Keep Your Injection Molding Process Stable and Repeatable with Laminar Control

ELK GROVE VILLAGE, IL, October 29, 2021 - One of the best ways a molder can ensure quality parts consistently is by understanding and improving upon the injection speed process.

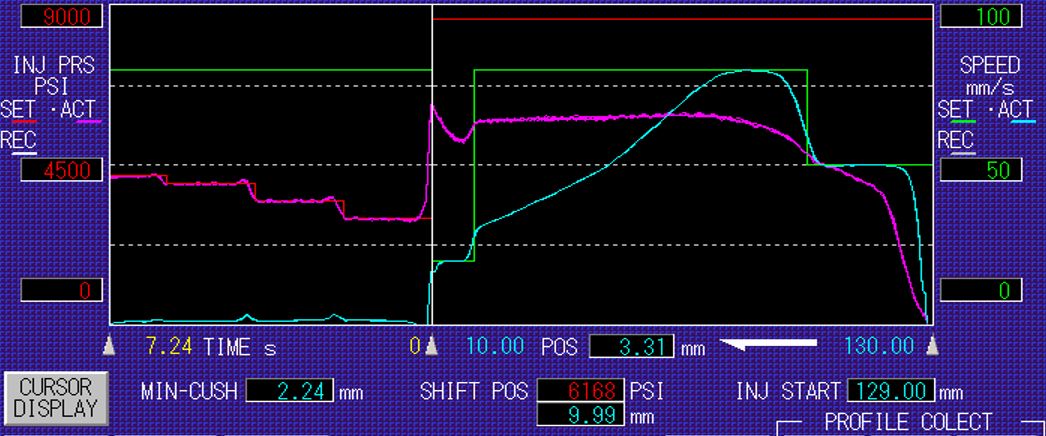

Shibaura Machine’s all-electric injection molding machines offer a Laminar Control function which helps alleviate issues when running a “pressure limited” process. What is a “pressure limited” process?. When the resin pressure rises during the filling process and reaches the filling pressure setting (PI), shifting from speed control to pressure control. The filling at constant pressure means uncontrolled filling speed creating inconsistencies in the repetition of the deceleration of the speed filling the cavities. The Laminar Control internally records the filling speed deceleration pattern and controls the filling speed so that it follows this pattern. This stabilizes the repeated filling speed when under pressure control.

Laminar Control Improves Shot-to-Shot Repeatability and Part Quality

At a glance, the Laminar Control function takes a snapshot of the injection speed profile of a good shot. The control records the injection speed profile in the internal memory and filling speed is controlled in accordance with that filling speed profile. When controlling the filling speed, the segment start position to the transfer to hold position is divided into 100 filling speed stages. This recreates the curved deceleration pattern shown below.

If you are looking to improve your injection molding process, contact our team to learn more about how the Laminar Control function on our all-electric injection molding machines will help - im-success@shibaura-machine.com.

Contact us today to see if Laminar Control can help your molding shop achieve its goals!

Related Articles View All Articles

Improve Injection Molding Part Quality with the DST-Press Function on Shibaura Machine’s ECSXIII Series

ELK GROVE VILLAGE, IL, October 27, 2021 - While injection molding is a versatile way to produce parts and products, it can be complex and challenges often arise. One of the most common concerns manufacturers have is creating a consistent and repeatable pro...

Read moreResin Viscosity Changes Affecting Your Injection Molding Process? DST-Fill Can Help!

ELK GROVE VILLAGE, IL, October 20, 2021 - Many variables can affect the injection molding process. Of these variables, resin viscosity is perhaps the most critical. Oftentimes the viscosity of materials is neither consistent nor predictable resulting in an...

Read moreStabilize Your Injection Molding Process with Filling Impulse Transfer (F.I.T.)

ELK GROVE VILLAGE, IL, October 4, 2021 - While most modern all-electric injection machines have high levels of repeatability, molding defects can still be an issue due to material property inconsistencies. Perhaps the material lot has changed or the percen...

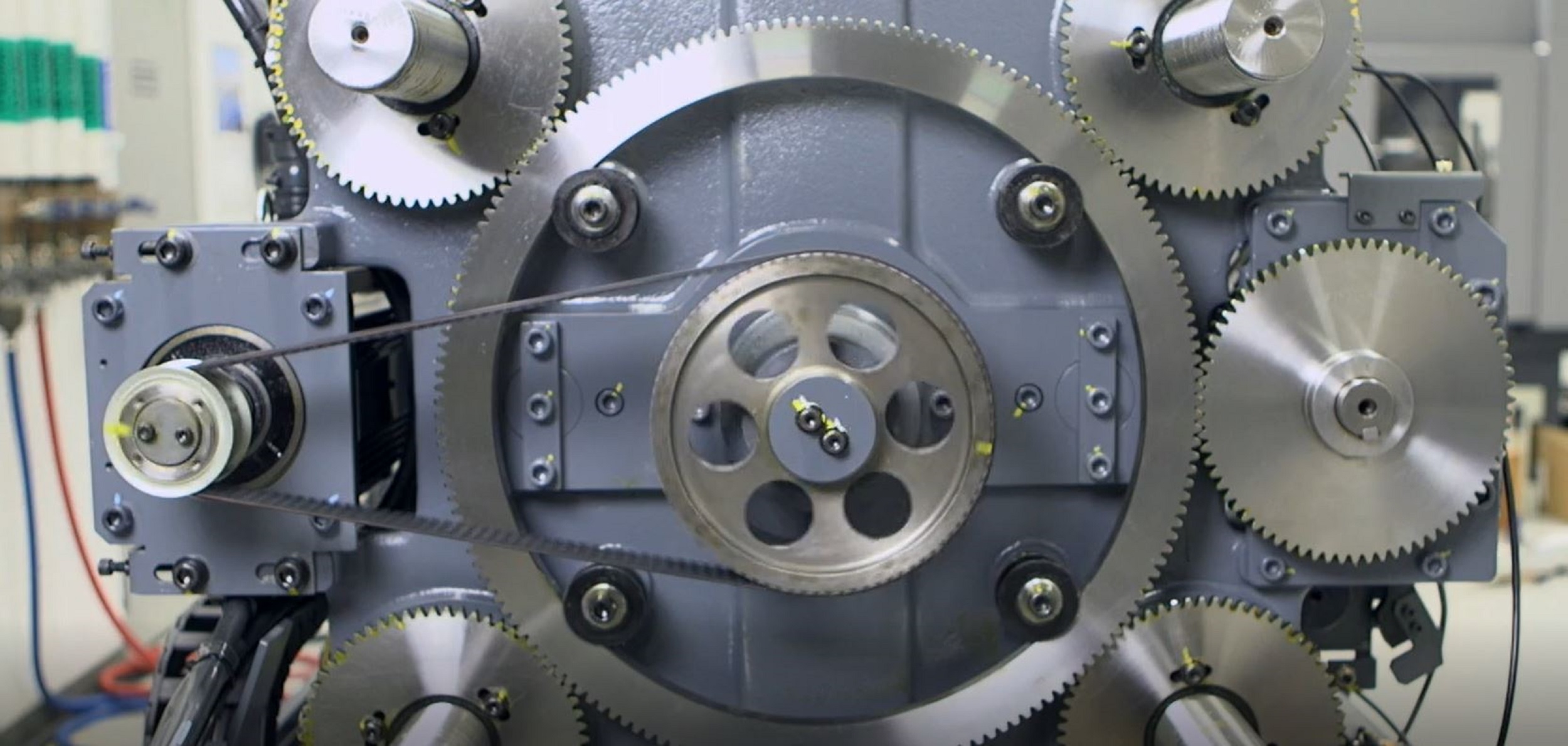

Read moreBelt Drive or Direct Drive? Shibaura Machine is Breaking Down the Differences

ELK GROVE VILLAGE, IL, September 22, 2021 - Linear motion control systems, such as direct drive and belt drive, are key in today’s motion-driven automation environment. And while both options look similar, they are both fundamentally different. You will wa...

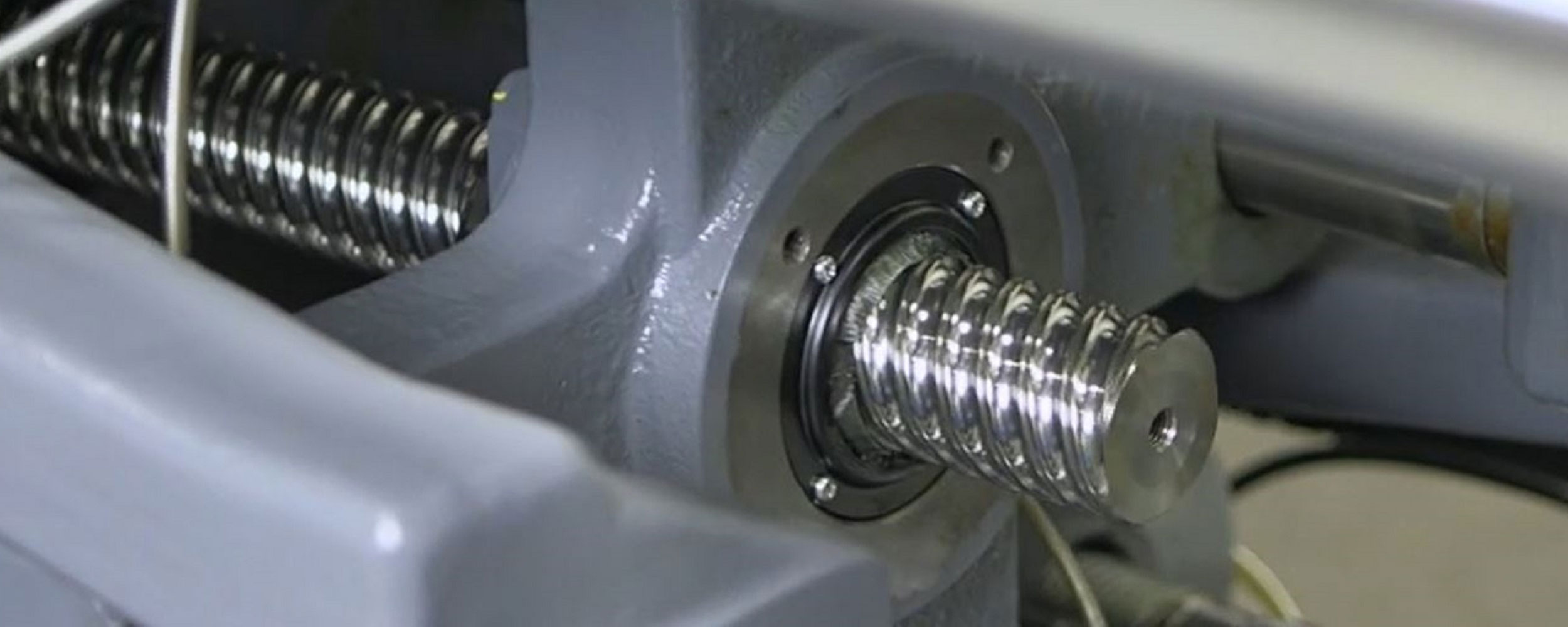

Read moreThe Benefits of Shibaura Machine’s Proprietary Injection Molding Servo Motor and Ball Screw Design

ELK GROVE VILLAGE, IL, September 17, 2021 - As the technology for injection molding machines continues to evolve, all-electric has become an increasingly popular option. When it comes to comparing and choosing the right all-electric machine for your factor...

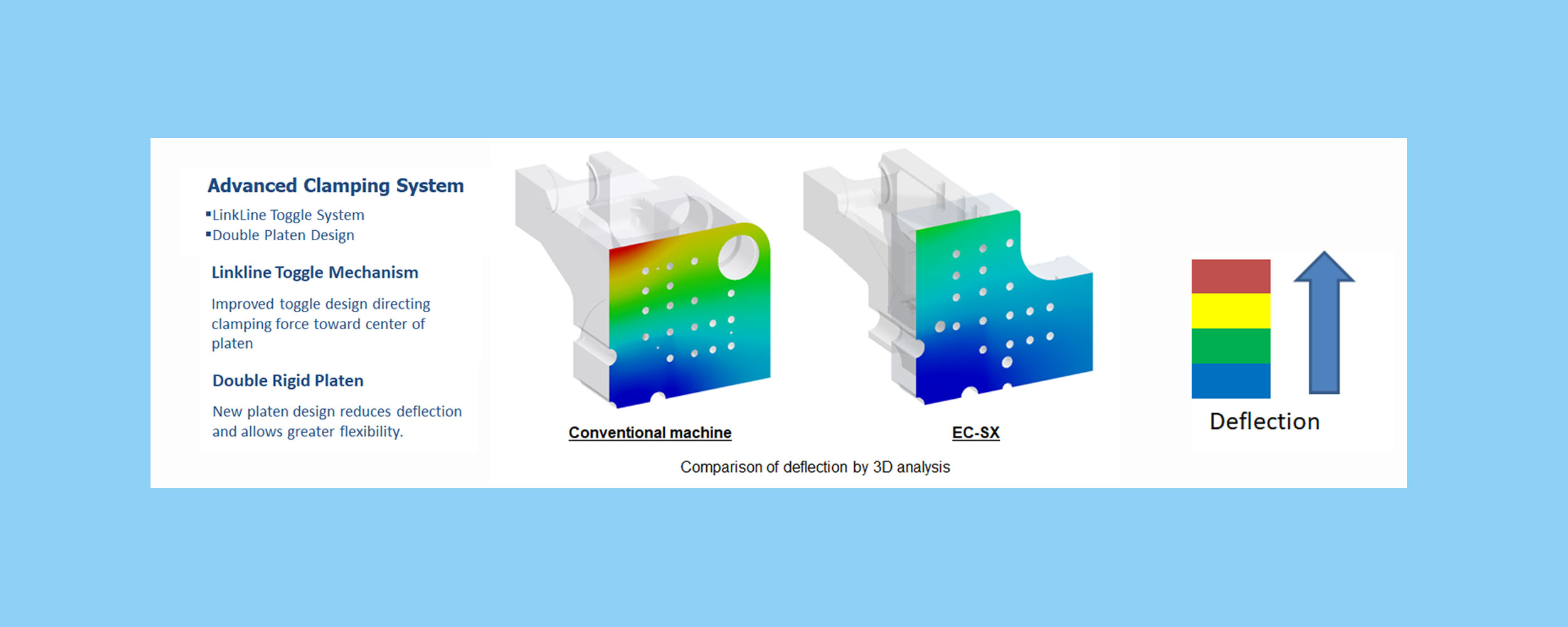

Read moreMold Deflection Causing Problems With Your Injection Molding Process? Read This.

ELK GROVE VILLAGE, IL, September 9, 2021 - When it comes to manufacturing plastic parts to tight tolerances, minimizing mold deflection is essential. Mold deflection is generally caused by clamping and cavity pressures which then cause the mold to deflect ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools