Minimizing Injection Molding Complexity without Compromising Capability

ELK GROVE VILLAGE, IL, February 10, 2021 – The convenience of your injection molding machine controller correlates directly with your factory production efficiency. A controller that is not only powerful but offers intuitive operation, simple navigation, and a smart user interface offers a competitive edge and the ability to improve overall equipment effectiveness.

Shibaura Machine remains committed to developing products that offer our customers ways to do things simpler, safer, and more efficient. Through the evolution of many generations of controllers, our current V70 machine controller offers one of the most user-friendly experiences in the industry.

Convenience and Power in One

When upgrading to the V70 controller we wanted to make sure the user experience offered the ability to efficiently accomplish tasks, reduce error, and improve overall operation.

The V70 controller is equipped with a variety of features and functions including:

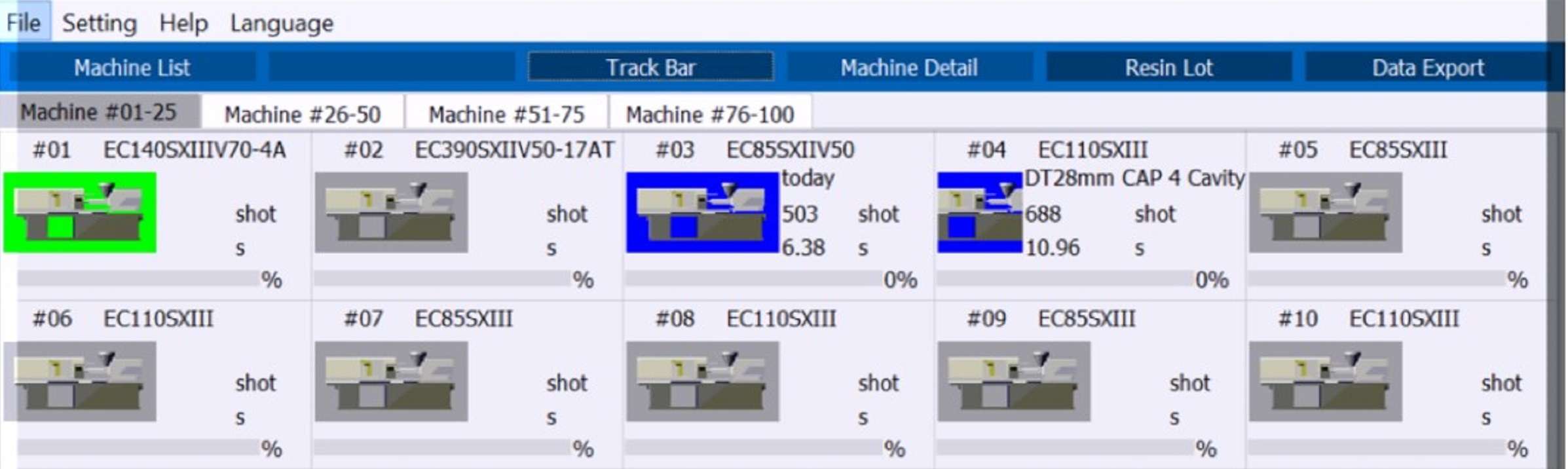

- Smart controls: Intuitive user experience with a 19’’ touch screen that offers color-coded speeds, pressures, timers, positions, and temperatures for easy recognition, controller screens laid out in the same orientation as the molding machine, and drag and drop icons to ensure consistent sequencing.

- Easy visibility: Users can access more information, quicker with features like the split-screen offering unparalleled visibility of the molding process such as viewing the injection screen and injection graphic profile screen simultaneously, the ability to get to any screen in two touches or less, and a searchable machine manual in the onboard PDF library.

- Customized experience: Customer-specific and customized information are easily accessible. Customers can design the screen layout to best fit their processing needs, the clamp sequence page offering a visual representation of clamp cycles to reduce operator error and 6 programmable machine outputs can be used to send signals to ancillary equipment such as color feeders, conveyors, etc.

- Upgraded troubleshooting/maintenance tools: Quickly understand how to improve output with the cycle analysis screen to see where cycle time can be reduced, use the mold support function to help resolve quality defects, get automatic preventative maintenance reminders, and more.

Shibaura Machine understands that being able to streamline the workflow, from setup through production, can greatly impact a factory’s OEE. The V70 controller allows customers to minimize complexity without compromising the machine’s abilities. The controller gives users the ability to develop even the most sophisticated applications. Our SXIII series all-electric machines comes standard with the V70 controller.

Click below to learn more about the industry's most user-friendly controller platform!

Related Articles View All Articles

All-Electric Injection Molding Machines Offer More Than Energy Savings

ELK GROVE VILLAGE, IL, February 3, 2021 – Did you know energy spending in most injection molding plants is one of the highest costs month after month? At the end of the day, it is often costing more to run old machines then it would to invest in new, energ...

Read moreImprove Quality Control and Productivity with the iPAQET Remote Data Management System

ELK GROVE VILLAGE, IL, January 27, 2021 – Not all monitoring and data management systems are created equal. Many systems are prone to errors, have less than easy to use interfaces, or require someone to be in front of the machine- oftentimes collecting dat...

Read moreHow to Minimize Injection Molding Machine Downtime

ELK GROVE VILLAGE, IL, January 19, 2021 – Whether planned or unplanned, machine downtime is very costly. Aside from directly impacting production and labor, machine downtime extends to other areas of operation and can affect the organization as a whole. An...

Read moreReducing Reject Rates for Injection Molding is Within Reach

ELK GROVE VILLAGE, IL, January 13, 2021 – If parts are considered defective they are likely getting rejected by customers. That means the cost lands on you, but with a premium because you have equipment and labor costs tied into it. Luckily, the right inje...

Read moreReducing Injection Molding Cycle Times Using All-Electric Technology

ELK GROVE VILLAGE, IL, January 5, 2021 – When it comes to improving manufacturing processes, optimizing the parameters of your injection molding machine is critical. Specifically, working to reduce cycle times in injection molding can allow you to produce ...

Read moreEvolving with Our Injection Molding Customers through Superior Support

ELK GROVE VILLAGE, IL, December 29, 2020 – Making an investment in an injection molding machine is as much about the people behind it as the machine itself.Having a true partner that works to find ways to minimize downtime, improve efficiency, and keep you...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools