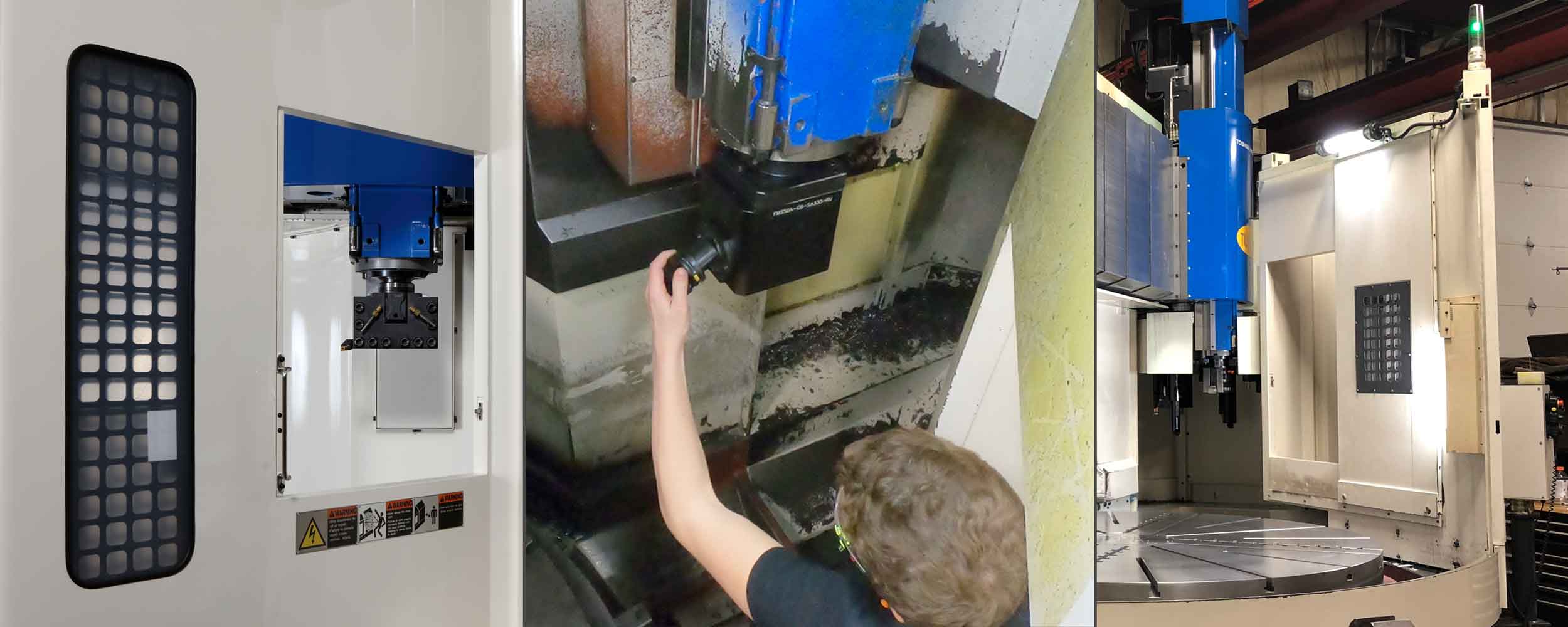

Reduce Tool Changeover Times with Convenient Access Door

ELK GROVE VILLAGE, IL, January 5, 2022 -

A machine operator knows that a tool holder provides a safe critical interface between the cutting tool and the spindle of the machine. With the cutting tool mounted in the holder, it provides the stability to ensure a precise cut each time.

Changeout and rotation of cutting tools can be cumbersome if the entire tool holder/block assembly needs to be removed. It means shutting down the machine tool and extra downtime in making a safe change. Money is being wasted by halting production and putting operators on this task when they could be operating the machine, running parts.

A Simple Solution to Tool Changeover

The Shibaura Machine VTL model TUE (S) access door allows machine operators to safely access the tool holder for changing out active cutting tools without needing to remove the tool holder/block assembly. Rather than disrupting production, operators can now change out cutting tools safely and without having to completely halt production by using the access door feature. The convenience of the access door provides a faster way to service active tooling without the need for a tool change, improving cycle times.

Changing out tools in a timely fashion without interrupting a job can give the competitive advantage your shop needs. Dull tools tend to produce extra scrap, preventable failures, and additional labor for change out. Using the access door allows for safe, easy, and timely tool changes.

Improve Machining Operations

The CNC vertical boring and turning mills in the TUE (S) series provide the rigidity and accuracy required for high performance machining. The access door feature is one example of how Shibaura Machine empowers customers to improve production and reduce costs with increased machine flexibility. Specifically, for customers with the Sandvik CAPTO tool holders, operational efficiency and accuracy will be improved.

Contact the machine tool team to learn more about all the features on the TUE (S) series.

Learn more about our TUE (S) series.

Related Articles View All Machine Tools Articles

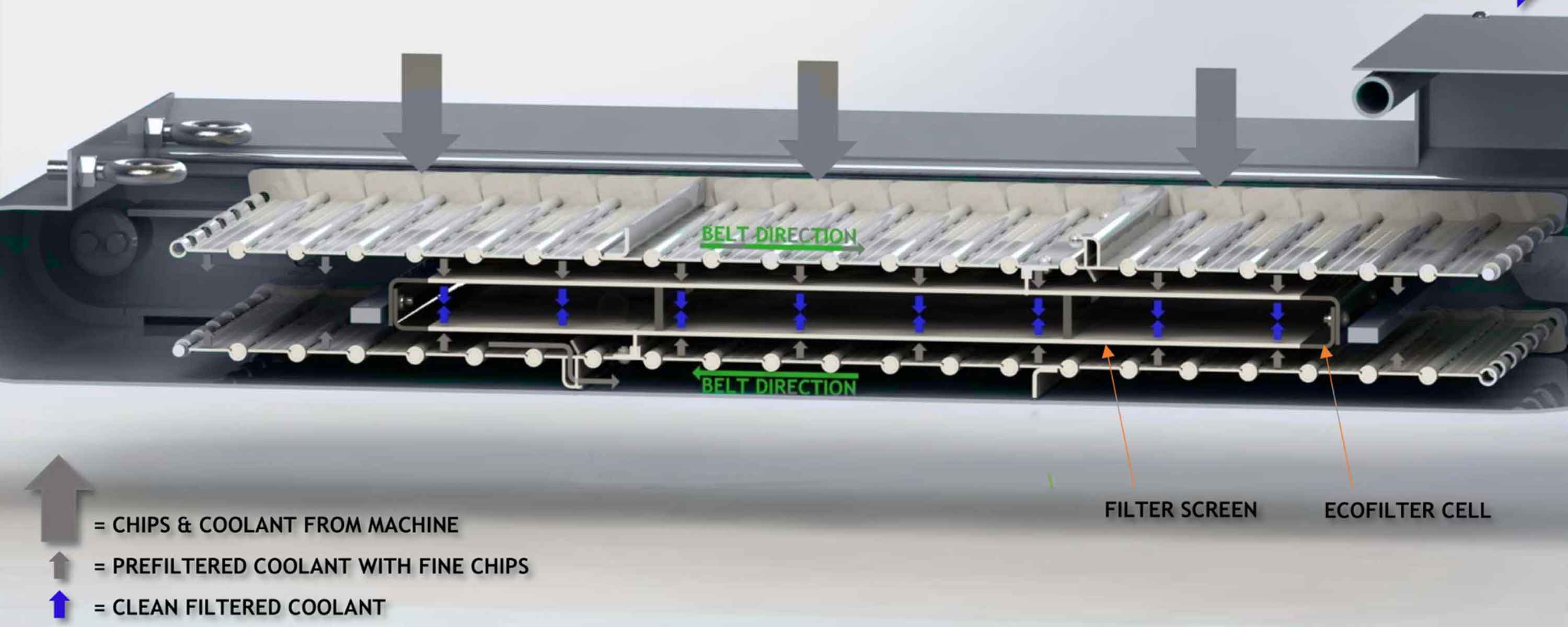

Looking to improve chip filtration on your machine tool? Consider this.

ELK GROVE VILLAGE, IL, December 8, 2021 - Maximizing machine tool output is the goal for today’s industrial manufacturing applications. Being able to machine as many quality parts in the shortest amount of time allows for higher profitability and return on...

Read moreSpotlight: Machine Tool Customer Support Team

ELK GROVE VILLAGE, IL, December 2, 2021 - When customers purchase from Shibaura Machine, they know they are getting a high-performance machine tool. Ensuring you maintain the high-performance of your investment is just as important, if not more, then the i...

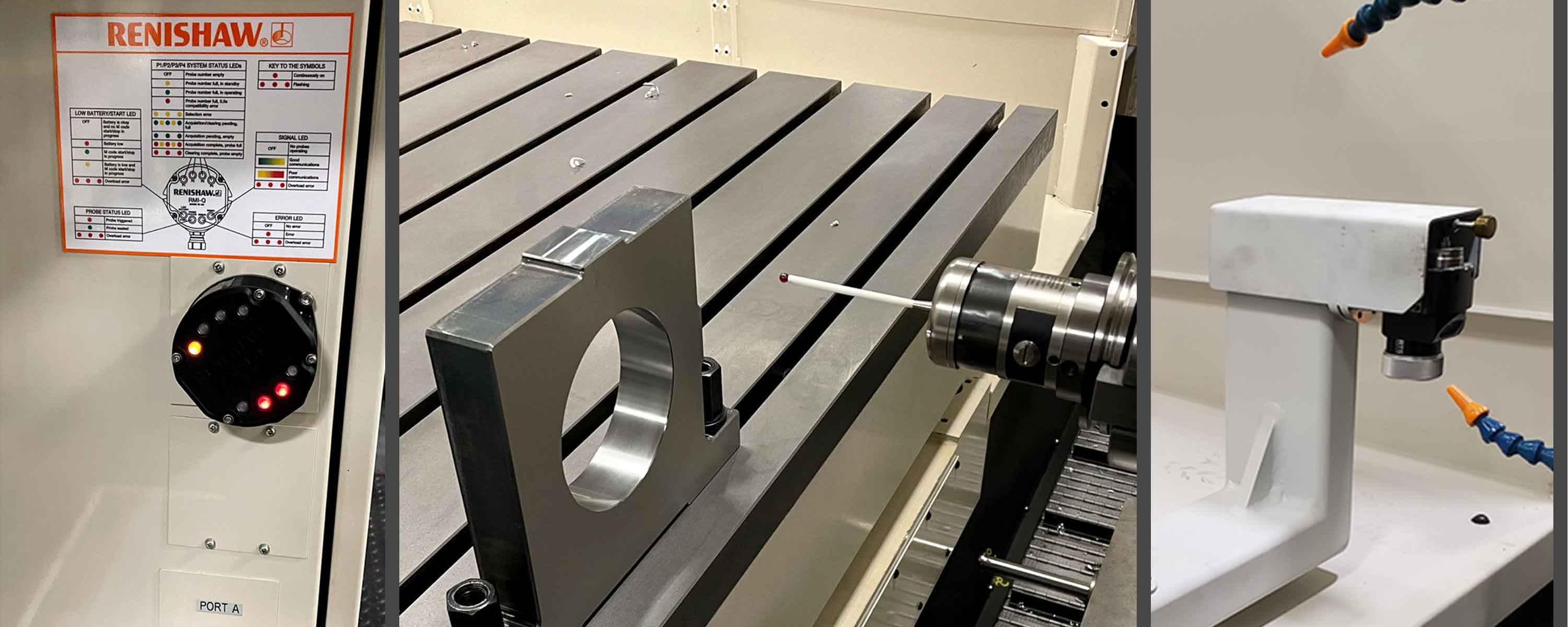

Read moreAutomated Machine Tool Health Checks Improve Productivity

ELK GROVE VILLAGE, IL, November 22, 2021 - Time is money. Being able to quickly identify problems when it comes to machine set-up, collisions, and wear can help shops save on both performance and profitability. Probing also offers both an easy and reliable...

Read moreHighlighting the Renishaw OSP60 Probe for Your Machine Tool

ELK GROVE VILLAGE, IL, November 15, 2021 - One constant in manufacturing is the need to focus on operating margins in order to remain competitive. What are the best ways to improve productivity and precision while boosting profits?Probing has been a long e...

Read moreUnderstand the Benefits of a Tool Setting Probe for Your Shibaura Machine Tool

ELK GROVE VILLAGE, IL, November 9, 2021 - Going into 2022 shops are focused on ways to improve workpiece quality, while saving time and money. One of the most efficient ways to optimize your processes from the ground up is to consider adding a tool setter....

Read moreAdding a Workpiece Inspection Probing System to Your Machine Tool Is Worth Considering

ELK GROVE VILLAGE, IL, November 2, 2021 - As machine tool automation advances, more manufacturers are looking towards the addition of a inspection probing system to help them make a bigger impact on their performance and profitability. That is why Shibaura...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools