What to Consider When Calculating Machine Tool Total Cost of Ownership

ELK GROVE VILLAGE, IL, October 19, 2021 -

Manufacturers everywhere are feeling the pressure to reduce operating costs. Understanding the true total cost of ownership (TCO) of your machine tool will allow you to make a more informed decision and better evaluate the true value and cost.

Having worked with thousands of shops going through the purchasing process, Shibaura Machine Company, America is able to assist owners in calculating the TCO. The most successful machine tool purchase decisions take into consideration not only initial machine and variable costs.

Calculating Machine Tool Total Cost of Ownership

Understanding all factors can not only enable you to purchase the right machine tool but also make an immediate difference on revenue earned on each job from day one.

Upfront costs

- Machine

- Automation

- Tooling and fixturing

- Facility preparation

After purchase costs

In order to truly compete in a global market, you will want to look beyond initial upfront costs to the accumulated after purchase lifetime machine costs.

- Machine operator

- Programmer

- Utilities

- Depreciation/resale value

- Operator and maintenance staff training

- Workpiece material

- Perishable tooling

- Machine maintenance *

*Shibaura Machine Company, America customers find that their costs are less when compared to competitor machines due to the quality of the Shibaura Machine products.

What is Your TCO?

Shibaura Machine Company, America understands that purchasing a machine tool is not a small decision. It is one that will significantly impact your shop's profitability. Our team can assist owners to understand the true TCO, from up-front costs to after-purchase cost considerations. Contact our machine tool sales team to learn more MT-Sales@shibaura-machine.com

Related Articles View All Machine Tools Articles

CNC Machine Tool Preventive Maintenance Tips

ELK GROVE VILLAGE, IL, October 11, 2021 - Optimizing machine tool performance and uptime starts with a healthy machine. Preventive maintenance not only protects your investment and improves machine tool longevity, but also keeps machining processes capable...

Read moreShibaura Machine’s Checklist for a Successful Machine Tool Installation

ELK GROVE VILLAGE, IL, October 04, 2021 - High quality machine tools will last for years, so for many shops it may have been awhile since their last installation. The prep before and set-up of your CNC machine is important to make sure it can do its job pr...

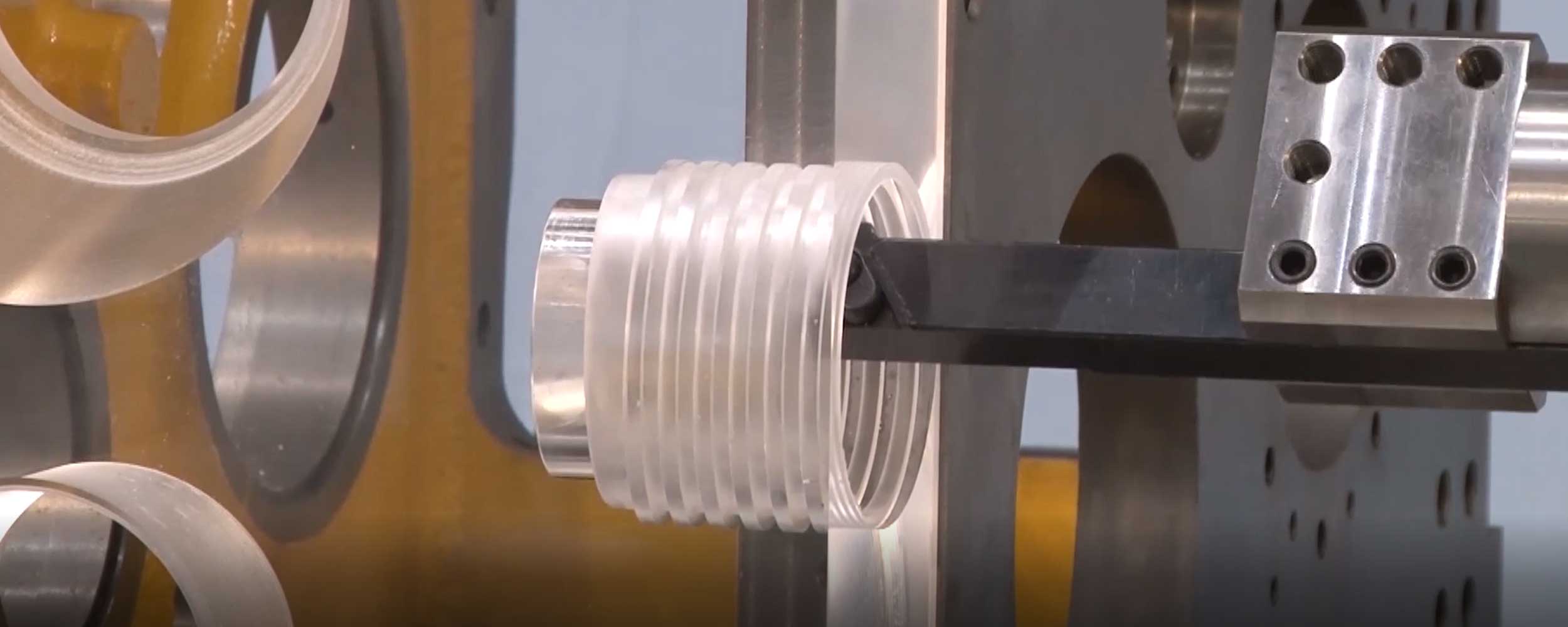

Read moreShibaura Machine’s Quill Machining Strategy Provides Performance and Cost Advantage

ELK GROVE VILLAGE, IL, September 21, 2021When it comes to obtaining the highest level of profitability in CNC shops, many go on the hunt for different technologies, tools, and processes. Often overlooked is quill (bar) style horizontal machining. Quills ha...

Read moreEnhance Versatility with Shibaura Machine’s Orbit Boring Function

ELK GROVE VILLAGE, IL, September 14, 2021Whether your shop has high speed finishing or heavy duty machining applications, orbit boring is worth a consideration. With Shibaura Machine’s orbit boring function you can not only remove metal faster, but it is w...

Read moreShibaura Machine Discusses Opportunities to Improve Machine Tool OEE

ELK GROVE VILLAGE, IL, September 7, 2021How many times is your machine “getting it right the first time” compared to what it should be producing in a set time? This is the basis of determining Overall Equipment Effectiveness (OEE), a key performance indica...

Read moreOptimize Innovation with Siemens Realize Live Virtual Event

ELK GROVE VILLAGE, IL, August 31, 2021Every industry comes with its own set of unique manufacturing requirements. Whether it be complex shapes, large part sizes, or the use of exotic metals, having partners that provide specific solutions to meet those cha...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools