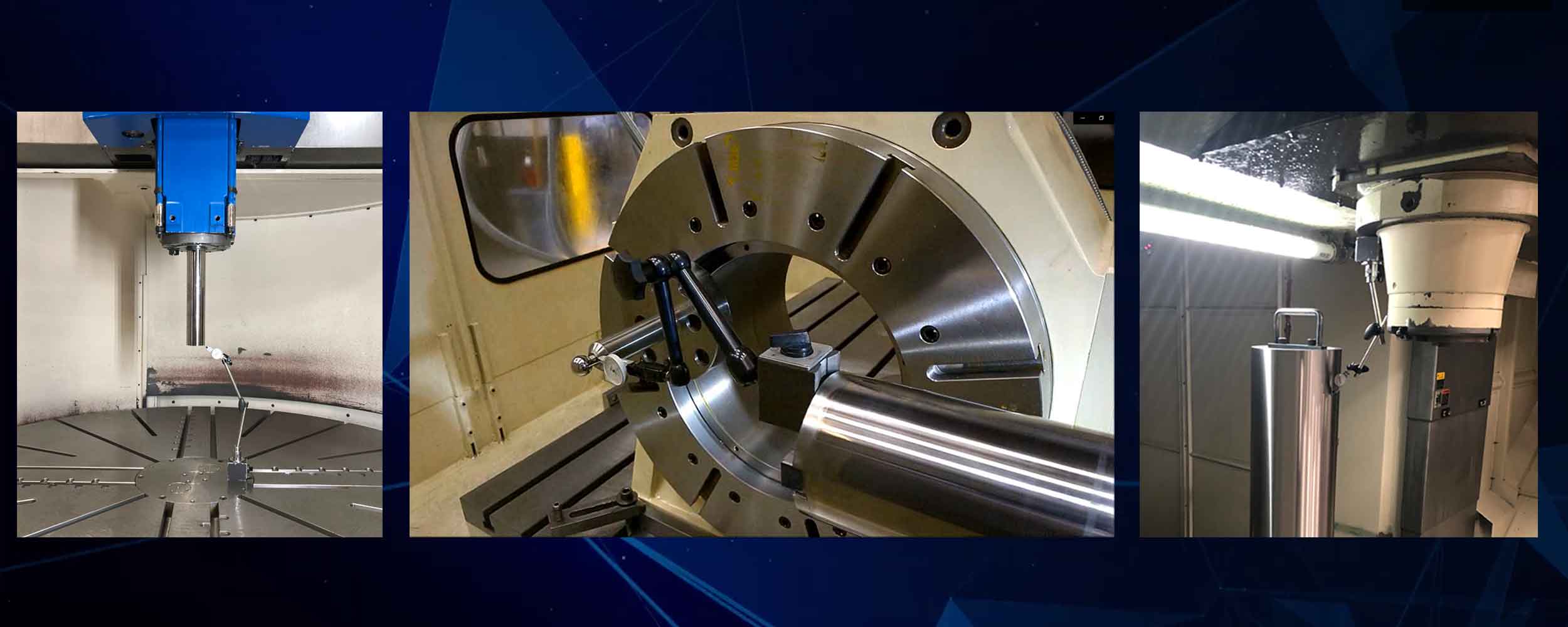

Functionality Test

The series of functional testing includes checking the operation of the machine spindle and axes under cutting and non cutting conditions. All CNC control features are verified during the functionality tests.

Accuracy Test

Being able to complete the most exacting requirements to produce high quality products requires high machine accuracy. Here are the following accuracy tests that we do before shipment.

- Static accuracy test: Verifying the relationships of all the axes in a series of machine alignment checks.

- Positioning and repeatability accuracy inspection: Verifying positional and repeatability accuracy relationships between linear and rotary axes

- Machining accuracy tests: 5 unique machine cutting tests are done to verify machining accuracy

Changing the Standard in Machine Tools

With proven machine tool inspection criteria, Shibaura Machine reinforces its commitment to providing our customers with optimum performance. Contact the machine tool team today to learn more about our inspection criteria at MT-Sales@shibaura-machine.com.

Learn more about our machine models.

Related Articles View All Machine Tools Articles

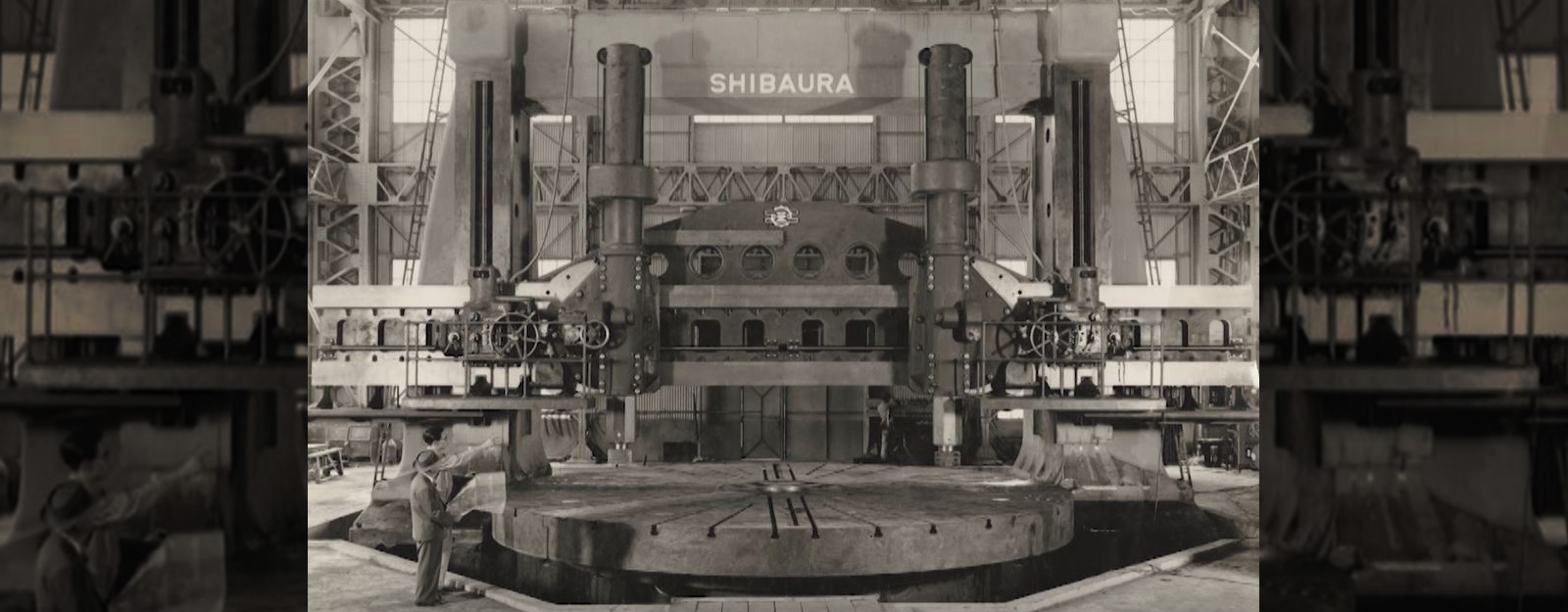

Shibaura Machine is Celebrating 145 Years of Changing the Standard in Machine Tools

ELK GROVE VILLAGE, IL, May 18, 2021 - The year 1876 had a lot of milestones. The United States celebrated the 100th anniversary of the Declaration of Independence, the telephone patent was issued to Alexander Graham Bell, and that is when Shibaura Machine ...

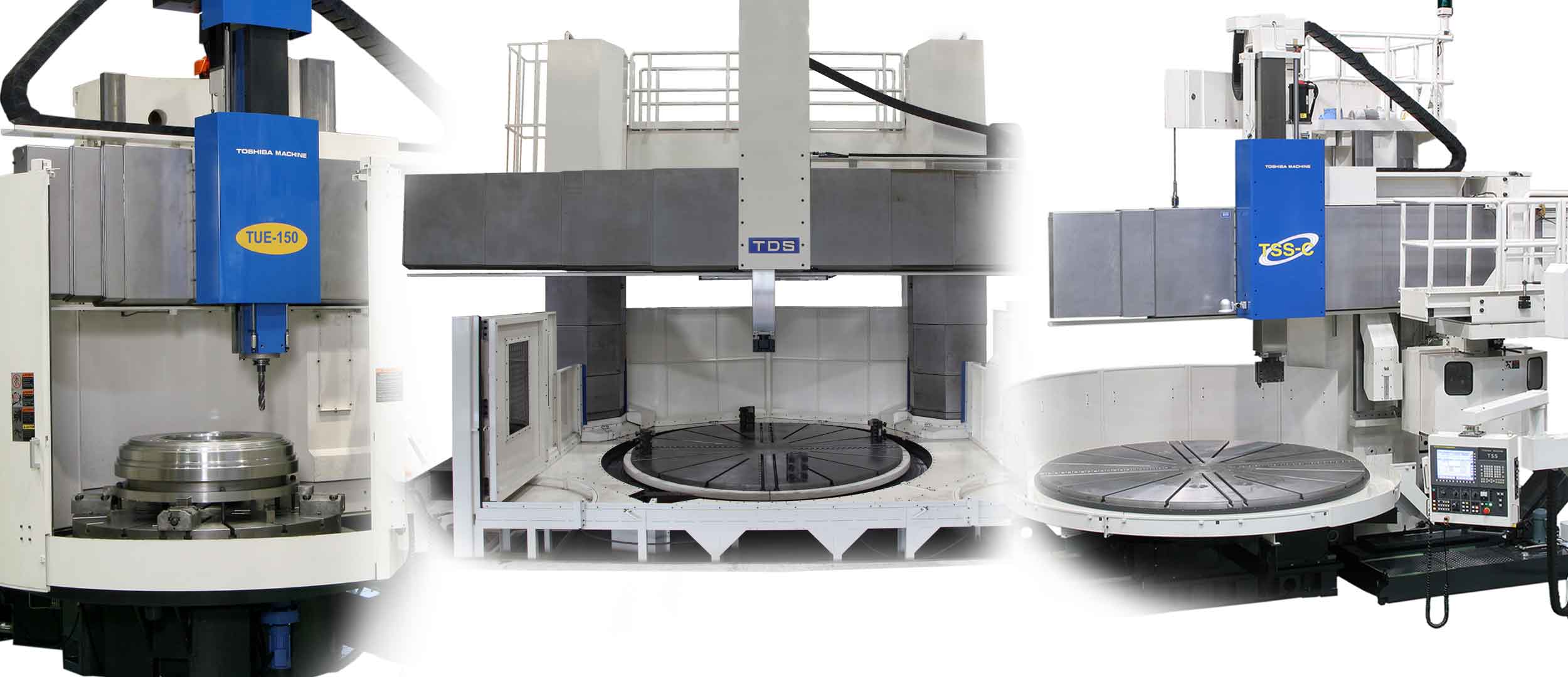

Read moreShibaura Machine’s Vertical Turning Lathes Line Up: Strong, Rigid, and Flexible

ELK GROVE VILLAGE, IL, May 10, 2021The advantages and possibilities of vertical turning lathes (VTLs) are enormous. While their counterparts the horizontal lathes might be better known, the VTL has evolved to become a powerhouse. Incorporating not only man...

Read moreThe Shibaura Machine Milling Machine Guide

ELK GROVE VILLAGE, IL, May 3, 2021Maximizing productivity and getting the most value out of your milling machine investment is key whether you are a large manufacturing operation or smaller job shop. Making sure you are investing in not only high quality c...

Read moreHave You Considered Your Machine Tool DNA from Mother Machines to Nano Machines?

ELK GROVE VILLAGE, IL, April 26, 2021A machine to make other machines possible. Any guesses on what that machine might be?From machining components for the largest airplanes, ships, trains, and even the largest earth moving equipment in the world, the mac...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools