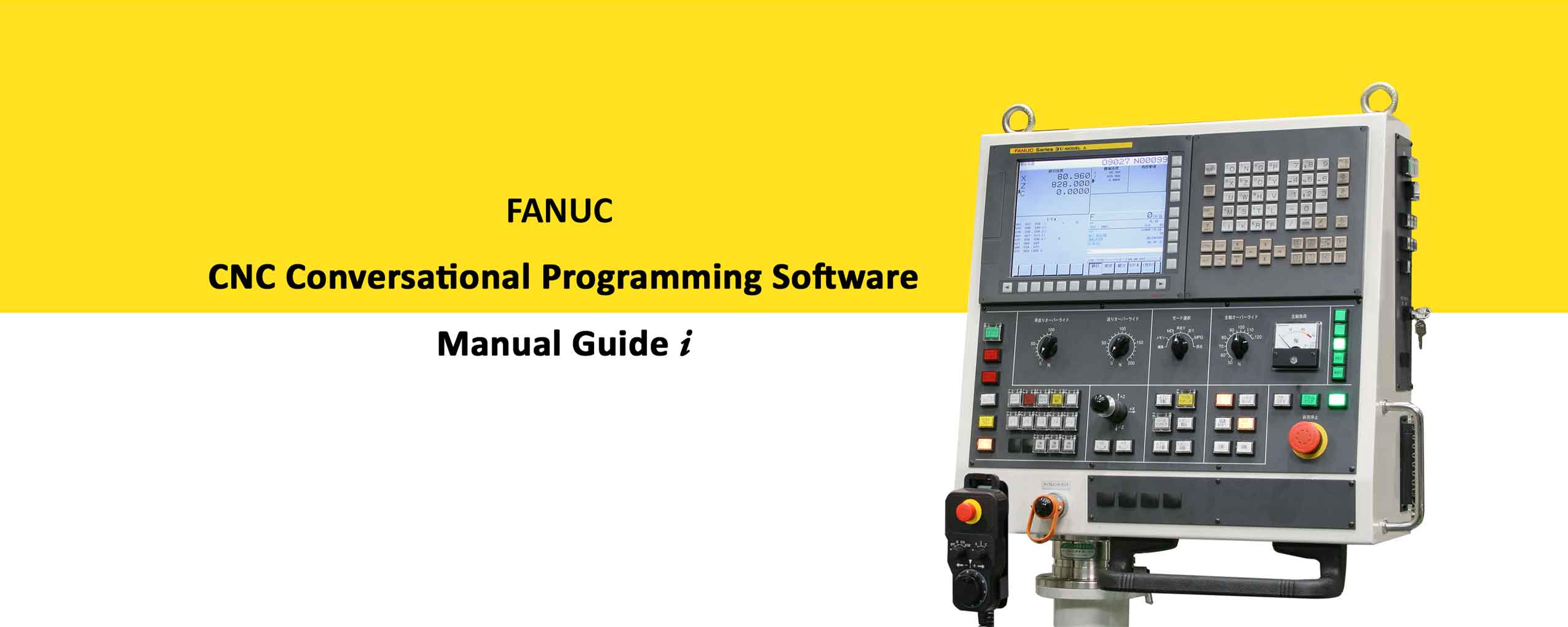

Shop Floor Programming with Manual Guide i

ELK GROVE VILLAGE, IL, January 12, 2022 -

Improving production cycle times is a top shop goal to achieve this year. Conversational and/or shop floor programming software has quickly become a popular option to help meet these goals. Without knowing G-code, machinists can efficiently create part programs and speed up production processing utilizing this form of programming.

Shibaura Machine has integrated Fanuc Manual Guide i to allow machinists to easily generate programs on their CNC machine control. In a matter of minutes, machinists are guided through the machine process with a series of built in data prompts allowing them to quickly generate an accurate program.

Easier Part Design for All Skill Levels

Manual Guide i allows for a fast solution that all skill levels can master for drawing part designs directly on the machine’s control unit. Those without programming knowledge will appreciate the graphical interface with user-friendly icons to allow for part program creation in a few interactive steps on one CNC screen and the ability to potentially transition into G-code.

In a short matter of time any machinist can be taught to use Manual Guide i.

Improved Part Production

Even for some complex machining processes, users can produce highly efficient results with the self-explanatory menus and graphic simulations guide. Based on the ISO code format, it displays all relevant information.

A quick overview of the process to create a program:

- Create and name a new program

- Set initial conditions and input material blank size

- Insert cutting conditions and define shape geometry

- Check your programs easily with program check

From development to drawing to production, this innovative programming creates an improvement on part production.

Learn More

Contact our Machine Tools sales department to learn more about the ways in which utilizing Manual Guide i can help you efficiently create simple part programs and speed up your production processing time.

Related Articles View All Machine Tools Articles

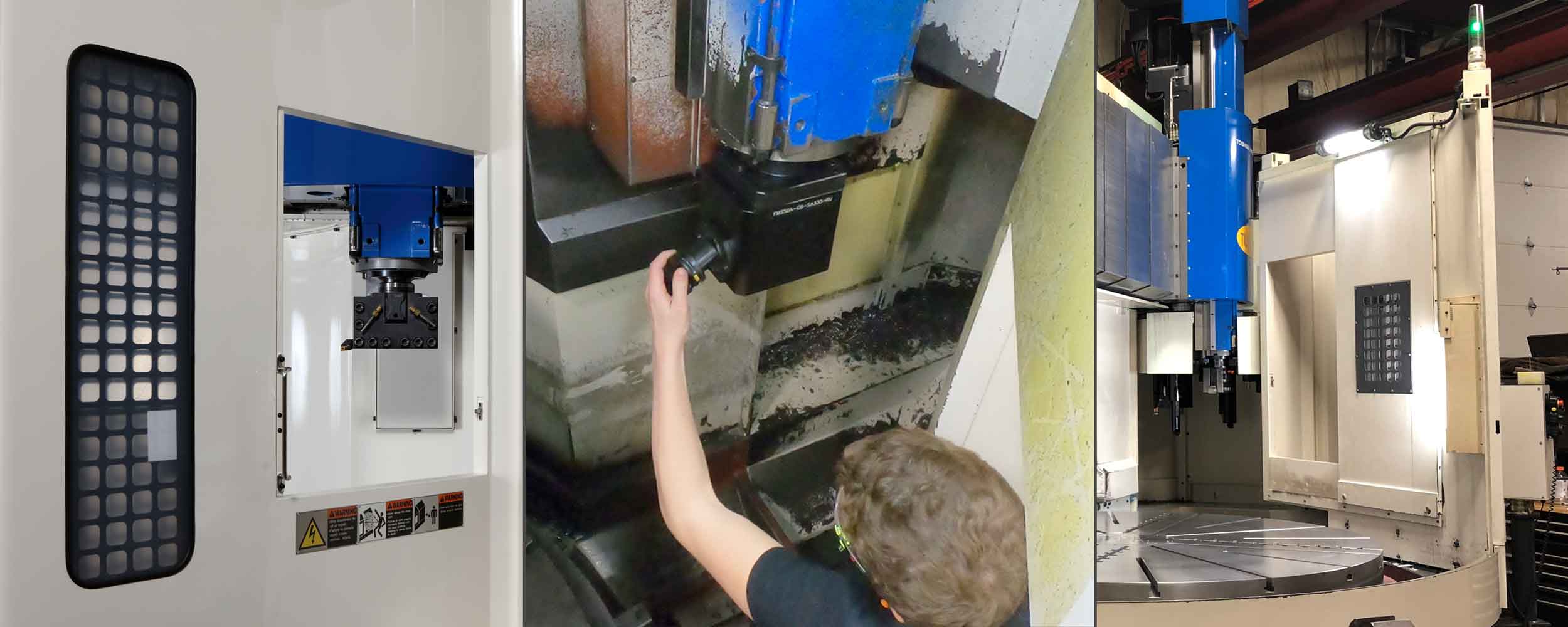

Reduce Tool Changeover Times with Convenient Access Door

ELK GROVE VILLAGE, IL, January 5, 2022 - A machine operator knows that a tool holder provides a safe critical interface between the cutting tool and the spindle of the machine. With the cutting tool mounted in the holder, it provides the stability to ensur...

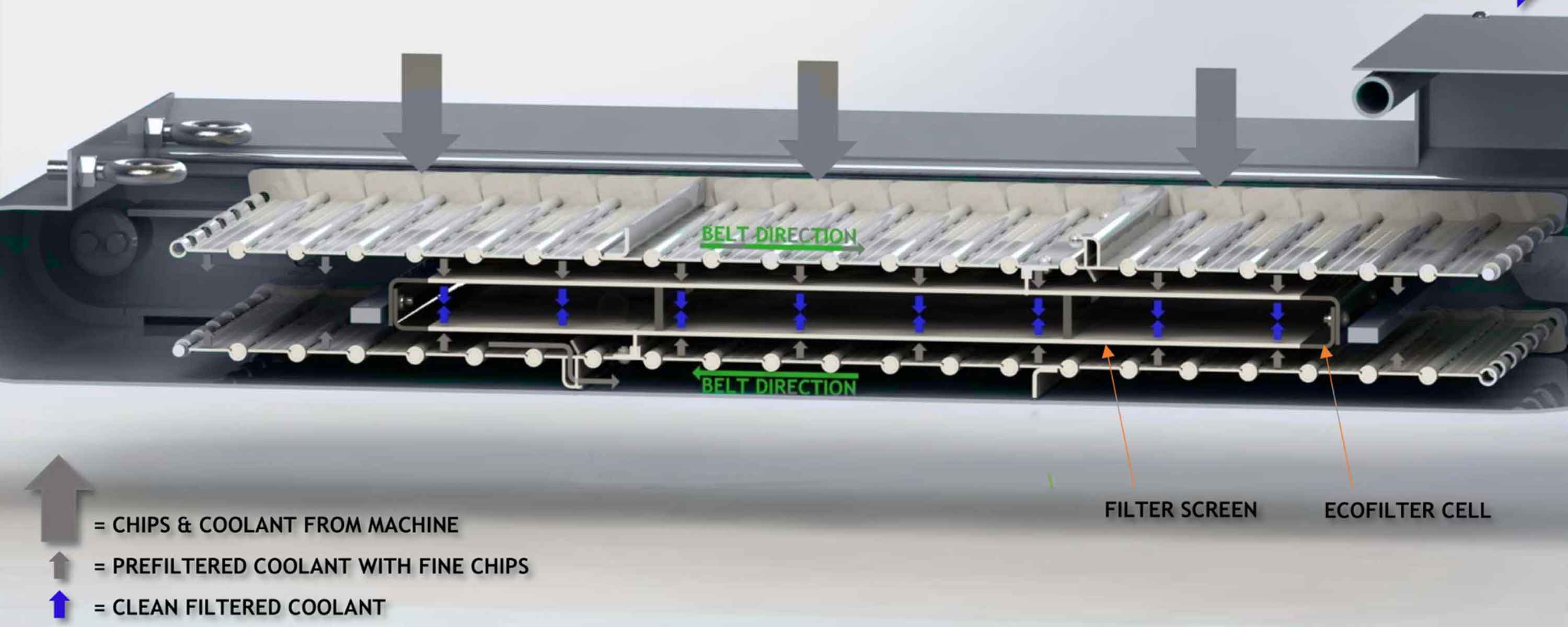

Read moreLooking to improve chip filtration on your machine tool? Consider this.

ELK GROVE VILLAGE, IL, December 8, 2021 - Maximizing machine tool output is the goal for today’s industrial manufacturing applications. Being able to machine as many quality parts in the shortest amount of time allows for higher profitability and return on...

Read moreSpotlight: Machine Tool Customer Support Team

ELK GROVE VILLAGE, IL, December 2, 2021 - When customers purchase from Shibaura Machine, they know they are getting a high-performance machine tool. Ensuring you maintain the high-performance of your investment is just as important, if not more, then the i...

Read moreAutomated Machine Tool Health Checks Improve Productivity

ELK GROVE VILLAGE, IL, November 22, 2021 - Time is money. Being able to quickly identify problems when it comes to machine set-up, collisions, and wear can help shops save on both performance and profitability. Probing also offers both an easy and reliable...

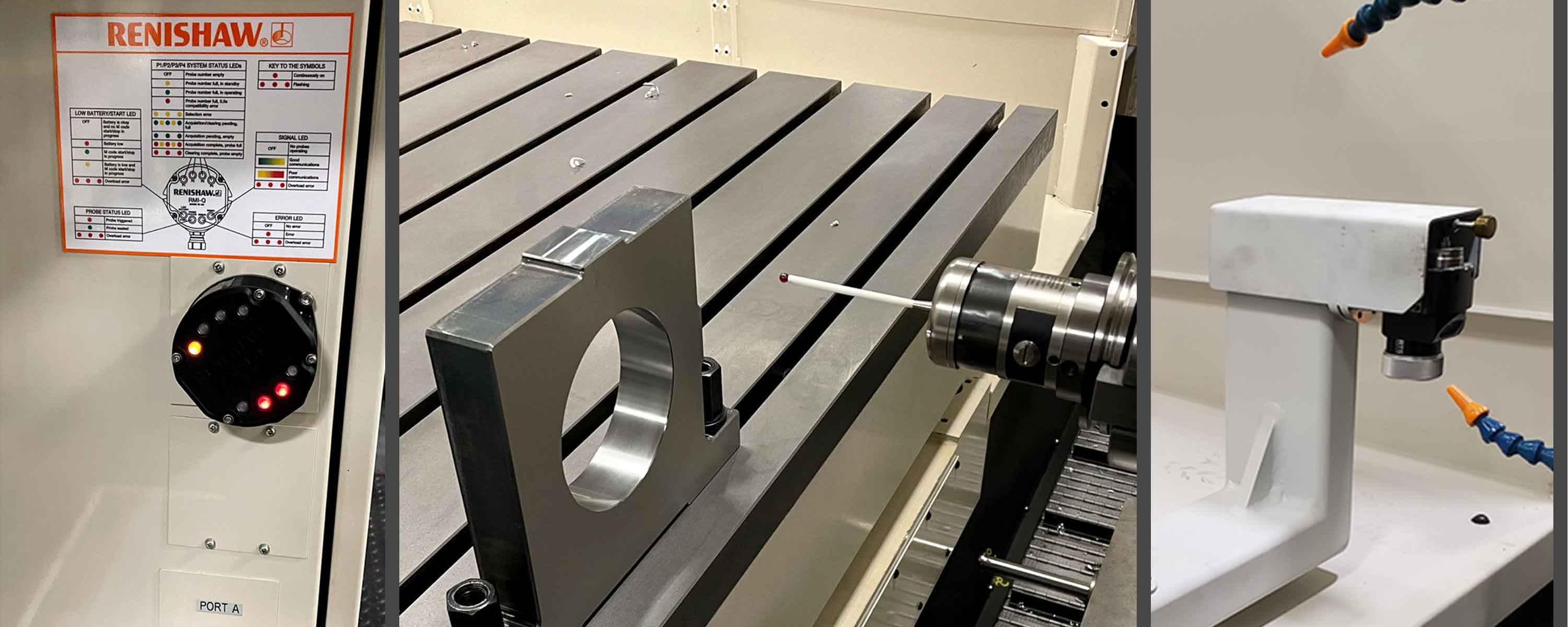

Read moreHighlighting the Renishaw OSP60 Probe for Your Machine Tool

ELK GROVE VILLAGE, IL, November 15, 2021 - One constant in manufacturing is the need to focus on operating margins in order to remain competitive. What are the best ways to improve productivity and precision while boosting profits?Probing has been a long e...

Read moreUnderstand the Benefits of a Tool Setting Probe for Your Shibaura Machine Tool

ELK GROVE VILLAGE, IL, November 9, 2021 - Going into 2022 shops are focused on ways to improve workpiece quality, while saving time and money. One of the most efficient ways to optimize your processes from the ground up is to consider adding a tool setter....

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools