The Smart Choice for Chip and Coolant Management: Introducing the TUE Series Top Cover

ELK GROVE VILLAGE, IL, May 9, 2023 -

As technology continues to evolve, so do the challenges that arise in the manufacturing industry. One of the challenges that persist is managing coolant and chips in the machining process.

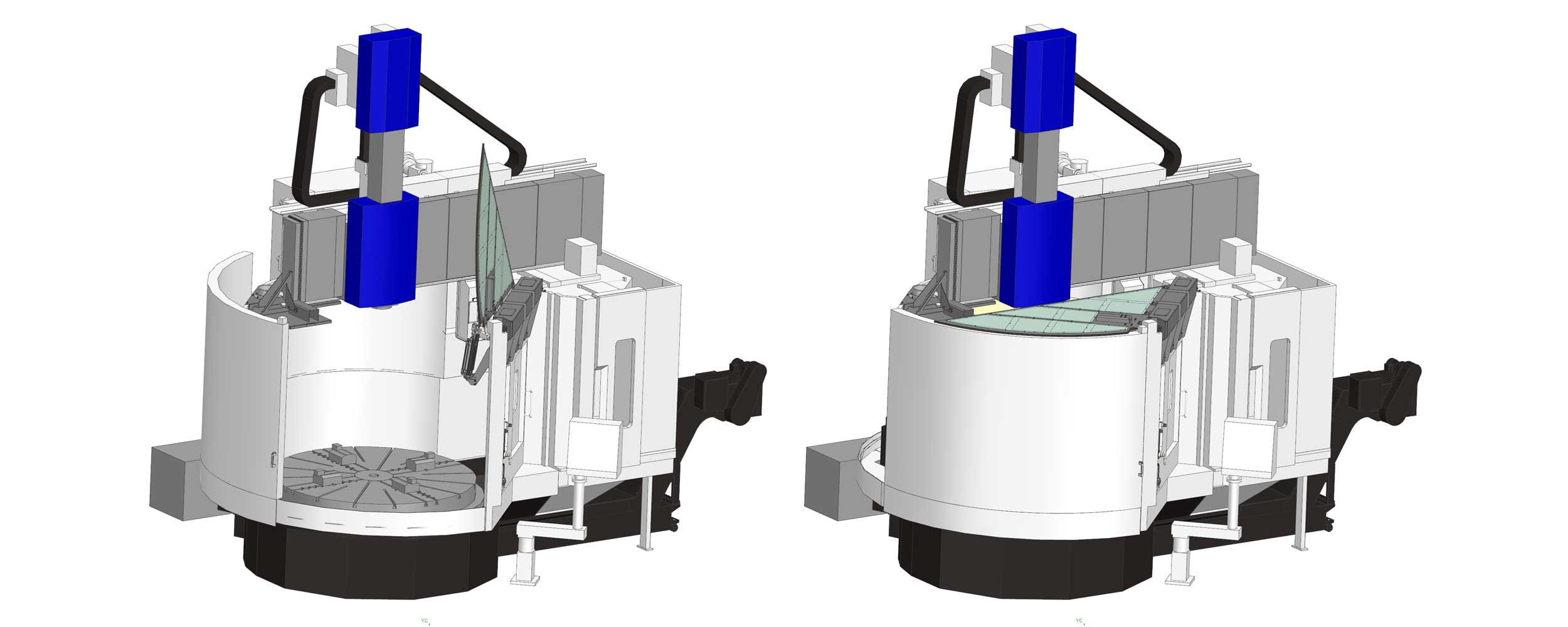

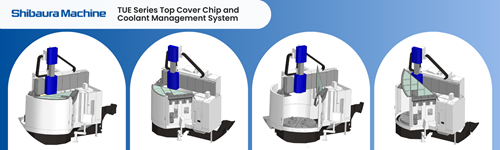

Having a well-designed chip and coolant management system is crucial. One of the most innovative solutions to this problem is the TUE Series Top Cover Chip and Coolant Management System. The new top cover for the TUE Series of vertical turning machines is an integrated enclosure that provides quick and easy access to the machine tool while preventing chips and coolant from exiting the machine tool workzone.

Keep Your Shop Running Smoothly

The design is specifically tailored to accommodate the axis of travel and swing clearance of TUE Series machine tools. The top cover is an optional feature available for both new and existing machines that adds another layer of coolant and chip management.

The system has several benefits, including:

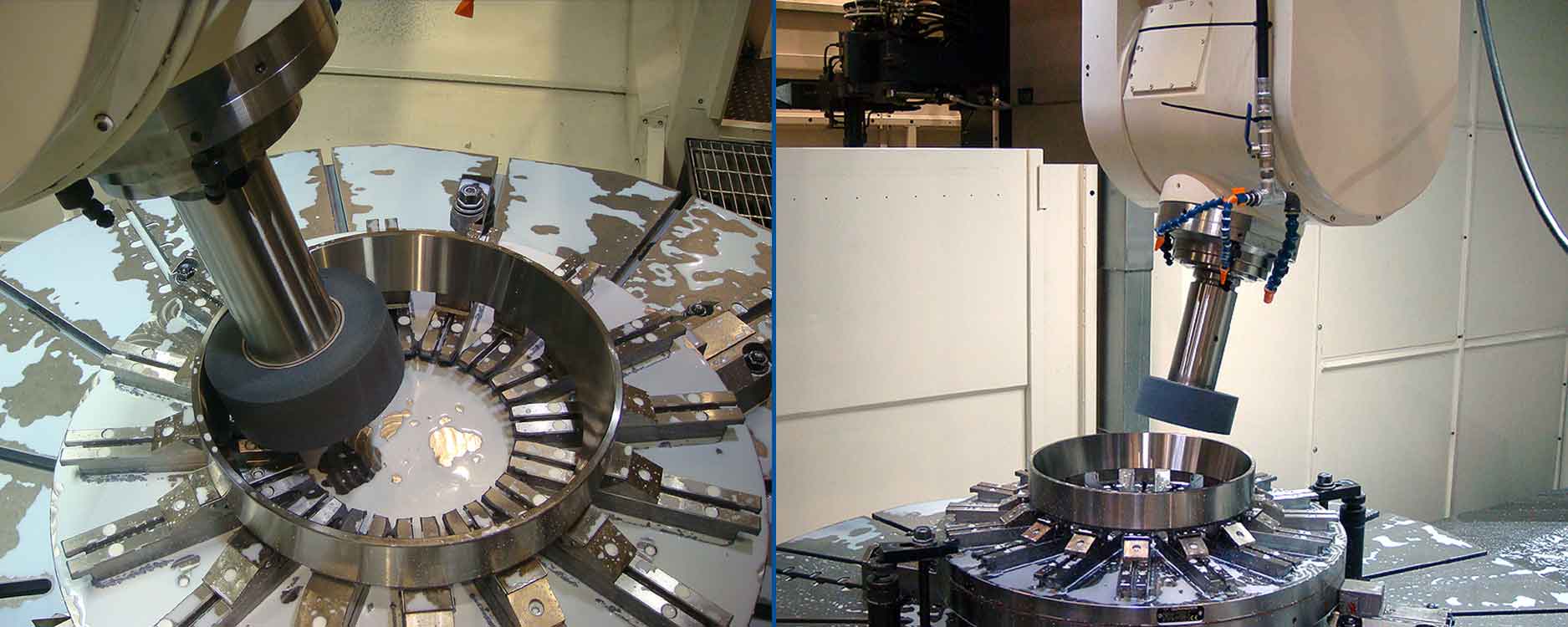

1. Improved Chip and Coolant Management

The top cover provides an additional layer that facilitates the management of coolant and chips in the machine tool workzone.

2. Increased Productivity

Poor chip management can create bottlenecks in the manufacturing process, ultimately hindering productivity. The Top Cover Chip and Coolant Management System helps to further minimize this issue.

3. Easy Access

The top cover is designed to provide quick and easy access to the machine tool, making maintenance and repair work more efficient.

4. Aesthetic Appeal

The TUE Series top cover has a sleek and modern design that adds to the aesthetic appeal of the machine tool.

An Innovative Solution to Coolant and Chip Management

Managing coolant and chips with a machine tool enclosure is a wise investment that will ultimately ensure the longevity of valuable machinery.

In addition to the TUE Series machine tools, Shibaura Machine offers a range of machine tool enclosure options for other machines such as horizontal boring machines, double column machines, and horizontal machining centers. Each enclosure is designed with rigidity, aesthetic appeal, and coolant and chip control in mind, providing a more productive work environment.

For those looking for a high-quality machine tool enclosure, contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

The Multi-tasking Capabilities of the Mill-Turn Machine Tool

ELK GROVE VILLAGE, IL, April 25, 2023 - Transitioning between machine tools is one of the biggest challenges for machinists. This can result in human errors during setup and the accumulation of processing errors. As a solution, multi-tasking tools are beco...

Read moreExploring the Versatility of Dynamic Part Probing for CNC Machine Tools

ELK GROVE VILLAGE, IL, April 19, 2023 - Dynamic part probing is a powerful tool that has transformed the way CNC machine tools operate in manufacturing. By using sensors and software to collect and analyze data in real-time during the machining process, dy...

Read morePrecise Machining on the MP-(U) for Challenging Materials with the Grinding Attachment

ELK GROVE VILLAGE, IL, April 05, 2023 - Multi-tasking machine tools have revolutionized the manufacturing industry, providing a versatile and efficient solution to various machining requirements. These machines are designed to perform several functions all...

Read moreMaximizing Horizontal Boring Machine Performance with TOSNUC and FANUC CNC Control Systems

ELK GROVE VILLAGE, IL, March 28, 2023 - Horizontal Boring Machines (HBM) have quickly become a critical component in the manufacturing process of various industries, and their precision and efficiency are vital for achieving high-quality results. One of th...

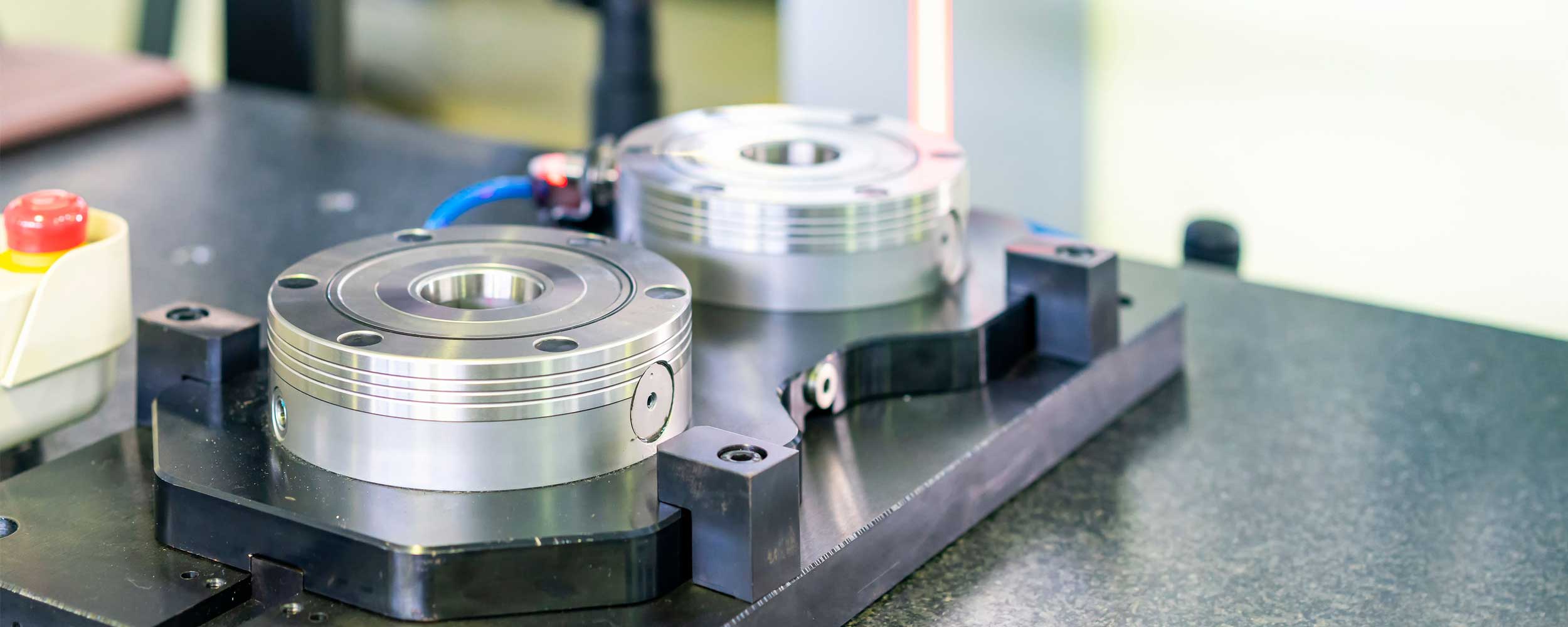

Read moreStart Improving Production With the Help of a Quick Change Workholding

ELK GROVE VILLAGE, IL, March 22, 2023 - In the world of manufacturing, time is money. Any downtime or delay in the production process can have a significant impact on a company's bottom line. This is where quick change workholding comes into play. Also kno...

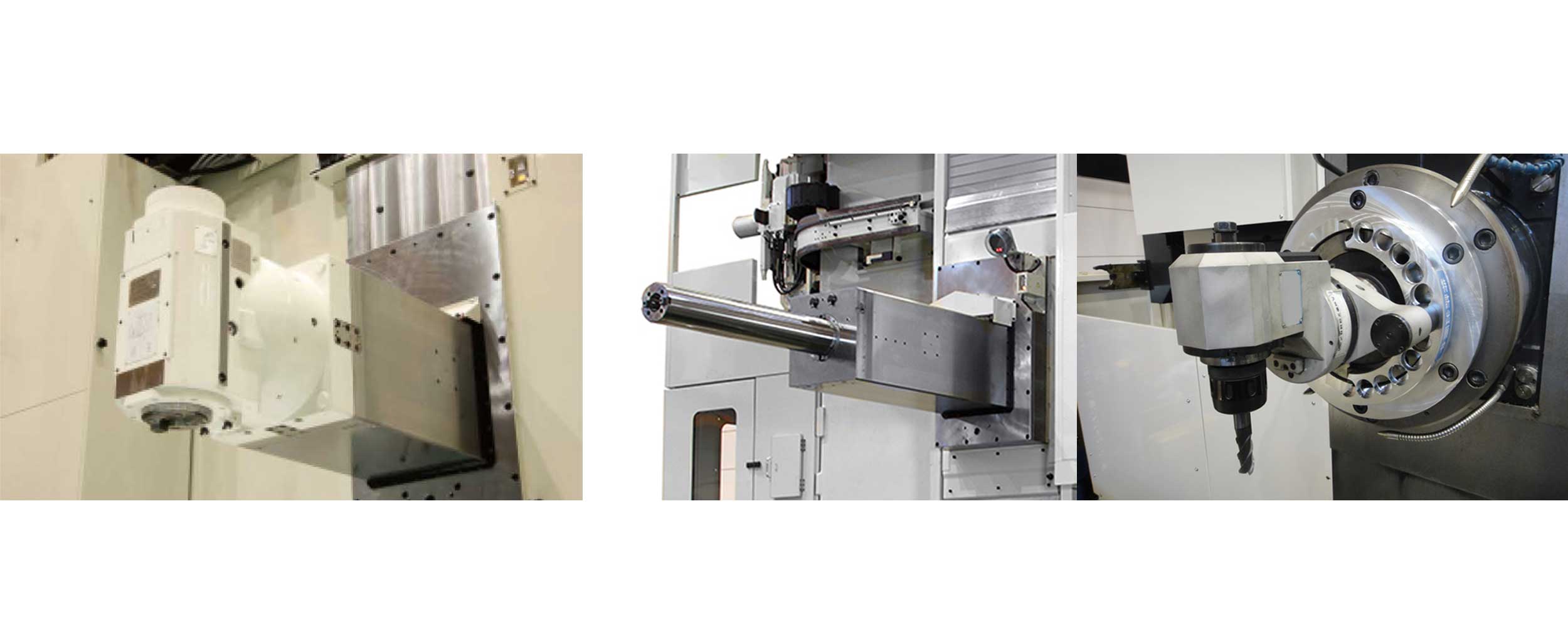

Read moreMaximizing Efficiency in Machining with the Right Angle Head Attachment on your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 14, 2023 - As a machine tool operator, you know that there are many challenges involved in performing precision cutting, drilling, and other operations. Machining complex workpieces with multiple surfaces often require numerous...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools