Adding a Workpiece Inspection Probing System to Your Machine Tool Is Worth Considering

ELK GROVE VILLAGE, IL, November 2, 2021 -

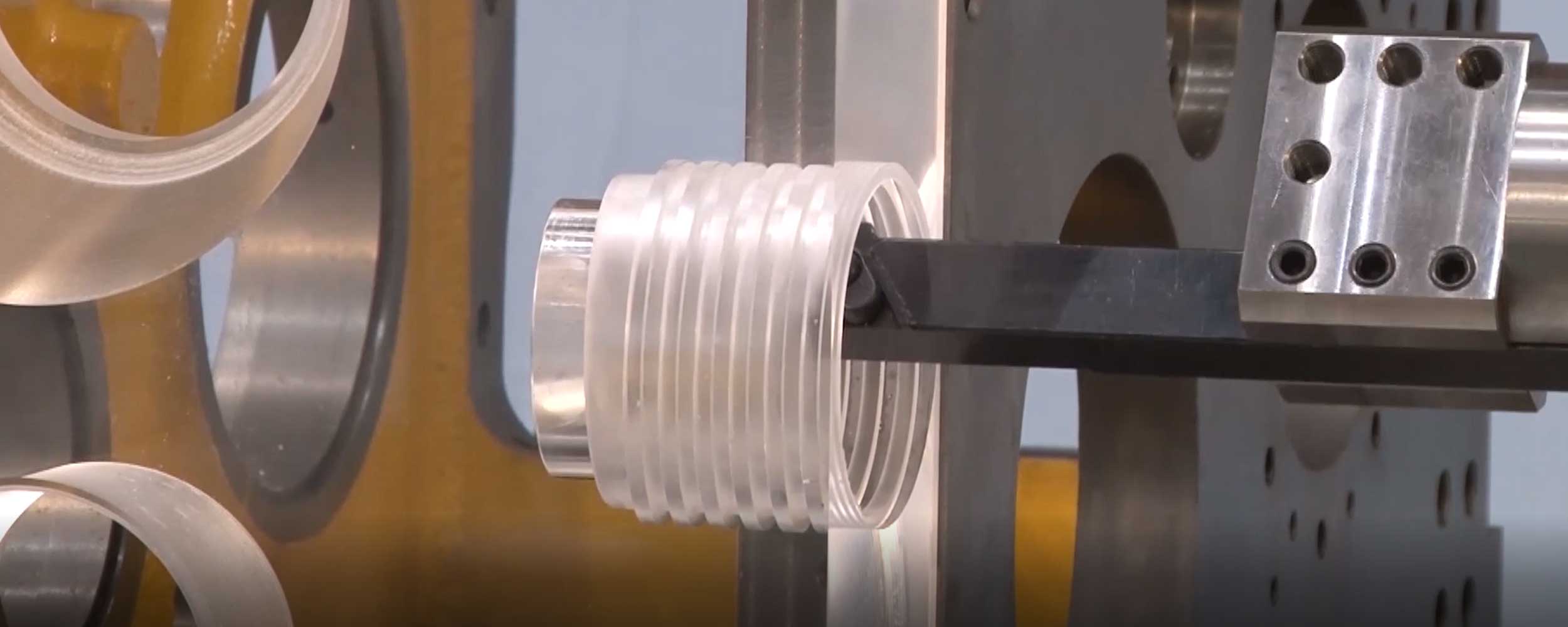

As machine tool automation advances, more manufacturers are looking towards the addition of a inspection probing system to help them make a bigger impact on their performance and profitability.

That is why Shibaura Machine is proud to partner with Metrology Resource Group (MRG) in Rockford, IL to offer the integration and application assistance for our customers to add the Renishaw inspection probe system RPM-60 product to our vertical turning lathe, horizontal boring mill, and bridge style/double column machines.

Cost Savings & Quality Improvements

Smart production environments are quickly evolving. The Renishaw probing systems are industry-leading in technology and performance to allow manufacturers to automate their processes as effectively as possible.

Setting a workpiece prior to machining delivers improvements to performance and profitability throughout industries. Reductions in downtime, scrap/rework, and reducing calibration and maintenance costs are some of the initial benefits Shibaura Machine customers have reported. Due to the automation, errors from manual input are reduced and operators are able to focus on proactive engineering roles. Setting a workpiece prior to the machine also improves the safety of operators because they no longer need to enter the workzone for manual measurements.

Automatic gauging and first-off inspection offer an additional competitive edge. With adaptive machining, you get process feedback to minimize variation, increasing your confidence in unmanned machining. First-off inspection is available with an automatic offset update which reduces machine downtime normally spent waiting on inspection results.

All of these bullets add up to repeatability, process control, and added quality. In turn, a lower overall total cost of ownership and increased competitiveness in the industry is achieved.

Consider Your Application

There is a inspection probe for every application. If your shop floor is looking to improve repeatability, process control, and quality going into 2022, contact our team today to discuss how the addition of a Renishaw tool probing system to your Shibaura Machine Tool can make a positive impact on helping you reach your goals.

Related Articles View All Machine Tools Articles

How Shibaura Machine Builds Quality into Every Machine Tool

ELK GROVE VILLAGE, IL, October 25, 2021 - Building a machine tool from a geometry standpoint can be equated to building a house. Just like a house needs walls to be square, floors to be flat, and structural components need to be aligned the same principles...

Read moreWhat to Consider When Calculating Machine Tool Total Cost of Ownership

ELK GROVE VILLAGE, IL, October 19, 2021 - Manufacturers everywhere are feeling the pressure to reduce operating costs. Understanding the true total cost of ownership (TCO) of your machine tool will allow you to make a more informed decision and better eval...

Read moreCNC Machine Tool Preventive Maintenance Tips

ELK GROVE VILLAGE, IL, October 11, 2021 - Optimizing machine tool performance and uptime starts with a healthy machine. Preventive maintenance not only protects your investment and improves machine tool longevity, but also keeps machining processes capable...

Read moreShibaura Machine’s Checklist for a Successful Machine Tool Installation

ELK GROVE VILLAGE, IL, October 04, 2021 - High quality machine tools will last for years, so for many shops it may have been awhile since their last installation. The prep before and set-up of your CNC machine is important to make sure it can do its job pr...

Read moreShibaura Machine’s Quill Machining Strategy Provides Performance and Cost Advantage

ELK GROVE VILLAGE, IL, September 21, 2021When it comes to obtaining the highest level of profitability in CNC shops, many go on the hunt for different technologies, tools, and processes. Often overlooked is quill (bar) style horizontal machining. Quills ha...

Read moreEnhance Versatility with Shibaura Machine’s Orbit Boring Function

ELK GROVE VILLAGE, IL, September 14, 2021Whether your shop has high speed finishing or heavy duty machining applications, orbit boring is worth a consideration. With Shibaura Machine’s orbit boring function you can not only remove metal faster, but it is w...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools