Saving on Perishable Tool Costs Starts with Machine Tool Quality

ELK GROVE VILLAGE, IL, November 30, 2022 -

Every shop is challenged with ways to maximize revenue while minimizing costs. That is why when you are looking to make an investment on a new machine tool it goes way beyond the initial price tag. With extensive experience in manufacturing and servicing machine tools, Shibaura Machine understands that a fraction of the machine’s overall cost is the initial purchase price and the majority of the investment goes into its lifetime of operation which can greatly impact the bottom line through the years.

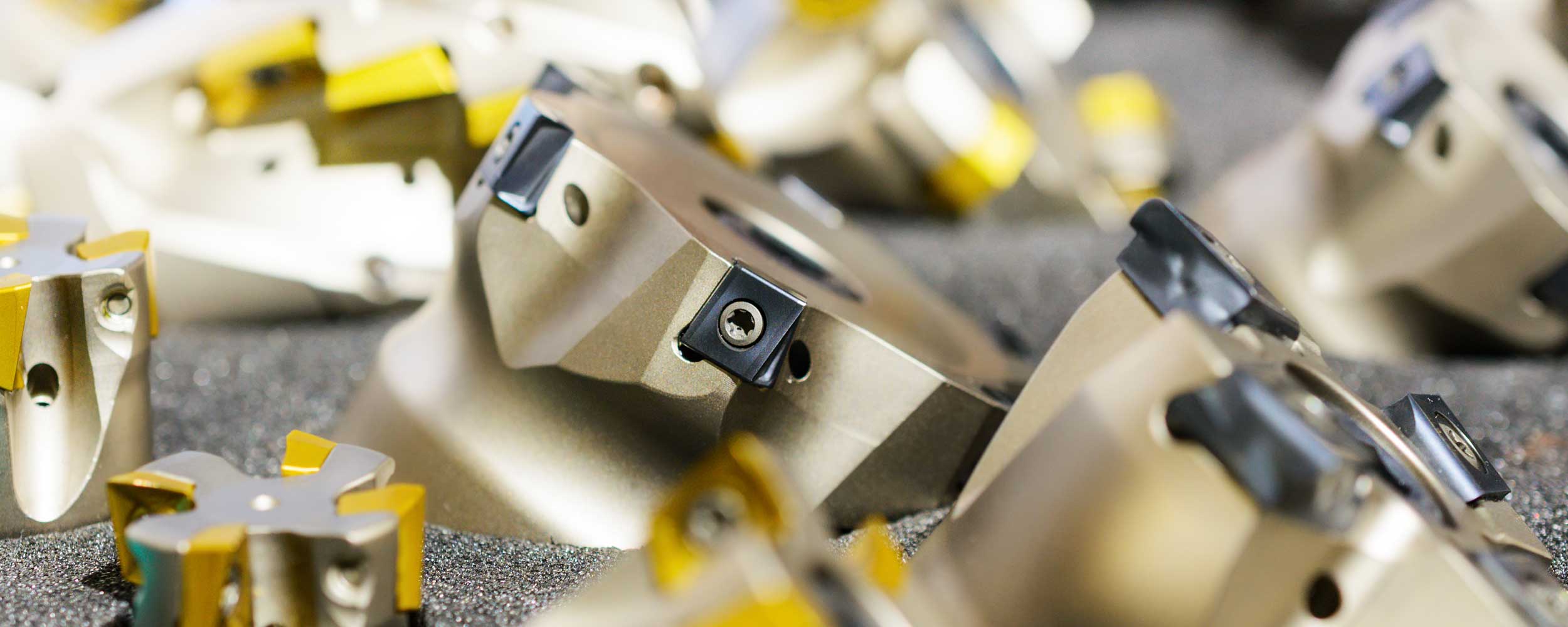

One of the top ongoing financial impacts for any shop to consider is how much is spent each month on perishable tooling for the machine tool. Being able to optimize this recurring cost starts before any workpiece is run through production. At the core, choosing a high-quality machine tool design and construction can reduce your perishable tooling costs which can make a huge difference in your total cost of ownership.

Savings on Perishable Tooling Starts With Machine Tool Quality

The longevity of perishable tools can be improved by a machine tool’s rigidity and damping. A robust, high-quality machine tool that incorporates these two elements will positively impact your shop's recurring tooling cost year after year.

The reason for this is because tool life is heavily impacted by uncontrolled energy at its cutting tip. This energy is often found in the form of vibration, noise, and chatter. Too little stiffness and insufficient damping of a machine tool create a continual uncontrolled energy that wears down perishable tools much quicker then if the energy is able to be subdued.

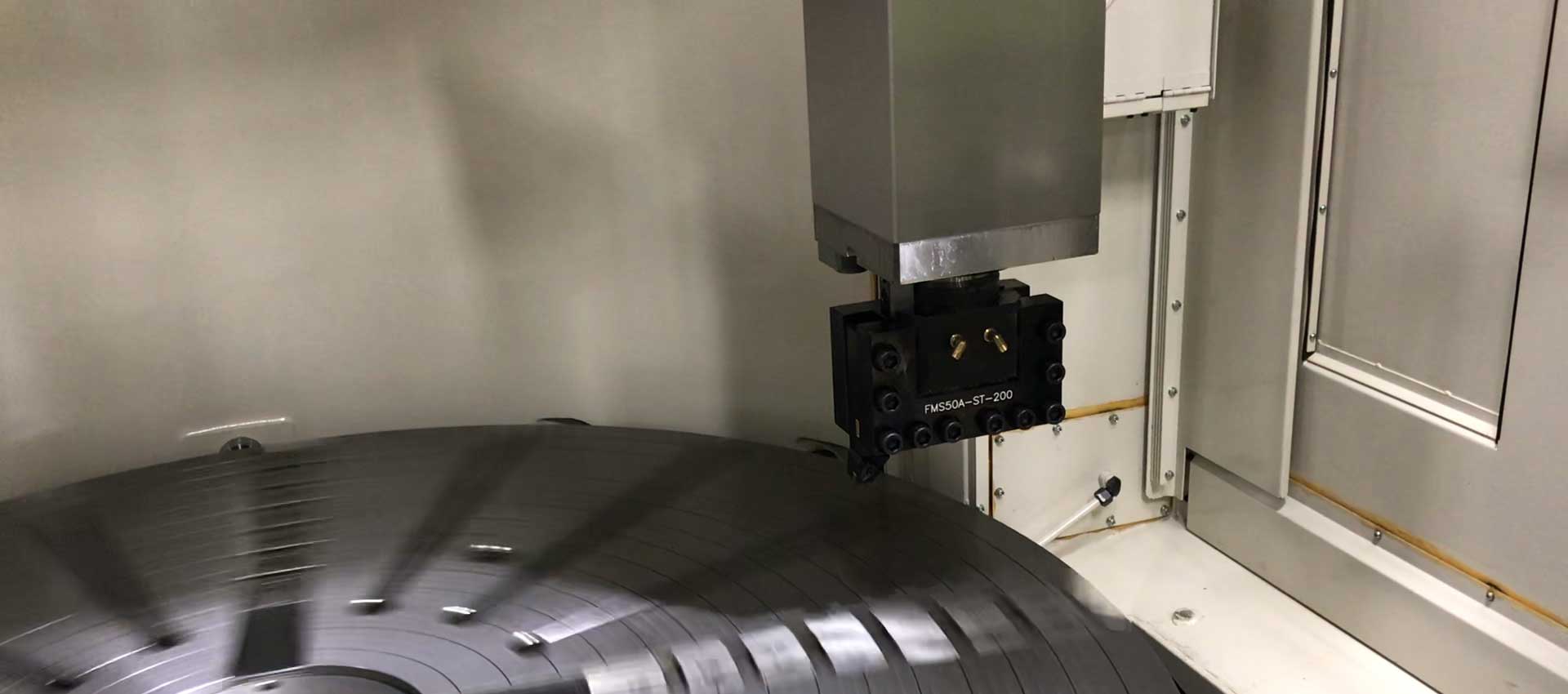

For this reason, Shibaura Machine has designed its machine tools with optimum structural integrity, sourcing all major castings from our own foundry in Japan to further ensure the highest quality. More specifically, using heavy cast iron and precision fitting parts provide high levels of rigidity to improve the stiffness of the system which lessens the vibration in the tool tip. Damping of our machine tools also reduces the magnitude of uncontrolled energy significantly. That is why these two elements alone are extremely important to ensure the machine tool vibration is lessened, which improves part quality and overall tool life.

Start Reducing Overall Tooling Cost

The initial investment of a machine tool by Shibaura Machine will quickly pay for itself when factoring in the accumulated lifetime costs and longevity, equating to a machine tool that ultimately costs less over time.

Contact the Machine Tool Team to learn more today.

Related Articles Articles

Twin Ballscrew Axes Design Offers a High level of Positional Accuracy and Repeatability in Bridge Mill Machine Tool

ELK GROVE VILLAGE, IL, November 22, 2022 - On most milling or turning machine tools, single ballscrew axes designs are used in conjunction with guide surface for table travel, spindle-head travel and column travel. In order to achieve the high repeatabili...

Read moreThree Important Factors to Consider When Choosing a Machine Tool Manufacturer

ELK GROVE VILLAGE, IL, November 15, 2022 - Being able to plan and deliver predictable results is key to maintaining a competitive edge in manufacturing. When it comes to machine tools, the company you choose to purchase from plays a big role in ensuring th...

Read moreThe Shibaura Machine Standard for Tool Holders

ELK GROVE VILLAGE, IL, November 8, 2022 - What to Consider When Choosing a Tool Holder When it comes to machining accuracy of machine tools and product quality, tool holders can be highly influential. Shibaura machine tools are designed to use a high quali...

Read moreImprove Efficiency and Grow Opportunity with a Multi-tasking Machine Tool

ELK GROVE VILLAGE, IL, October 24, 2022 - Being able to combine functions in a single machine tool has long allowed us to save time, save money, and increase efficiency. Everything from smartphones to printers, even gym equipment, has been transformed to p...

Read moreConsiderations when using large cutting tools

ELK GROVE VILLAGE, IL, October 18, 2022 - When searching for the appropriate tooling for your machining application there are many different factors that should be considered. From speeds and feeds to workpiece shape and material, and even how much power d...

Read moreIs High Feed Machining Right for My Shop?

ELK GROVE VILLAGE, IL, October 04, 2022 - Getting parts out the door with the highest efficiency and lowest cost has remained a constant productivity marker for machine tool shops. High feed machining is a process that has been around for a while and when ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools