Shibaura Machine Horizontal Spindle Quill Machines Bring Power and Versatility to Shop Floors

ELK GROVE VILLAGE, IL, July 12, 2021

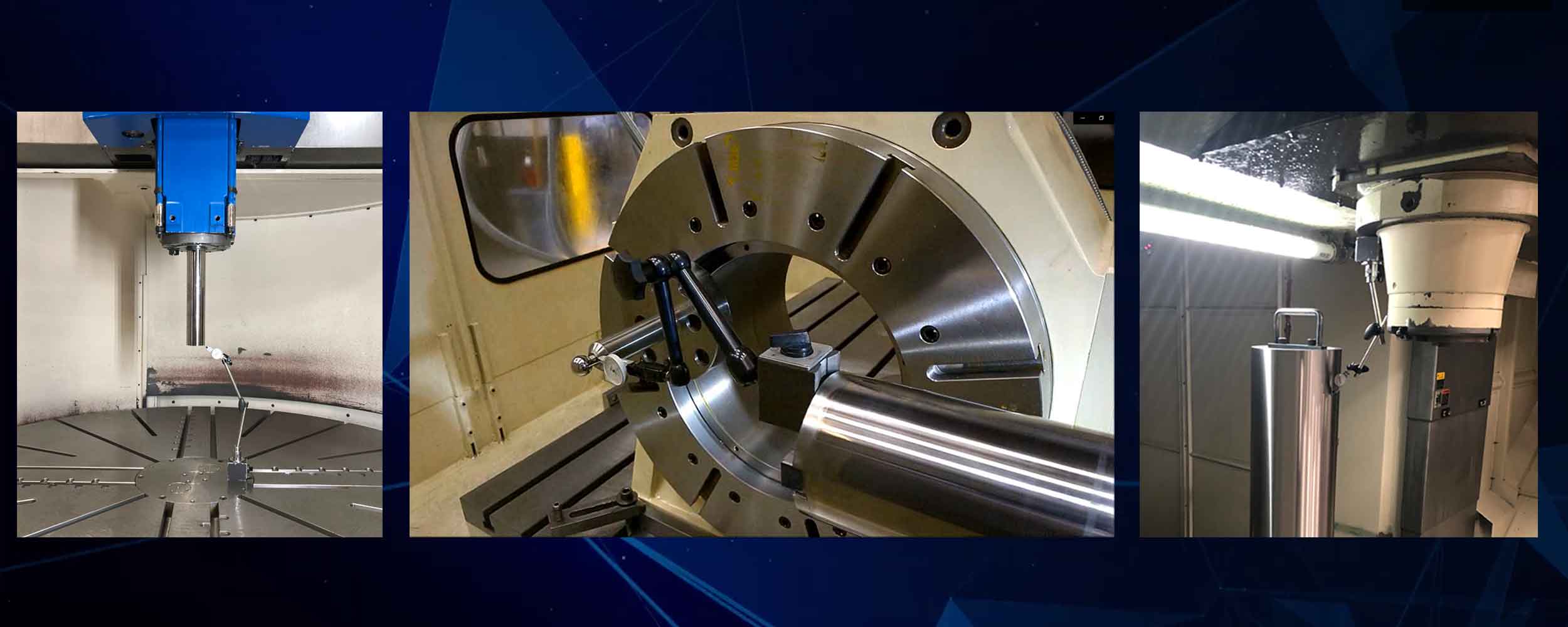

Spindles continue to play an important role in a fast production space. Horizontal spindle quill machines allow shops to take on complex cutting jobs and also combine the structural stability and geometric precision for enhanced performance reliability.

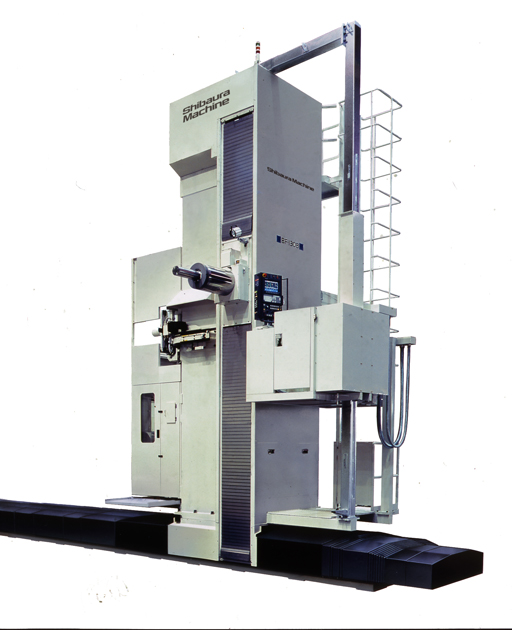

Over the past 47 years, Shibaura Machine has manufactured 1000’s of Horizontal Boring Machines (HBM) utilizing both column or ram axis (Z) and a quill/bar axis (W). The system was designed to increase efficiency and versatility of large-part machining. These machines stand out from the rest with construction that allows them to machine surfaces smoothly and optimally. Their flexibility allows shops to innovate and increase production– with the reliability of the Shibaura Machine name.

Designed With the Machinist in Mind

The quill/bar axis from Shibaura Machine demonstrates maximum power and versatility. With the Z/W tracking of tool point position, users can easily verify tool point position regardless of quill or column position. It also offers an extended reach of tool point without sacrificing positional accuracy of the machine without additional tool joints and offers the ability to utilize Tool Center Point Control (TCP) in 5 axis machines. If you have a machining application that requires longer tool reaches, why not use the quill instead of longer tool lengths?

Shibaura Machine offers an extended range of quill/bar diameters (110mm, 130mm, 150mm, 160mm and 180mm diameter) and operators may choose to use spindle attachments such as U axis that utilize bar extension to mechanically move the position of U axis tool point or other attachments requiring activation by a quill/bar.

An extended range of the workpiece probing capability is available with various workpiece probe cycles and rotary axis tracking for multi surface machining is accomplished with quill extension.

Take on Complexity

Tackle complex production jobs with ease by utilizing the quill/bar axis capability. Shibaura Machine offers the quill/bar axis capability on the following machines:

- Series BTH- Table-type horizontal boring and milling machines

- Series BP- Planer-type horizontal boring and milling machine with rotary table

- Series BSF- Floor type horizontal milling and boring machine

- Series BF- Floor type horizontal milling and boring machine

Contact the CNC Machine Tool team to learn more at MT-Sales@shibaura-machine.com.

Learn more about our machine models.

Related Articles View All Machine Tools Articles

Aviation Industry Post Pandemic Update for Manufacturers

ELK GROVE VILLAGE, IL, July 6, 2021The modern aviation industry is slowly seeing positive growth for the first time since the COVID-19 pandemic hit. United Airlines announced in late June they will post a positive income for the first time since January 20...

Read moreThe Benefits of 5 axis 3+2 Machining with Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2021Looking into 5 axis machining? It’s gaining a lot of attention today and for good reason. However, if your shop is considering a move to a 5 axis machine you should also read up on 3+2 machining. Most machining applicati...

Read moreMaximize Speed and Maintain Control with Tosnuc CNC Shape feature

ELK GROVE VILLAGE, IL, March 1, 2021 When purchasing a new CNC Machine Tool many customers find themselves still not being able to machine complex workpieces as fast as needed due to inconsistent feedrates or tool chip loads. Shibaura Machine has now dev...

Read moreShibaura Machine Inspection Testing Checklist for Machine Tools

ELK GROVE VILLAGE, IL, June 22, 2021Whether your goal is to produce small or large parts, you will want to make sure you are purchasing a machine tool from a builder that has a strong quality initiative and can meet your customers requirements whether the ...

Read moreThe Shibaura Machine Milling Machine Guide

ELK GROVE VILLAGE, IL, May 3, 2021Maximizing productivity and getting the most value out of your milling machine investment is key whether you are a large manufacturing operation or smaller job shop. Making sure you are investing in not only high quality c...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools