Why Reliable Temperature Control is Critical to Your Die Casting Success

ELK GROVE VILLAGE, IL, July 22, 2021 -

What does temperature have to do with it?

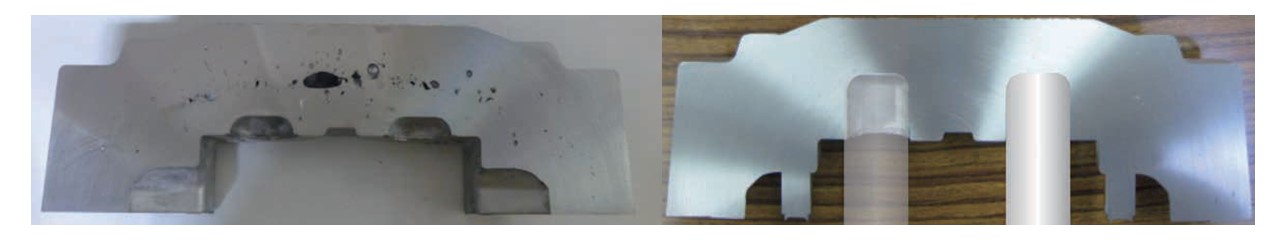

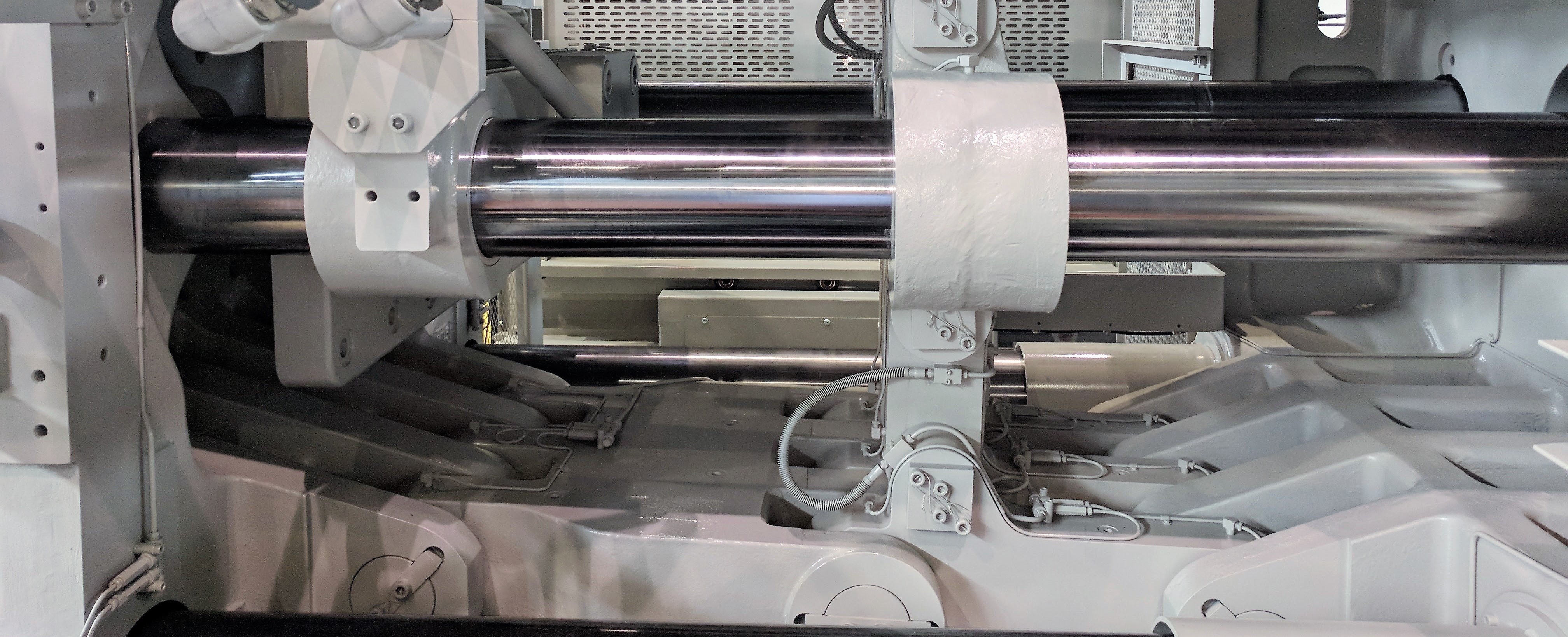

If you’re involved in die casting production then you know it's everything. Even a slight fluctuation in temperature can mean major damage and defects. Ensuring a well-controlled temperature will not only make for uniform high quality cast parts, but improve cycle times and in many cases can extend die service life.

Rewind back a few decades and some might remember the manual effort required to maintain the correct temperature in die casting. Craftsmen would need to be educated and skilled on how to judge the alloy temperature by color and flow. The sizzle of the die spray on the die surface told him exactly the temperature of the steel and they would be able to react and compensate for any changes to these temperatures.

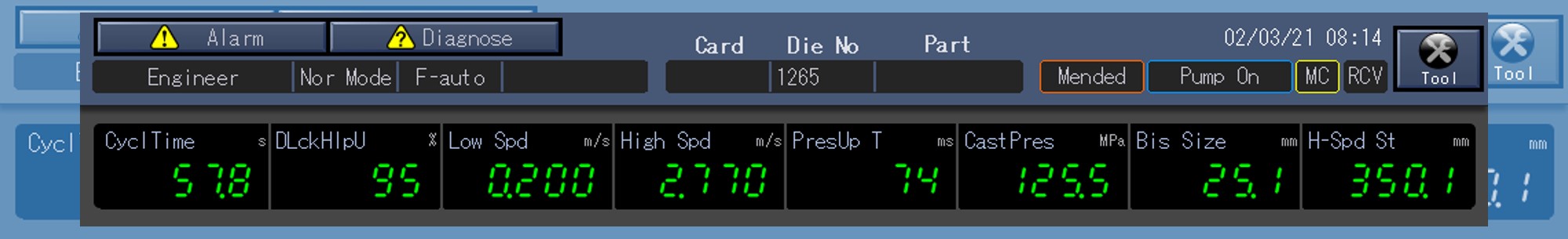

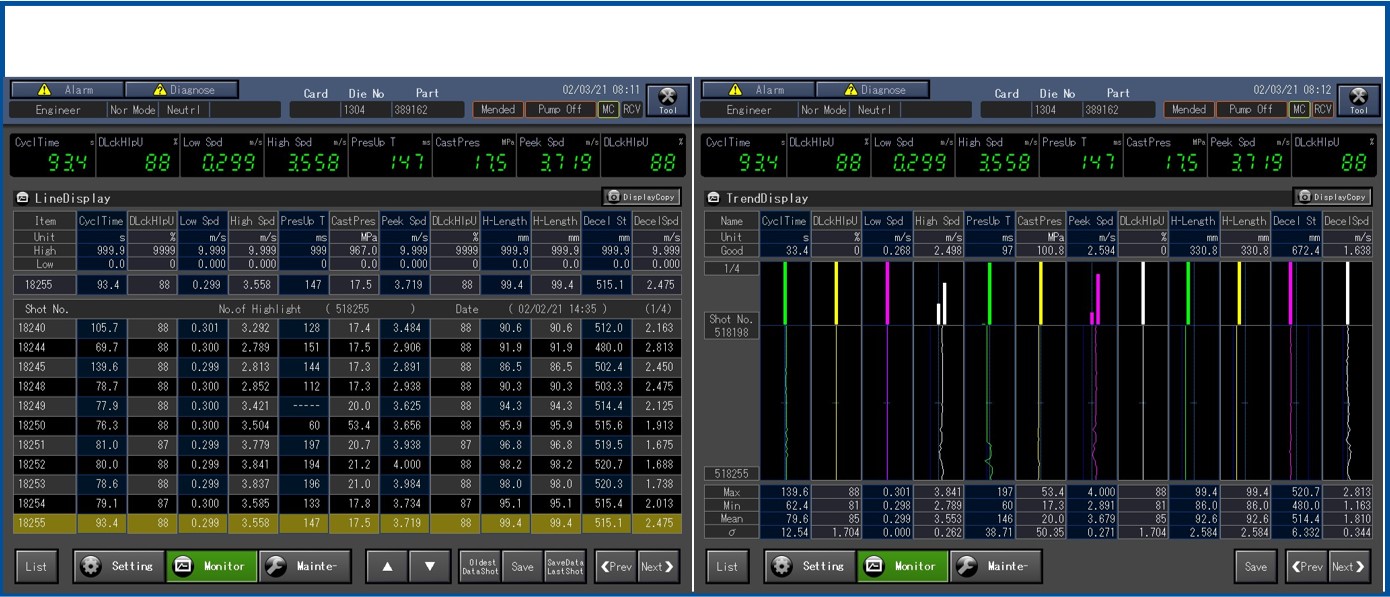

Those days are past us and we can now utilize die temperature control systems to heat the die and maintain it at required temperatures. The engineers at Shibaura Machine developed the Thermal Card function within the TOSCAST-888 to offer an easy-to-use, robust, high-performance way to monitor temperatures in the system.

Proven and Reliable Die Temperature Control

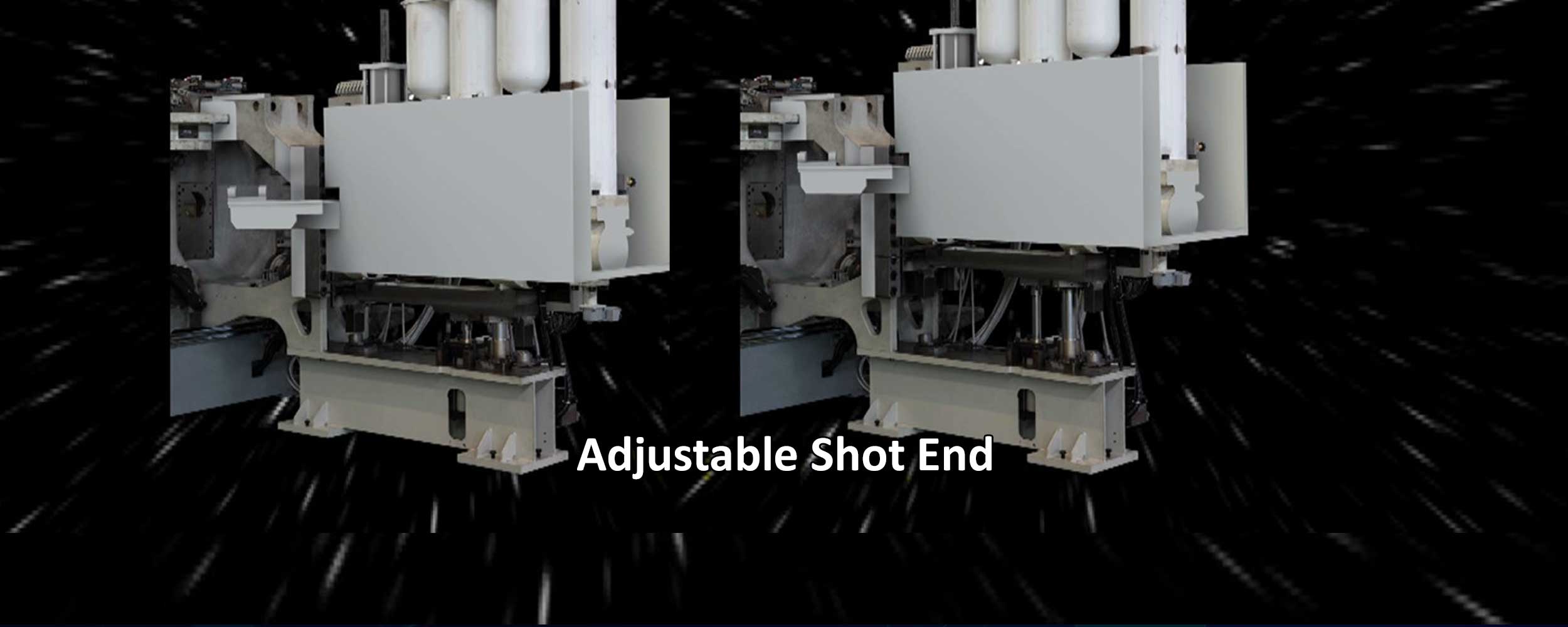

Die casting of today heavily relies on reliability of the technology in front of the operators. Shibaura Machine’s state-of-the-art die casting system offers accurate readings of a wide variety of temperatures- easily put, if it has a temperature, the system can read it.

The temperature monitoring functions of the TOSCAST-888 system allow the operator to qualify the readings from many types of thermal sensors, including:

- The temperature of the die itself

- The temperature of the die casting machine or casting chamber

- The temperature of the alloy used for casting

Understanding these temperatures allows the operator to make quality and production decisions to correct or stop the process. Keeping these temperatures in their optimal ranges will allow for the production of higher quality die cast parts.

Temperature is not something you want to have your operators guessing on. Take advantage of the thermal card function on the TOSCAST-888 system to start optimizing cycle times and improving part quality. If you don’t currently operate with Shibaura Machine’s TOSCAST-888, contact our team to learn more about how this system can help.

Contact us today to learn how our TOSCAST-888 can monitor the temperature of your process for you!

Related Articles View All Articles

Control Porosity in Die Casting Easier with Shibaura Machine

ELK GROVE VILLAGE, IL, November 18, 2021 - The tiny pockets of air and small voids found in parts that we call porosity can quickly turn into a manufacturer's worst nightmare. Porosity in parts can not only harm a component's structural integrity, but al...

Read moreNever Be Left Wondering in Die Casting With TOSCAST Monitoring System

ELK GROVE VILLAGE, IL, November 4, 2021 - What goes on between one operator and the die casting machine should never be left a surprise to the next shift operator. While most factories have a process in place to record what took place the shift before, som...

Read moreShibaura Machine Makes it Simple to Match the Die to the Machine

ELK GROVE VILLAGE, IL, September 7, 2021 - Being successful in die casting is a combination of efficiency and productivity. Being able to be a step ahead of where your competition is at and exceed customer expectations requires it. One way to gain an advan...

Read moreImproving Efficiency in Die Casting with Shibaura Machine's Integrated Cell Management Solution

ELK GROVE VILLAGE, IL, Aug 19, 2021 - Die casting is a complex process. In the early days that meant dividing all the tasks into separate rooms, but as technology advancements have been made the entire process often happens under one small section of floor...

Read moreThe Importance of Details in Die Casting

ELK GROVE VILLAGE, IL, Aug 5, 2021 - At a busy foundry it can be easy to let small details become an oversight. From tasks like checking the alloy, temperature, and even ladle cup size- this can seem time consuming in the moment. However, those details are...

Read moreWhy Reliable Temperature Control is Critical to Your Die Casting Success

ELK GROVE VILLAGE, IL, July 22, 2021 - What does temperature have to do with it?If you’re involved in die casting production then you know it's everything. Even a slight fluctuation in temperature can mean major damage and defects. Ensuring a well-controll...

Read moreWhen is Waste Not Truly Waste in Die Casting?

ELK GROVE VILLAGE, IL, July 08, 2021The green movement is more important than ever before. No industry is overlooked, and it is every company’s duty to make changes to support the environment. In die casting that often means eliminating excess production a...

Read moreShibaura Machine Makes Die Casting Record Keeping Easy

ELK GROVE VILLAGE, IL, May 6, 2021Back when die casting first began the machines were operated by hand turned valves and timers, left in the hands (and head!) of the operator. Each operator had their own preferred list of turns on the valves and times to m...

Read moreShot Cylinder Construction is More Important Than One Would Think

ELK GROVE VILLAGE, IL, April 15, 2021Have you ever heard the saying that too many cooks in the kitchen spoil the broth? This expression can also be applied to die casting machine shot cylinder design. Consider early generation and many current-day die cast...

Read moreDie Casting Factory Accessory Integration Improves Productivity

ELK GROVE VILLAGE, IL, April 2, 2021Die casting has evolved a lot over the past one hundred years. At the beginning it was run solely by what a person could accomplish. Workers were expected to be the timers, electronics, and robots that we now have today....

Read moreMonitoring Repeatability in Die Casting

ELK GROVE VILLAGE, IL, March 18, 2021 The precision in die casting offers high quality, repeatability shot after shot. This repeatable accuracy offers a lower cost of operation and consistency, two things that are important when looking at improving profit...

Read moreDie Casting Machine - Ease of Use: The TOSCAST controller provides easy visibility of real-time machine status

ELK GROVE VILLAGE, IL, February 19, 2021 Die casting still proves to be the most accurate option when it comes to complex cast metal products. However, it is complex process that involves molten metal, high pressures, critical temperature control, and a v...

Read moreIntroducing a More Environmentally Friendly & Energy Efficient Die Casting Machine

ELK GROVE VILLAGE, IL, February 4, 2021 Imagine having the option to turn on and off your die casting hydraulic pump motor instead of having it continuously running. What would that mean to your overall energy consumption and the environmental footprint o...

Read moreTailor TOSCAST to Improve Your Die Casting Productivity

ELK GROVE VILLAGE, IL, January 20, 2021 For years, die casting machines have offered digital control options making operators more efficient and improving throughput, but a gap still exists. These machines can only do so much before a human needs to step ...

Read moreConsiderations for Reducing Die Casting Cycle Time

ELK GROVE VILLAGE, IL, January 5, 2021 When it comes to die casting, cycle time optimization is more than just moving quickly. At first thought, the time required to complete castings should be as short as possible because more money can be made if you pr...

Read moreOur Commitment to Keep Our Die Casting Customers Up and Running

ELK GROVE VILLAGE, IL, December 16, 2020 When the die casting machine is down costs go up.Avoiding costly downtimes and keeping quality levels high starts with choosing the right machine partner. The right partner will not only provide you with a quality d...

Read moreWorking Together to Make Sure Your Die Casting Equipment is Optimally Operating

ELK GROVE VILLAGE, IL, December 8, 2020 As a Die Caster, are You Up To Date on the Latest Developments?In an industry that is continually evolving with technology developments, it can be difficult to keep up with the demands of the industry. However, by ta...

Read moreShibaura Machine has almost 50 years in the United States

ELK GROVE VILLAGE, IL, June 6, 2020 Shibaura Machine has been manufacturing Die Casting Machines since 1953! Established an office in the United States in 1974! Currently with over 17,000 die-casting machines worldwide! Our team averages almost 25 year...

Read moreShibaura Machine Die Casting Offers Used Machine History Reporting Service

ELK GROVE VILLAGE, IL, July 10, 2020 The purchase of a used machine comes with risks! Help mitigate these risks by requesting a free machine history report. Contact us at dc-MachineFacts@shibaura-machine.com before you consider purchasing a used die casti...

Read moreAvoid damage to your machine caused by extended downtime

ELK GROVE VILLAGE, IL, July 10, 2020 If your die casting machines are not under power for an extended period, You must read the following:The below recommendations will help keep your machines in good running condition and minimize unplanned downtime:KEEP...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools